Hi there,

I have a gravity fed system, the boiler is a Baxi Bermuda Back Boiler 552 an the cylinder is a coil type double feed indirect (Dublotank 100).

Today my CH started normally and after an hour I heard a loud noise. At first I did not really pay any attention, but then I noticed that the lights on my programmer (Salus EP200) were off, i.e. CH not activated. No matter what setting I use on the programmer (i.e. ON, OFF or Auto), the LEDs for Hot Water & Radiators do not lit up. The odd thing is that I am no longer able to even change the time & daily programs, even after resetting the device (and even unplugging it).

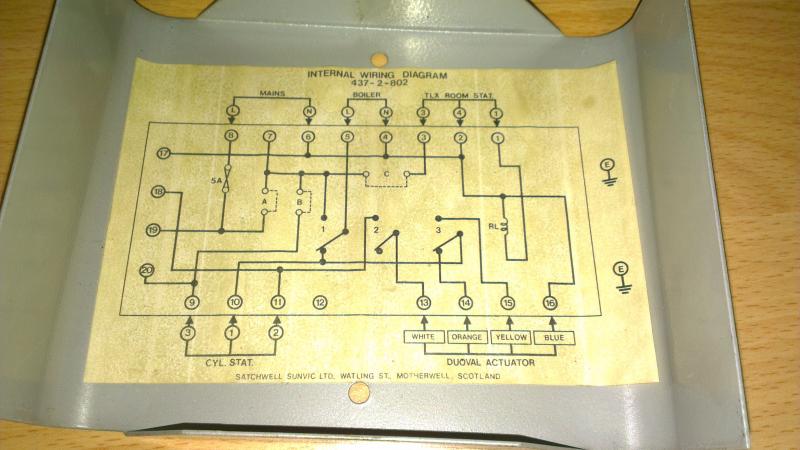

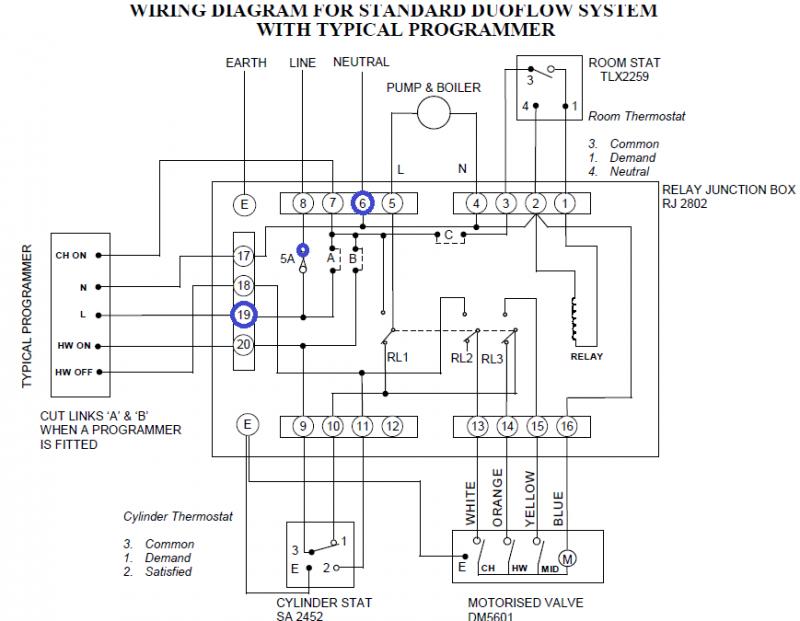

After checking the closet (i.e. where the noise originated from), I noticed that a bit a water was dripping down at the back of the Sunvic DM5601 Actuator. I removed the actuator to access the Sunvic MK1453 valve, I noticed that I can easily turn the valve 360 degrees, is this normal? Or is this valve spring loaded ? (which could explain the loud noise if the spring broke)

Sunvic MK1453 valve:

PS: I tried to remove the 4 screws at the front of the valve, I thought the piece of metal at the front was only used to support the Sunvic DM5601 Actuator, but then lots of water started dripping down so I put back everything in place. I guess I was not meant to do that.

What would likely be the cause of the issue? I am quite worried as I now have no CH nor HW (and this week is going to be quite cold), and the parts are not cheap apart from the programer. Just trying to find out the easiest way to troubleshoot the issue to determine which part needs replaced.

Any help would greatly be appreciated.

Thanks a lot,

Ant

I have a gravity fed system, the boiler is a Baxi Bermuda Back Boiler 552 an the cylinder is a coil type double feed indirect (Dublotank 100).

Today my CH started normally and after an hour I heard a loud noise. At first I did not really pay any attention, but then I noticed that the lights on my programmer (Salus EP200) were off, i.e. CH not activated. No matter what setting I use on the programmer (i.e. ON, OFF or Auto), the LEDs for Hot Water & Radiators do not lit up. The odd thing is that I am no longer able to even change the time & daily programs, even after resetting the device (and even unplugging it).

After checking the closet (i.e. where the noise originated from), I noticed that a bit a water was dripping down at the back of the Sunvic DM5601 Actuator. I removed the actuator to access the Sunvic MK1453 valve, I noticed that I can easily turn the valve 360 degrees, is this normal? Or is this valve spring loaded ? (which could explain the loud noise if the spring broke)

Sunvic MK1453 valve:

PS: I tried to remove the 4 screws at the front of the valve, I thought the piece of metal at the front was only used to support the Sunvic DM5601 Actuator, but then lots of water started dripping down so I put back everything in place. I guess I was not meant to do that.

What would likely be the cause of the issue? I am quite worried as I now have no CH nor HW (and this week is going to be quite cold), and the parts are not cheap apart from the programer. Just trying to find out the easiest way to troubleshoot the issue to determine which part needs replaced.

Any help would greatly be appreciated.

Thanks a lot,

Ant