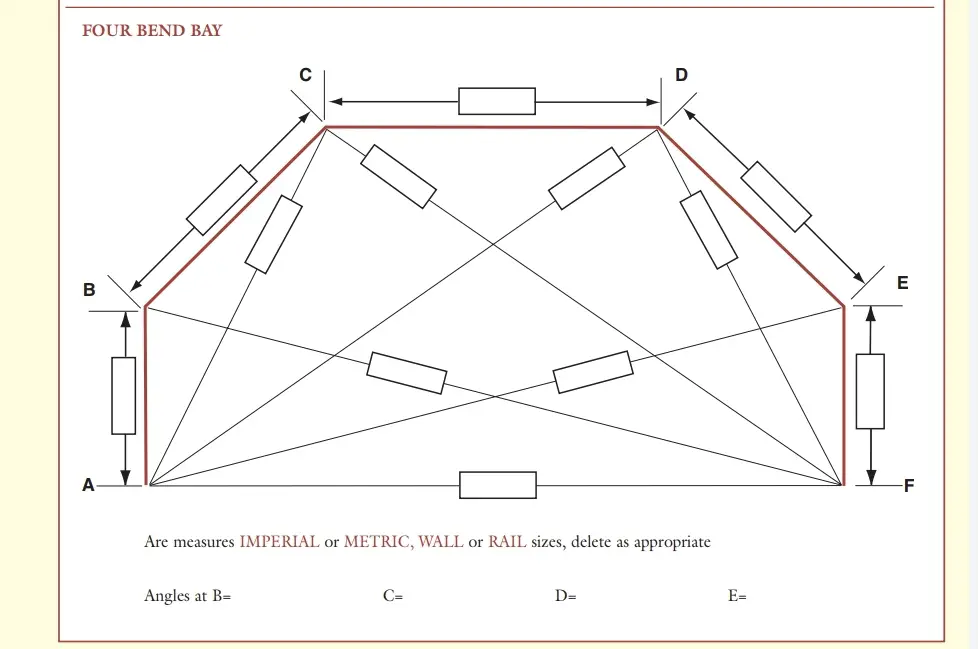

Have a 4m bay, with 4 bends

Wife doesnt like any of the off the shelf bay curtain pole kits and would like a wooden one.

Tracks are not an option, as we are wanting to remove the old plastic ones.

I can only find 2 places selling wood bay poles . One doesnt display prices, the other quote was £450.

How difficult would it be to make one? I can buy cheap wood poles and cut mitres and form the shape. Joining them will be tricky, guessing ill need to bend threaded double ended screws to the correct angle to join them.

Bad idea? Any better ideas?

Wife doesnt like any of the off the shelf bay curtain pole kits and would like a wooden one.

Tracks are not an option, as we are wanting to remove the old plastic ones.

I can only find 2 places selling wood bay poles . One doesnt display prices, the other quote was £450.

How difficult would it be to make one? I can buy cheap wood poles and cut mitres and form the shape. Joining them will be tricky, guessing ill need to bend threaded double ended screws to the correct angle to join them.

Bad idea? Any better ideas?