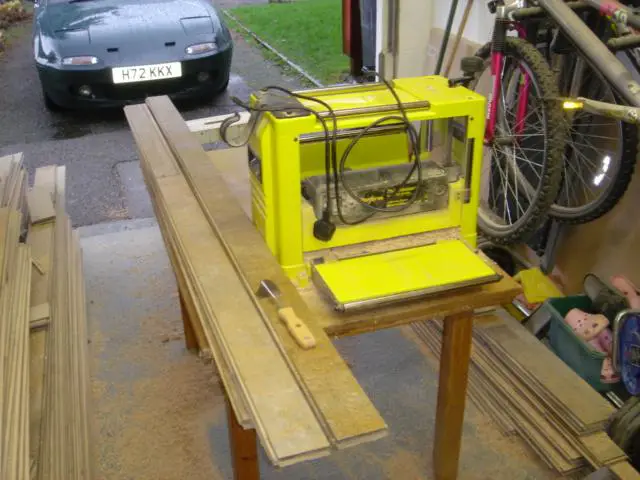

I have finally got to a stage where i can post agian on my floor. Last time i was home i laid 30+sqm in the new extension. I really hope my bletherings below will help someone out down the road. First of all, Axminster tools thicknesser machine(yellow one hobbyist level) is only good for about 60Sqm of flooring through it. The motor burnt out and i had to buy another one(next level up and about £140 i think). I was taking about 1-2mm off in total. It did vary as i was not going for a set finished height but instead removing the old surface to a clean finish and for whatever reason my batch of maple had 2 heights within it with a difference of approx 1mm between the 2 sizes.

After seeking advice on this site i was unsure how to proceed with laying as i was laying the maple onto caberfloor via the secret nailing method and this is largely judged to be a no no as the design of the secret nail is not really sharp and piercing, more wedge like and this can and will blow the back of the caberfloor out. After a bit of thinking i went down the route of marking the placement of

all my subfloor joists in black marker on the caberfloor. I then applied a coat of pva glue to the caberfloor and laid the maple floor secret nailing through to the joists and on occassion just through the caberfloor. The majority of the time the nail took but on a few hits i could feel the floor blow out, no big deal but i now agree with the people who gave me advice and would not rely on secret nails holding over the longterm onto chipboard flooring on their own.

Once laid i then had the problem of the height difference of the flooring to contend with. This turned out to be no problem once i had spent a few hours running from 80 grit down to 120grit on a hired belt sander. I went even more anal than the bare foot test and ended up crawling around on my gel knee pads feeling for differences(yeah i know, i have a wrongness in my head). I then used an orbital edging sander on any bits i did not feel were perfect. To give you an idea of how good the belt sander was i hired it at 13.00hrs and had it back to the hire shop at 09.00 the next day and that was 30sqm of differing height flooring flattened to smooth and goodness me isn't the belt letting go on the sander when worn quite an event?

I ended up going for Junkers acid cataysed floor lacquer, there are 2 types, semi gloss and silk matt. I went for the silk matt and bought 2 of 5ltr tubs from decorating direct along with a couple of 4" harris brushes to apply. 1st coat went on stunning and i could see the potential. Sadly someone in the Junkers factory did not know the difference tween semigloss and silk matt when mine was labelled so the second batch was not silk matt but semi gloss although it was labelled silk matt. My goodness me how i freaked out at that!

In the end Junkers were cool&convinced and they sent me another FOC. So that's where i am now, next time i get onshore(15th May) i will lightly sand to key the flooring and then apply the final coat.

Now i have seen the difference tween semi gloss and silk matt(unintentionally though it may be) i can say that i would go for silk matt every time. It still has a mellow shine to it which compliments the infinite grain patterns of the maple(going off on one am i not). I thought the semi gloss was too 'bright' and concealed through reflection of light a lot of what is going on in the flooring.

I can honestly say that the work needed to turn this flooring from a pile of potential firelighters i bought off a mate to what it is now has been vastly more than i expected BUT i can also say i don't regret a minute of it and it is simply THE most stunning floor i have ever seen(i was not joking about the infinte grain patterns you know). Once i have finished the final coat i will take and post a few pics.

If anyone is thinking about doing the reclaimed maple route i wholehearedly encourage them. Its good for the enviroment(recycling), if its an old enough floor there is no way the grain quality can be matched by what is sold as new today. You WILL learn interesting new swear words and your wife WILL eventually apologise for doubting you the day you brought a load of scrap wood to the house and said 'look what i bought'.

Only another 65sqm to lay in the family room,kitchen and hall now and i can't wait! Cheers. Joe