Hi.

I am just about to drain down and flush my pressurised oil fired home heating system which is situated in my garage (adding a TF1 filter and fresh inhibitor as well.).

After looking at the whole system and trying to plan the job out, I am suspicious of a few things that I have seen, and just wanted to ask for some opinions.

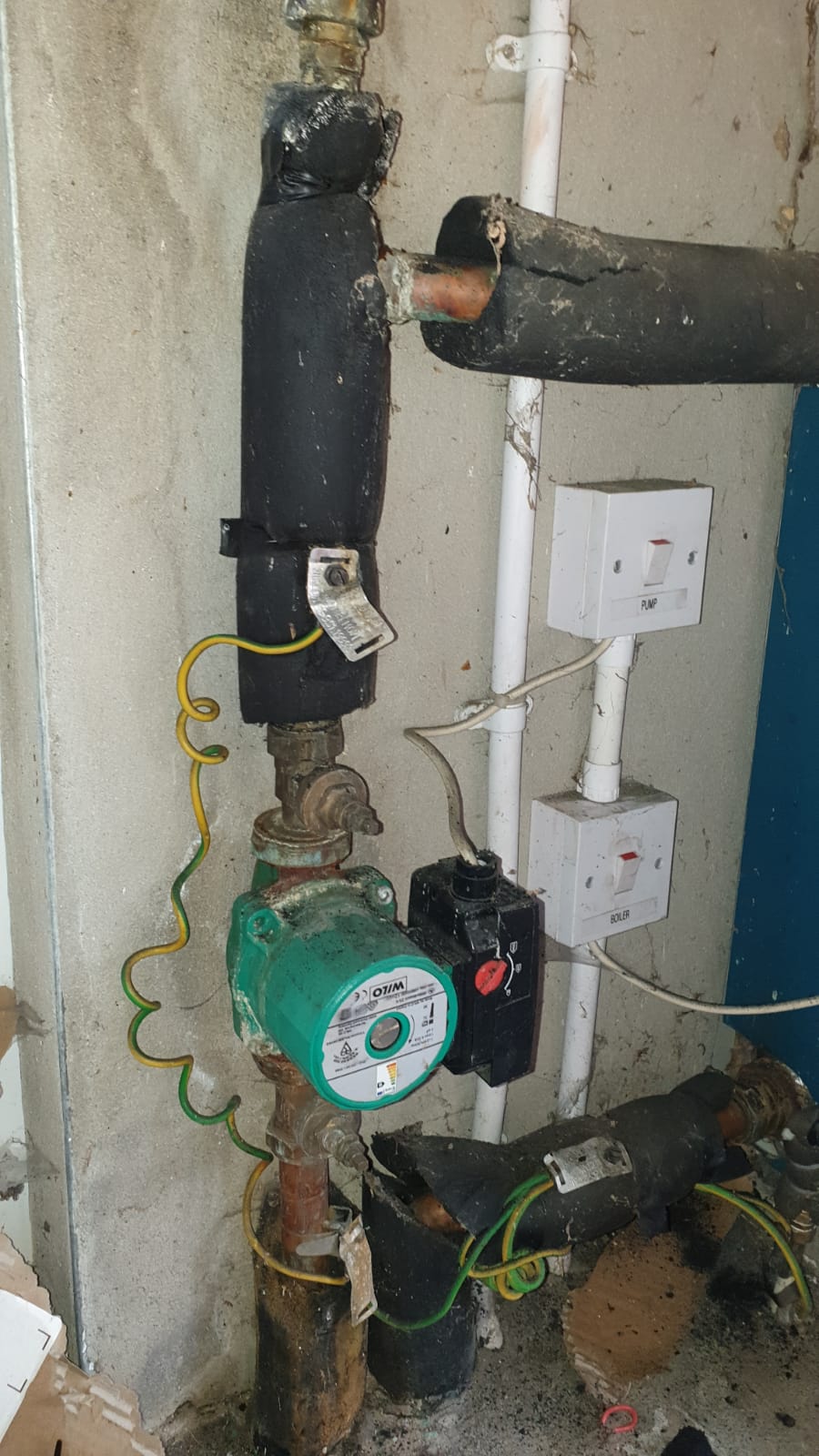

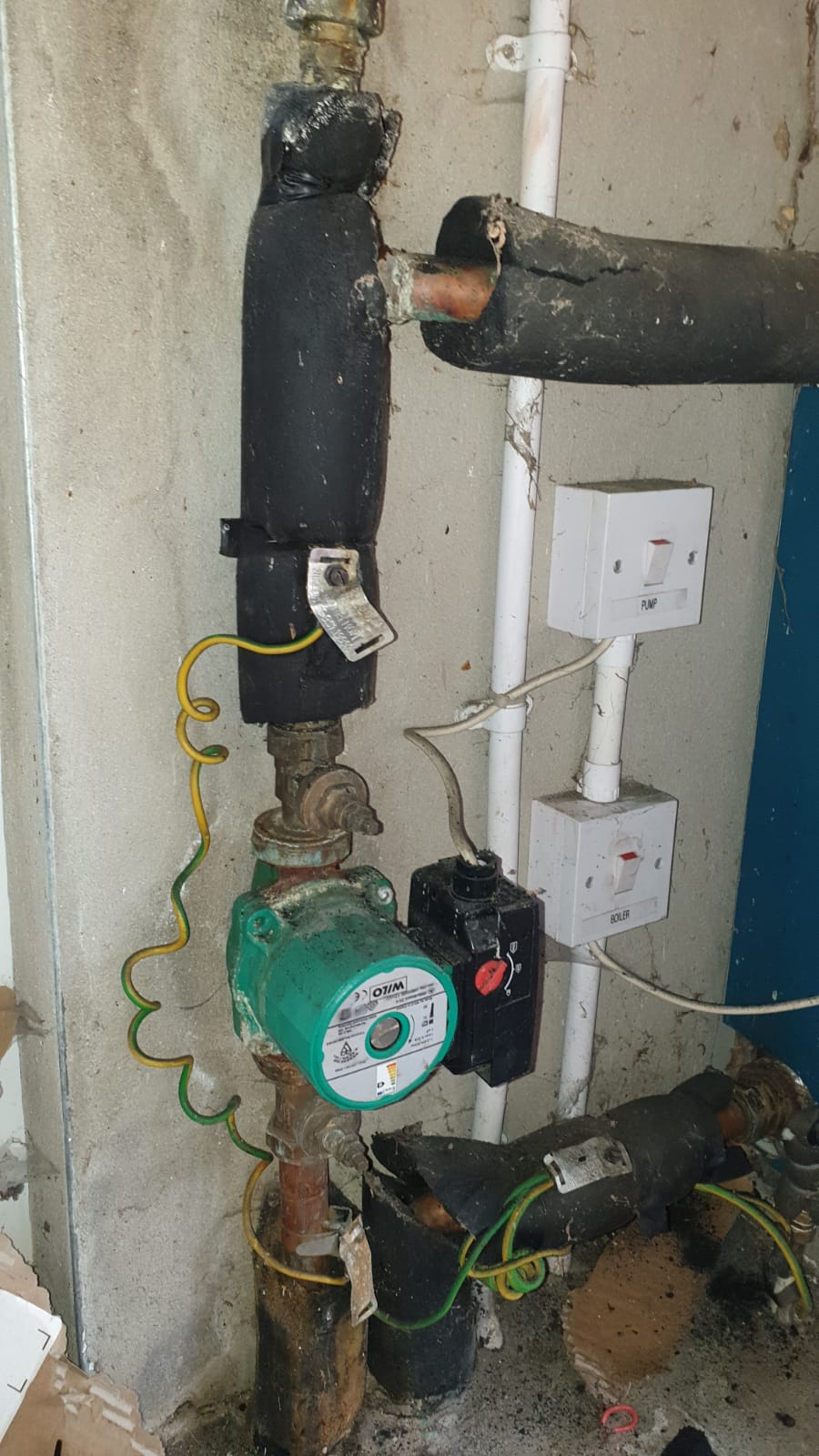

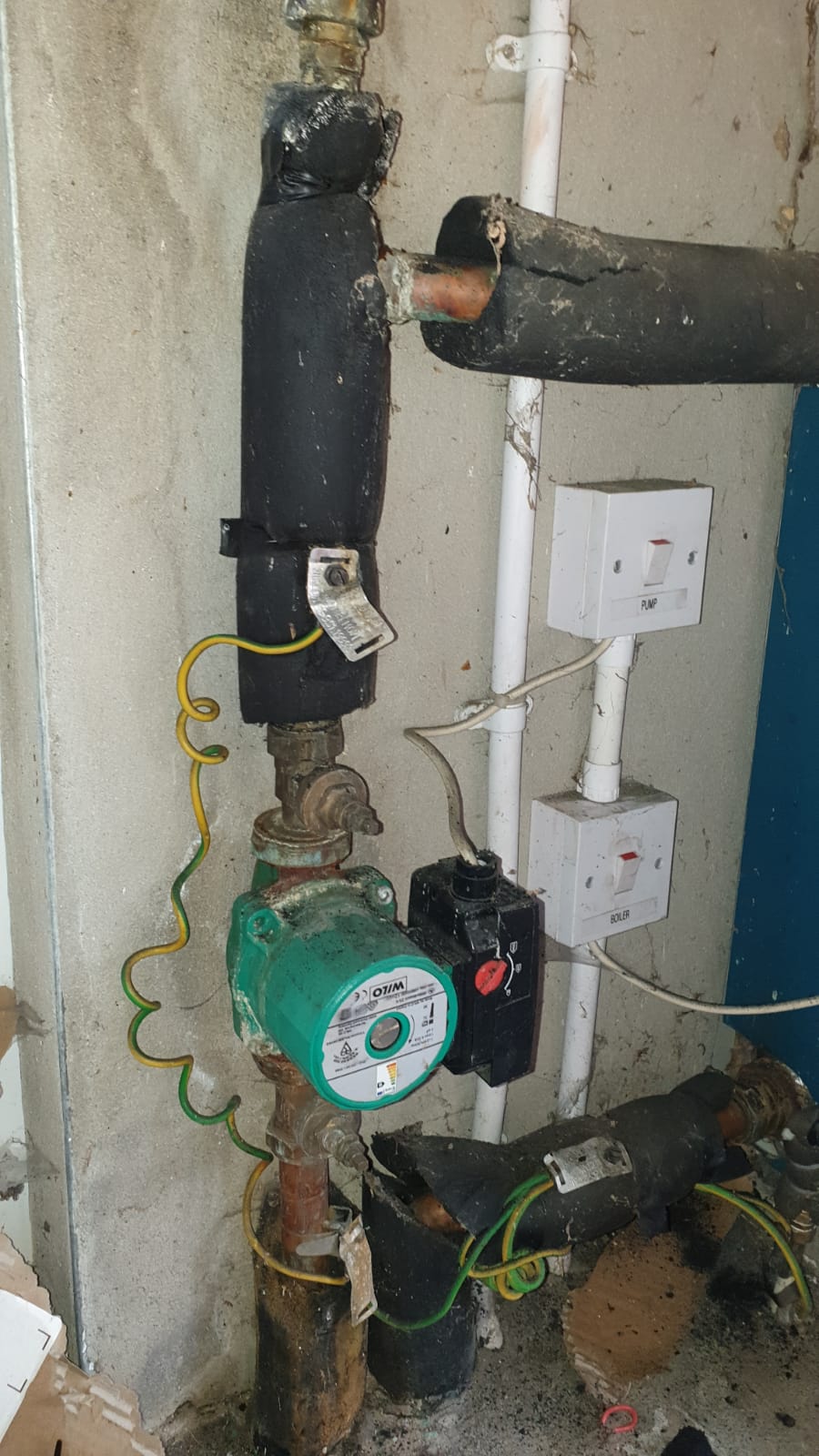

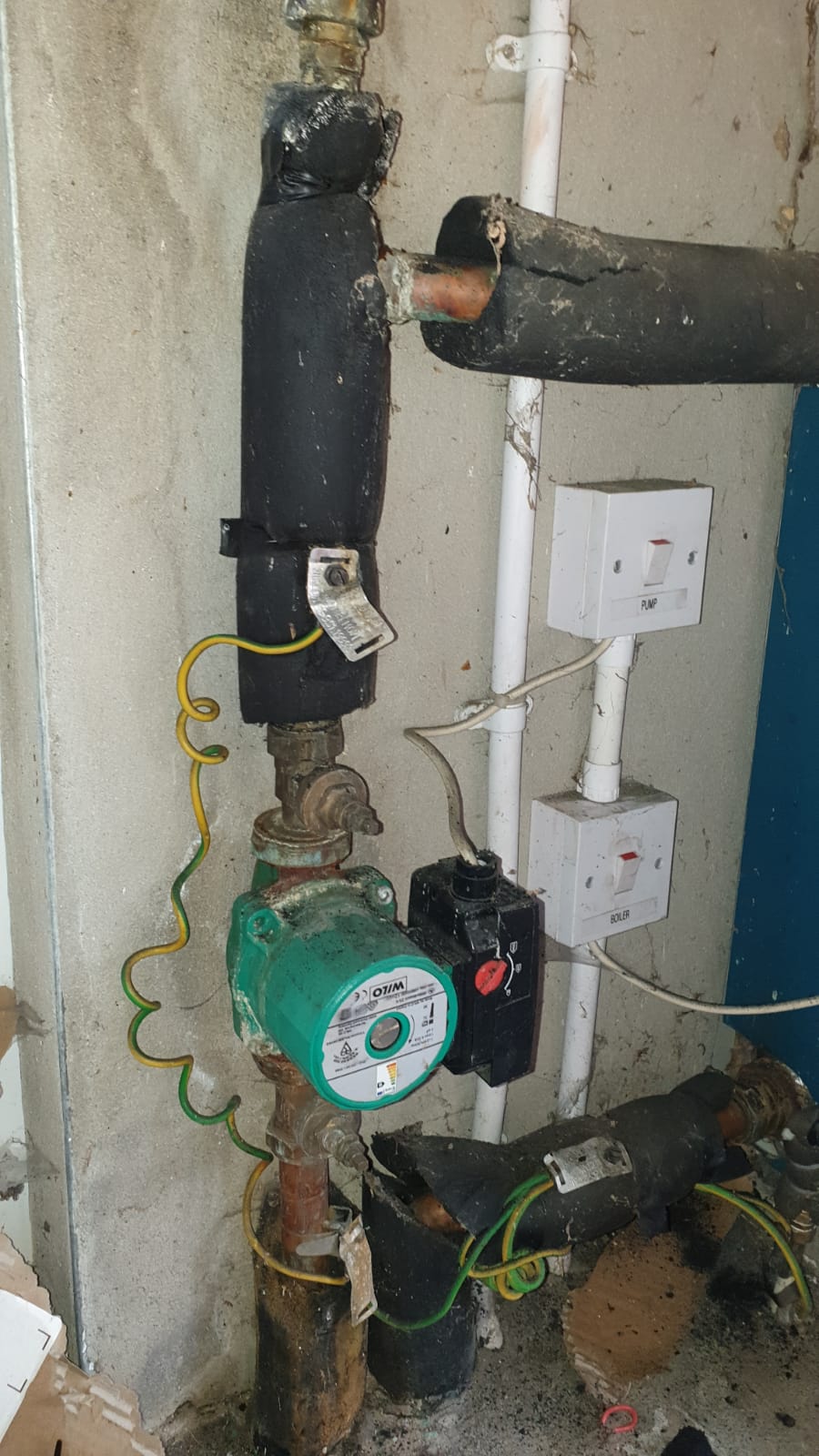

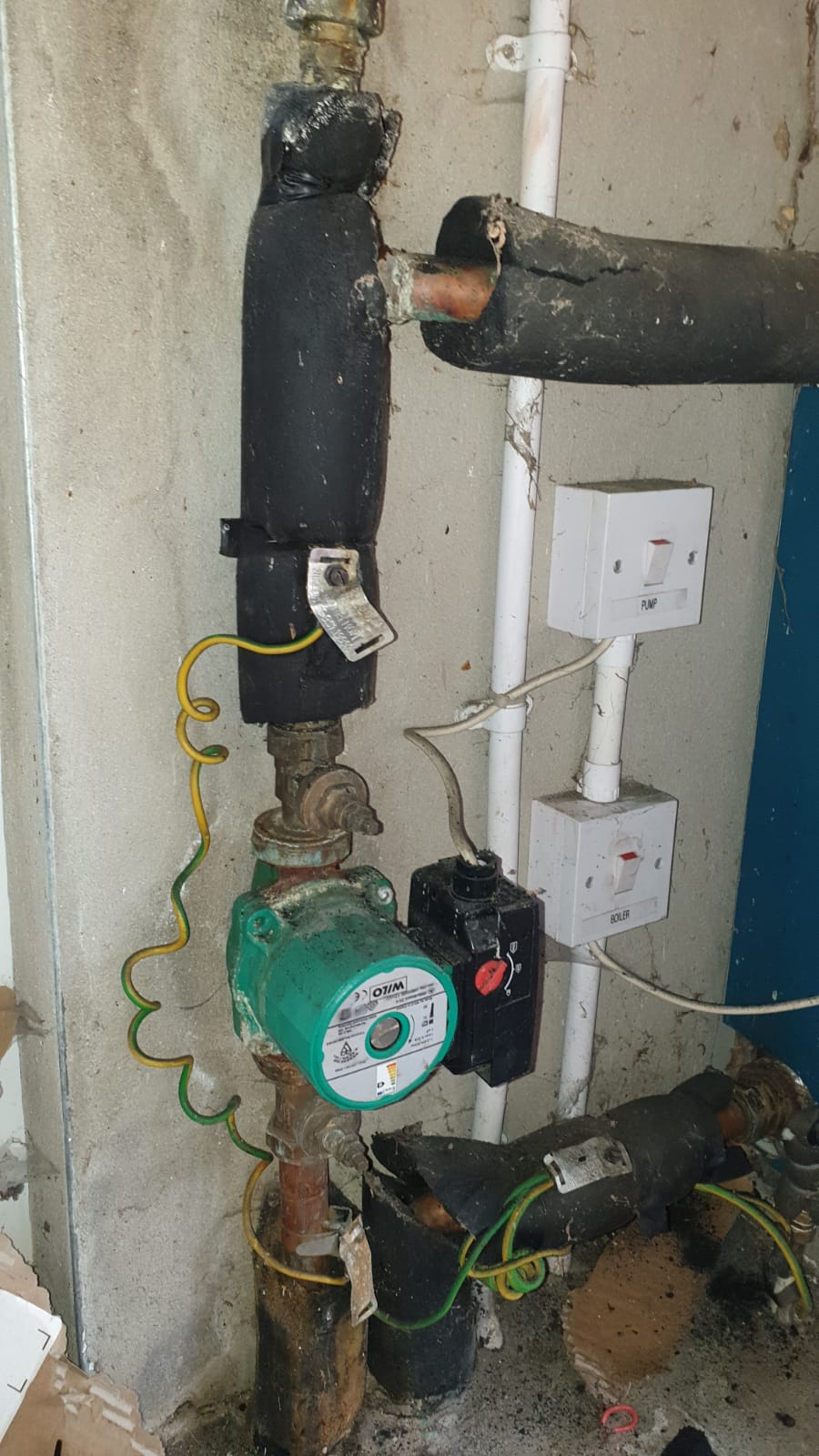

1. The pump is mounted 'upside down'. Ie, the writing on the pump is 180 degrees upside down. I don't know if this is just the pump, or the actual pump casing that it connects to (I understand the casing is directional?), because the actual electric pump could technically be bolted on in 4 different directions? I have attached a photo to see if anyone can tell. (excuse the mess, I am going to tidy this up when draining the system)

2. on the radiators, the return pipes heat up before the feed pipes. (although this is not the case in 1 or 2 of the 16 radiators)

3. There is a constant drip from the Automatic air release valve mounted on a length of 15mm pipe above the pump. I read somewhere if the valve is place above a pump drawing water away from the valve, it can draw in air causing issues? (see pics)

The two 28mm water feed pipes connect top left side and bottom left side of my Warmflow 90/120 oil boiler as you are looking at it. (see pic)

Currently when fired up, the top pipe heats first, the lower pipe after a longer period of time, indicating the flow is from top pipe through pump and into the ground , returning cold to bottom pipe and into boiler. Does this sound right? Is there protocol that the top most pipe would be the hot feed, and the lower pipe the cold return? Unfortunately, I cannot find the installation details for this boiler.

Should the pump be pumping hot water away from the boiler, or cold water into the boiler?

I am also suspicious, because I checked the radiators in the house, and most of them seem to be heating on the return end first, then the supply control valve end. I have no TRVs fitted, just the basic twist and turn valve caps. Of course, the original plumber may have just put the plastic caps the wrong way round on the rads as the brass fittings look identical on the feed and return ends

Is it possible for the heating to have worked for this many years with water circulating the wrong way round? I am also a bit baffled how this would be the case when I have 3 motorised valves (2 heating zones and hot water), because logic would suggest to me that its impossible for the system to flow the wrong way or these motorised valves would not work, given they are connected to the feed only?

I would like sort this all out if it turns out the water is circulating the wrong way round. Would I see any improvements, or indeed if the current flow is wrong, what issues should be apparent?

I take it IF the flow is wrong, then reversing the pump direction would 'cure' the problem?

I am just about to drain down and flush my pressurised oil fired home heating system which is situated in my garage (adding a TF1 filter and fresh inhibitor as well.).

After looking at the whole system and trying to plan the job out, I am suspicious of a few things that I have seen, and just wanted to ask for some opinions.

1. The pump is mounted 'upside down'. Ie, the writing on the pump is 180 degrees upside down. I don't know if this is just the pump, or the actual pump casing that it connects to (I understand the casing is directional?), because the actual electric pump could technically be bolted on in 4 different directions? I have attached a photo to see if anyone can tell. (excuse the mess, I am going to tidy this up when draining the system)

2. on the radiators, the return pipes heat up before the feed pipes. (although this is not the case in 1 or 2 of the 16 radiators)

3. There is a constant drip from the Automatic air release valve mounted on a length of 15mm pipe above the pump. I read somewhere if the valve is place above a pump drawing water away from the valve, it can draw in air causing issues? (see pics)

The two 28mm water feed pipes connect top left side and bottom left side of my Warmflow 90/120 oil boiler as you are looking at it. (see pic)

Currently when fired up, the top pipe heats first, the lower pipe after a longer period of time, indicating the flow is from top pipe through pump and into the ground , returning cold to bottom pipe and into boiler. Does this sound right? Is there protocol that the top most pipe would be the hot feed, and the lower pipe the cold return? Unfortunately, I cannot find the installation details for this boiler.

Should the pump be pumping hot water away from the boiler, or cold water into the boiler?

I am also suspicious, because I checked the radiators in the house, and most of them seem to be heating on the return end first, then the supply control valve end. I have no TRVs fitted, just the basic twist and turn valve caps. Of course, the original plumber may have just put the plastic caps the wrong way round on the rads as the brass fittings look identical on the feed and return ends

Is it possible for the heating to have worked for this many years with water circulating the wrong way round? I am also a bit baffled how this would be the case when I have 3 motorised valves (2 heating zones and hot water), because logic would suggest to me that its impossible for the system to flow the wrong way or these motorised valves would not work, given they are connected to the feed only?

I would like sort this all out if it turns out the water is circulating the wrong way round. Would I see any improvements, or indeed if the current flow is wrong, what issues should be apparent?

I take it IF the flow is wrong, then reversing the pump direction would 'cure' the problem?

Last edited: