I have an outside socket that runs from the consumer on its own dedicated circuit (radial) under the RCD protection. The sockets damaged (cracked) so I have a new one to replace it. Its going in the same position etc and I am confident about connecting it all up but I am concerned about the current run of the 2.5 T&E to the actual socket location from the hole in the external wall

At present (I didn't do it) the cable is simply clipped to the external wall from the hole which is filled with mastic to the socket about half a metre and then goes into the socket in the side through the manufacturer supplied 'gland' not sure if thats the correct terminology - just a rubber grommet to me which has been pierced to let the cable through.

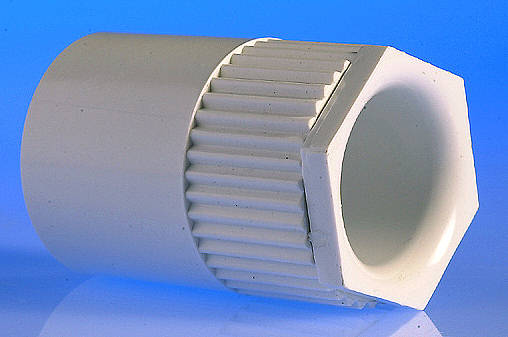

Now my question is, shouldn't the cable be run through the wall in some sort of conduit and then on coming through the wall also run to the socket in some conduit. This would seem safer and more sensible to me and if this is the case I want to do this properly but dont know what sort of thing I should be using. Basically how do I go from the inside then through 90 degrees along the wall to the socket? Assuming this is in some round conduit as I have seen in DIY stores what pieces do I then need to go into the socket. If someone has time to attach links of what I should use for going through the wall, the 90 degree bend on exiting the wall, the conduit from that to the socket and finally into the socket I would very much appreciate it.

Thanks in advance.

At present (I didn't do it) the cable is simply clipped to the external wall from the hole which is filled with mastic to the socket about half a metre and then goes into the socket in the side through the manufacturer supplied 'gland' not sure if thats the correct terminology - just a rubber grommet to me which has been pierced to let the cable through.

Now my question is, shouldn't the cable be run through the wall in some sort of conduit and then on coming through the wall also run to the socket in some conduit. This would seem safer and more sensible to me and if this is the case I want to do this properly but dont know what sort of thing I should be using. Basically how do I go from the inside then through 90 degrees along the wall to the socket? Assuming this is in some round conduit as I have seen in DIY stores what pieces do I then need to go into the socket. If someone has time to attach links of what I should use for going through the wall, the 90 degree bend on exiting the wall, the conduit from that to the socket and finally into the socket I would very much appreciate it.

Thanks in advance.