Hi everyone!

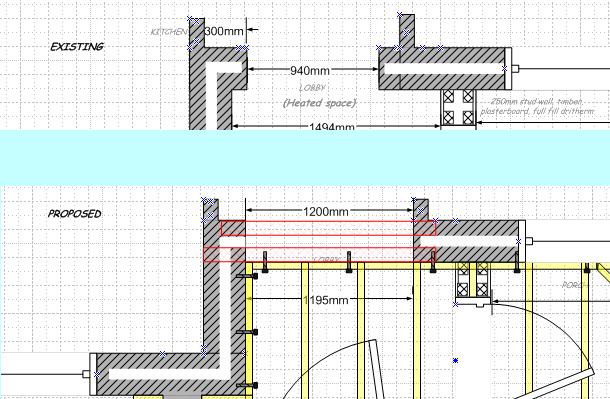

I'm installing a 1500mm cavity lintel. The existing wall has a concrete lintel on the inner skin, and the outer skin only has a door frame keeping it together. I'm widening the structural opening from 1000mm to 1200mm.

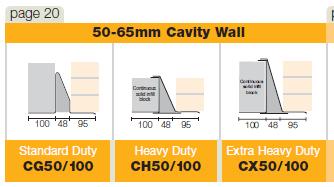

Catnic have recommended a CH50/100 and specified that one side will only have a reduced 100mm bearing due to the way that the wall it's sat on is perpendicular to the lintel direction. You can see what I mean in the picture below.

My question is, what kind of padstones do I need? Both skins are traditional brick. Is the padstone there to distribute the load over a wider area, or to avoid too much mortar directly under the lintel which might crumble over time - i.e. packing out the joint with slate?

Thanks

Gary

(please note, in the diagram below I was considering two box lintels of differing length. Catnic have recommended a single cavity instead, with 100mm bearing on the left, 150mm on the right)

I'm installing a 1500mm cavity lintel. The existing wall has a concrete lintel on the inner skin, and the outer skin only has a door frame keeping it together. I'm widening the structural opening from 1000mm to 1200mm.

Catnic have recommended a CH50/100 and specified that one side will only have a reduced 100mm bearing due to the way that the wall it's sat on is perpendicular to the lintel direction. You can see what I mean in the picture below.

My question is, what kind of padstones do I need? Both skins are traditional brick. Is the padstone there to distribute the load over a wider area, or to avoid too much mortar directly under the lintel which might crumble over time - i.e. packing out the joint with slate?

Thanks

Gary

(please note, in the diagram below I was considering two box lintels of differing length. Catnic have recommended a single cavity instead, with 100mm bearing on the left, 150mm on the right)