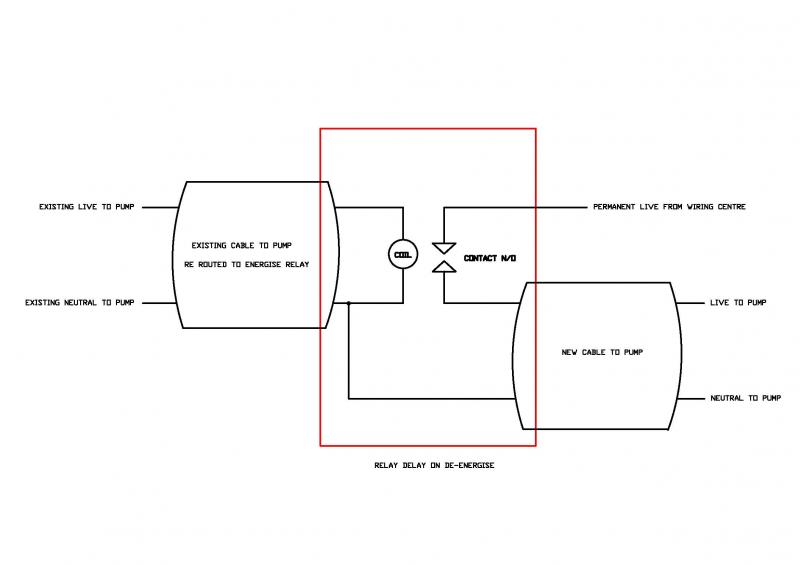

You CAN use the existing switched live as the new switched live and take the permanent live from a nearby mains supply. Its not ideal but as long as the boiler is clearly labeled accordingly it CAn be done.

Alternatively, at additional cost, a wireless operated switch can be used to provide the switched live with the original supply to the boiler connected to provide the permanent live.

Tony

Alternatively, at additional cost, a wireless operated switch can be used to provide the switched live with the original supply to the boiler connected to provide the permanent live.

Tony