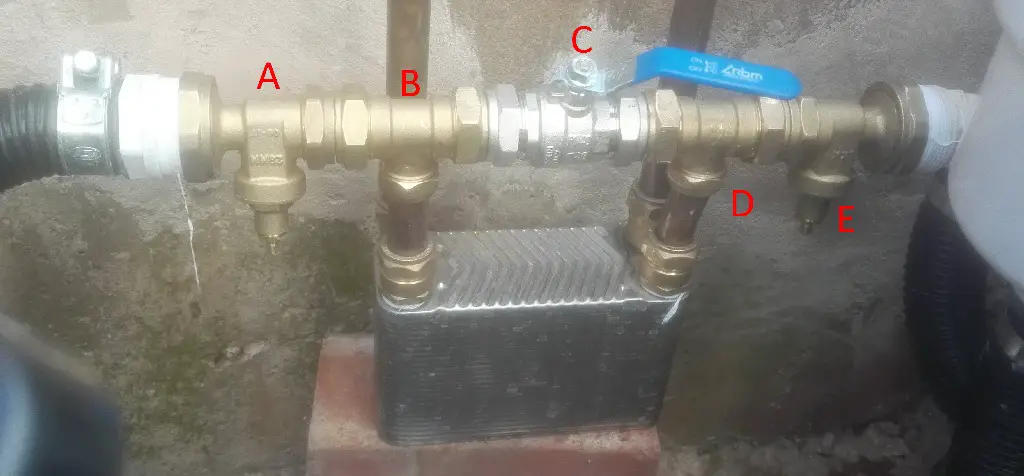

I installed a heat exchanger for my small swimming pool, however I have to balancing incorrect. Whilst it does work it is very sensitive.

A - 1.5" input from 400W pool pump through normal central heating pump valve, restricted flow into 28mm copper (couldn't get full bore from screwfix).

B - 28mm tee with 22mm down to heat exchanger

C - full bore (ish) ball valve

D - tee back up from heat exchanger

E - pump valve back to pool

I get about 80 L/m through to the pool which is about perfect, however small adjustments on valve C equates to heat exchanger being totally off or fully one. The heat exchanger is rated 90KW max but my boiler is currently running at 40KW and I'd like to adjust the flow to close to ideal to maintain a 65'C return temp and keep the flow rate to the pool as high as possible.

What is the 'proper' way to plumb this in?

[EDIT: corrected typo 80L/s to 80L/m)

A - 1.5" input from 400W pool pump through normal central heating pump valve, restricted flow into 28mm copper (couldn't get full bore from screwfix).

B - 28mm tee with 22mm down to heat exchanger

C - full bore (ish) ball valve

D - tee back up from heat exchanger

E - pump valve back to pool

I get about 80 L/m through to the pool which is about perfect, however small adjustments on valve C equates to heat exchanger being totally off or fully one. The heat exchanger is rated 90KW max but my boiler is currently running at 40KW and I'd like to adjust the flow to close to ideal to maintain a 65'C return temp and keep the flow rate to the pool as high as possible.

What is the 'proper' way to plumb this in?

[EDIT: corrected typo 80L/s to 80L/m)

Last edited: