Hello

Am starting a new thread as, based on the advice I got (thank you), I need to upgrade my central heating pipework from 15mm to 22mm.

I'm hoping to find out how much of it can stay and how much of it needs changing.

In total there are 21 radiators totalling 23 Kw, across three floors including loft.

Ground floor: 8 rads 9kW (G1-8). Flow and return pipe run 110m

First Floor: 8 rads plus 3 towel radiators, 11kW (FF1-8 TR1-3) Flow and return pipe run 91m

Loft: 3 rads 3kW (L1-3) Flow and return pipe run 20m

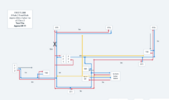

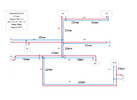

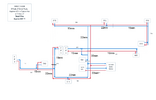

I've cobbled together a diagram which I hope helps. It's not exactly to scale so I've added approximate lengths of pipe run as an indicator .

From what I've read you need have the 'backbone' in 22mm and you don't want 15mm pipe to more than 3 radiators on any one branch, but I'm not sure how close to the radiators you need to get. For example I have a branch (First Floor FF7, FF8, TR3 - Landing, Bedroom & Towel Rad), but the distance is approx 11m - does it all need to be 22mm? It would be great if someone could highlight the areas that need to be 22mm but any advice at all would be gratefully received. Thanks!

Ground floor

First floor

Loft

Am starting a new thread as, based on the advice I got (thank you), I need to upgrade my central heating pipework from 15mm to 22mm.

I'm hoping to find out how much of it can stay and how much of it needs changing.

In total there are 21 radiators totalling 23 Kw, across three floors including loft.

Ground floor: 8 rads 9kW (G1-8). Flow and return pipe run 110m

First Floor: 8 rads plus 3 towel radiators, 11kW (FF1-8 TR1-3) Flow and return pipe run 91m

Loft: 3 rads 3kW (L1-3) Flow and return pipe run 20m

I've cobbled together a diagram which I hope helps. It's not exactly to scale so I've added approximate lengths of pipe run as an indicator .

From what I've read you need have the 'backbone' in 22mm and you don't want 15mm pipe to more than 3 radiators on any one branch, but I'm not sure how close to the radiators you need to get. For example I have a branch (First Floor FF7, FF8, TR3 - Landing, Bedroom & Towel Rad), but the distance is approx 11m - does it all need to be 22mm? It would be great if someone could highlight the areas that need to be 22mm but any advice at all would be gratefully received. Thanks!

Ground floor

First floor

Loft