We have an old Potterton Profile 80e.

Now that the cold nights have started, I've just set the programmer to run the CH.

I've just noticed that the CH pump stops when the boiler cycles to off. Rads take forever to warm up!

The selector switch in the boiler is set to Fully Pumped, so the pump should run all the time the CH is set to be on.

When the boiler cycles on, the pump runs.

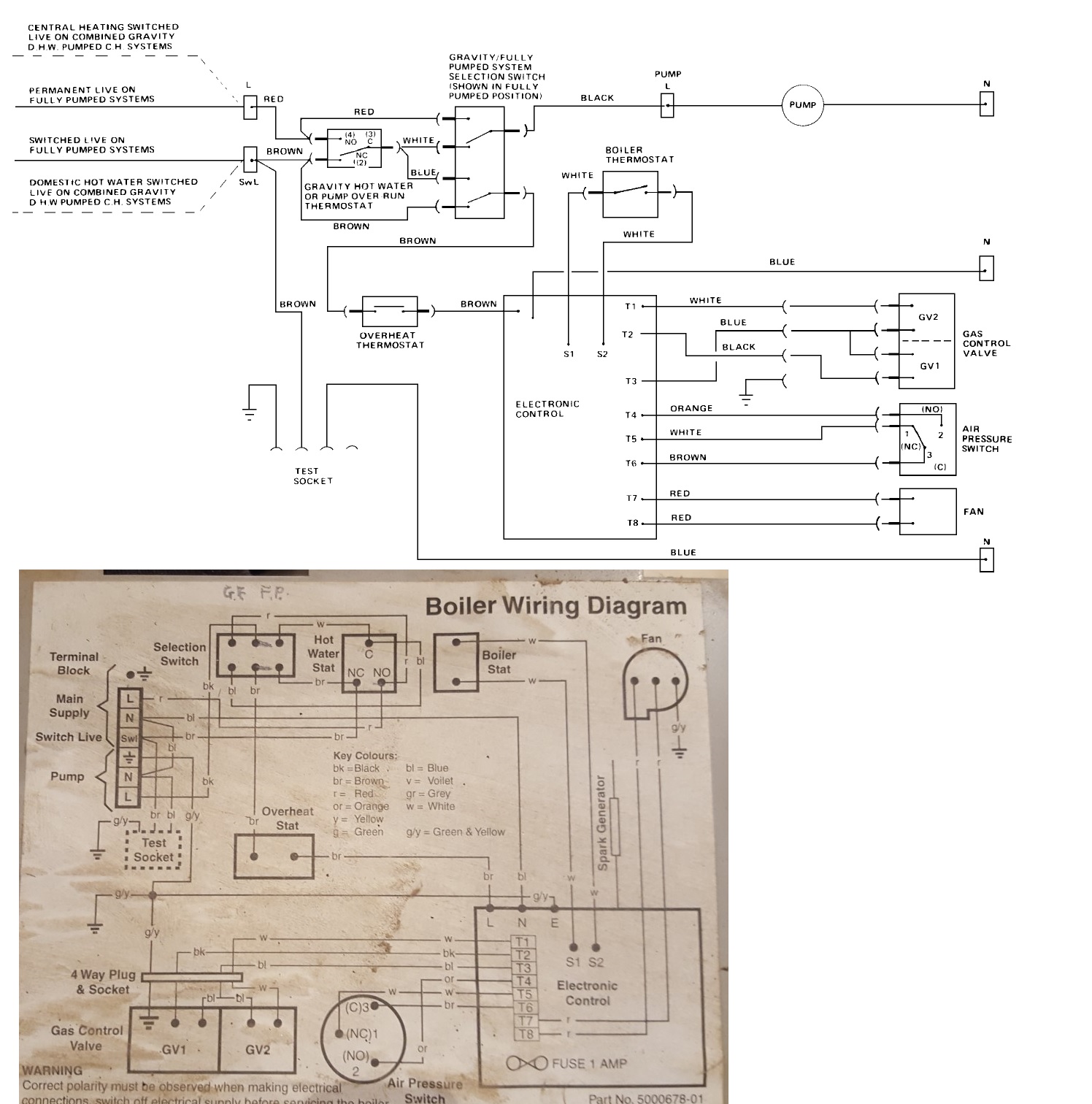

The manual shows the selector switch set to Fully Pumped and the pump connected to the Gravity Hot Water or Pump Over Run Thermostat. Maybe this is faulty?

Looking further at the manual, when the selector switch is set to fully pumped, power for the pump comes from a terminal marked switch live, via the Pump Over Run Thermostat. It says that this is for an external control, which I assume might be a wall thermostat, and if there is no external control, this terminal should be connected to a permenant live.

Checking the wiring, the switched live is connected to a the main 4 core cable that heads up to the airing cupboard where the pump, valves and water cylinder are. This is where the main CH system terminal box is too. The switched live wire is present there in the terminal box but it's not connected to anything else. It's just looped to two other terminals marked Boiler and Pump.

So is it possible that the system has never been wired correctly and the rads will only warm up if there is demand on the boiler for hot water or the underfloor heating system?

Any tips on what to check?

Cheers.

(Boiler schematics below)

Now that the cold nights have started, I've just set the programmer to run the CH.

I've just noticed that the CH pump stops when the boiler cycles to off. Rads take forever to warm up!

The selector switch in the boiler is set to Fully Pumped, so the pump should run all the time the CH is set to be on.

When the boiler cycles on, the pump runs.

The manual shows the selector switch set to Fully Pumped and the pump connected to the Gravity Hot Water or Pump Over Run Thermostat. Maybe this is faulty?

Looking further at the manual, when the selector switch is set to fully pumped, power for the pump comes from a terminal marked switch live, via the Pump Over Run Thermostat. It says that this is for an external control, which I assume might be a wall thermostat, and if there is no external control, this terminal should be connected to a permenant live.

Checking the wiring, the switched live is connected to a the main 4 core cable that heads up to the airing cupboard where the pump, valves and water cylinder are. This is where the main CH system terminal box is too. The switched live wire is present there in the terminal box but it's not connected to anything else. It's just looped to two other terminals marked Boiler and Pump.

So is it possible that the system has never been wired correctly and the rads will only warm up if there is demand on the boiler for hot water or the underfloor heating system?

Any tips on what to check?

Cheers.

(Boiler schematics below)