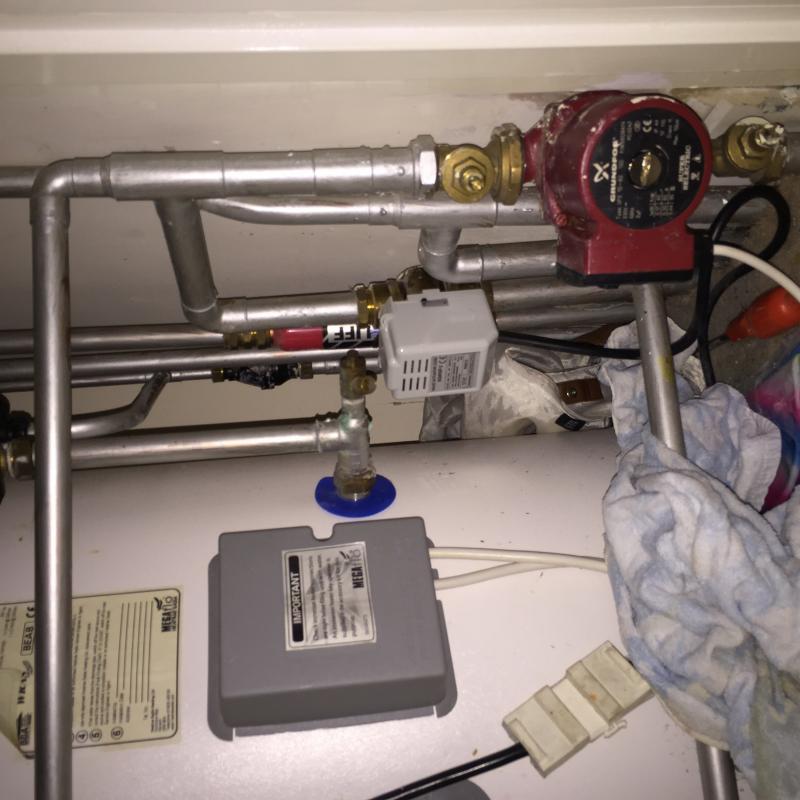

Decided to re-balance after putting in a new pump.

This 12 year old house has plenty of inconsistencies, the flow and return are randomly assigned on each radiator.

I am wondering why on the radiators where the TRV is on the return, why does the flow valve click? It is not a plasterboard heating up clicking, its inside the valve and it sounds like air potentially. Although no air can be bled.

And it happens on all radiators where the TRV is on the return. I simply balanced the flow valve in these cases but doing so produced this noise despite the target temperature drop being correct.

Any ideas what it is and how i should alleviate?

No matter how hard i try my sealed system has gritty noises going through the pump (i do live in a hard water area) and occasionally trickling water sounds in the boiler pipes. I have an AAV and it does work as it went nuts when i swapped the pump. I've checked upper rads for air.

This 12 year old house has plenty of inconsistencies, the flow and return are randomly assigned on each radiator.

I am wondering why on the radiators where the TRV is on the return, why does the flow valve click? It is not a plasterboard heating up clicking, its inside the valve and it sounds like air potentially. Although no air can be bled.

And it happens on all radiators where the TRV is on the return. I simply balanced the flow valve in these cases but doing so produced this noise despite the target temperature drop being correct.

Any ideas what it is and how i should alleviate?

No matter how hard i try my sealed system has gritty noises going through the pump (i do live in a hard water area) and occasionally trickling water sounds in the boiler pipes. I have an AAV and it does work as it went nuts when i swapped the pump. I've checked upper rads for air.