Hi all,

I'm looking to remove the diagonal struts in the loft as part of a "half-conversion".

I did some time ago instruct a SE to do the calculations for this alongside some other works about a year ago. I'm now in a position to start, so have started to look at these in detail.

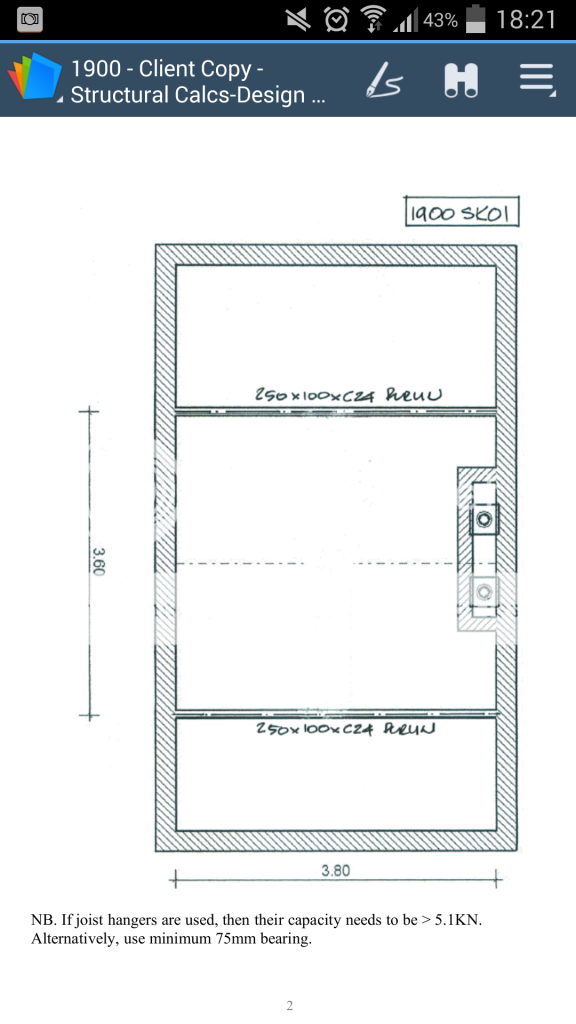

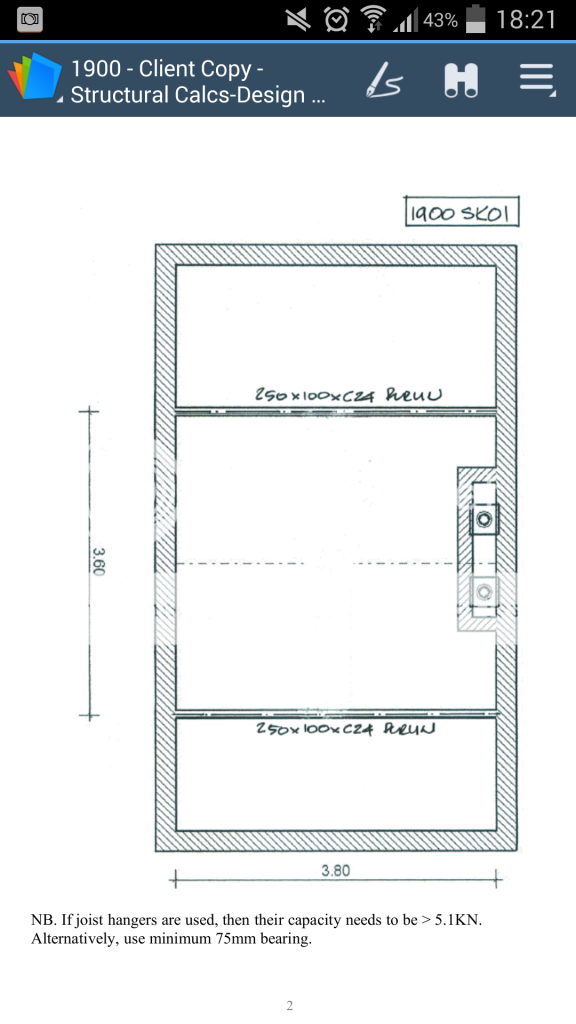

The property is a 1903 terrace, with one purlin on each side supported by a diagonal strut. The support and purlin themselves are "2 by 4".

The SE has specified a C24 250mm x 100mm timber, which seems huge to the point I'm struggling to find somewhere that has them. I also have no idea how such a timber would get into the loft. Had I noticed this at the time I would have probably asked for an RSJ that could be assembled in the loft.

Does the specified timber seem excessive, or is that fairly standard? If I was going down the RSJ route, I assume a smaller sized steel would be required?

Any thoughts welcome.

Excuse the mess, everything has been thrown up in the loft whilst rest of the house was being done!

I'm looking to remove the diagonal struts in the loft as part of a "half-conversion".

I did some time ago instruct a SE to do the calculations for this alongside some other works about a year ago. I'm now in a position to start, so have started to look at these in detail.

The property is a 1903 terrace, with one purlin on each side supported by a diagonal strut. The support and purlin themselves are "2 by 4".

The SE has specified a C24 250mm x 100mm timber, which seems huge to the point I'm struggling to find somewhere that has them. I also have no idea how such a timber would get into the loft. Had I noticed this at the time I would have probably asked for an RSJ that could be assembled in the loft.

Does the specified timber seem excessive, or is that fairly standard? If I was going down the RSJ route, I assume a smaller sized steel would be required?

Any thoughts welcome.

Excuse the mess, everything has been thrown up in the loft whilst rest of the house was being done!