Hi

we have a Worcester greenstar 24i boiler (fitted for a number of years that was in the property when we bought it). We had an issue where the radiators were not getting hot throughout the home when we moved in and after tracing the pipework identified that the flow and return pipes were crossed in a couple of locations so we switched the TRV and lockshields on each of the affected radiators and this improved the situation.

However we have since had an extension and as a result have added some extra radiators - this was done by ourselves. The problem we now have is that only some of the radiators are getting hot and although the flow pipe into some of them is piping hot, the radiator stays cold and the flow pipe is cold too.

We also found out today that the boiler is not cutting off when the heating is on, meaning our gas bill will be huge

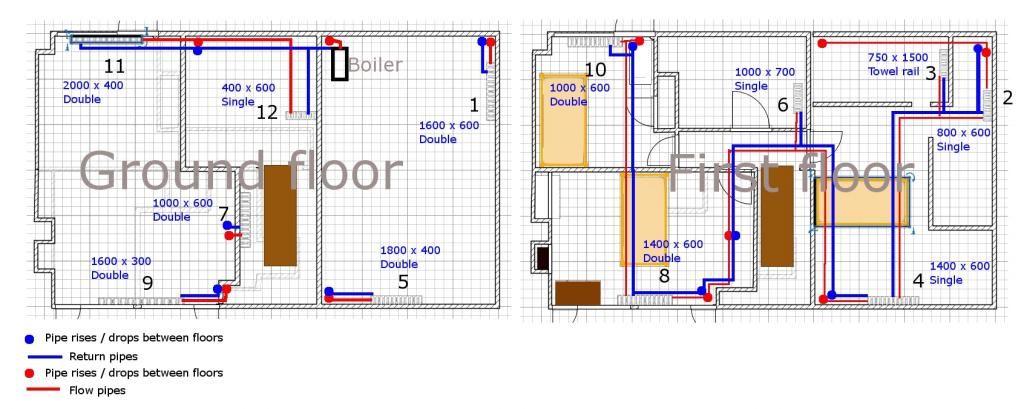

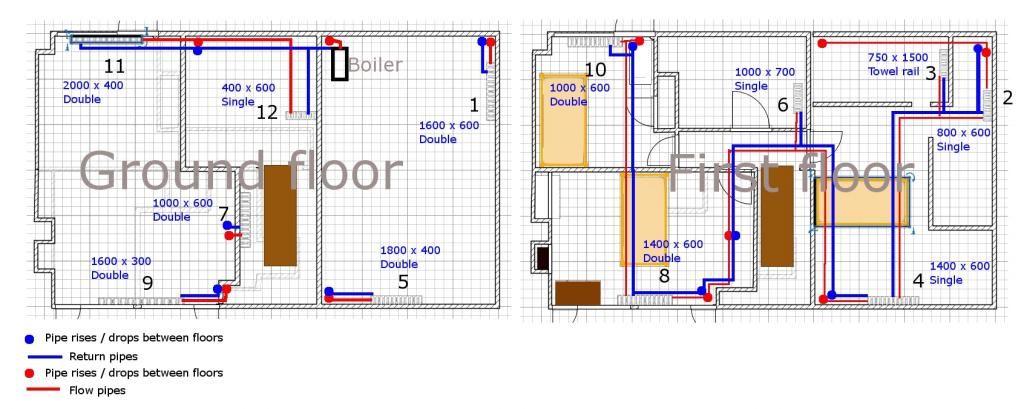

I have attached an image within my album which shows the layout of the home with the flow and return pipes marked and indicated where the pipes drop to feed radiators below.

As it stands currently the following radiators are getting heat at a temp we are happy with

1,2,3,4,5,12

the following radiators are getting some heat but not what we are happy with

6,8,10,11

the following are not getting any heat

7,9

however this is where it gets worse as radiator 7 will; after the heating has been on for a while; suddenly spring into life and 9 has heat at the flow pipe on the TRV but the return is stone cold.

Radiator 12 is heating up (even though it is last on the flow) and the return is red hot by the lock shield but despite it only then travelling approx 7ft back to the boiler the return pipe is only warm to the touch.

We had a plumber call in today and he is baffled but has suggested we loop the flow pipe to the return by the boiler to ensure this flows correctly (ruling out an issue with the boiler) and then if this is ok he would recommend replacing the pipework

I would appreciate any advice as we simply cannot afford to run the boiler constantly, and likewise we cannot have no heating. I have been round and balanced the radiators upto and including 6, and have also restricted the return on 12, but is the current run of pipes set up correctly, as I can not find clear diagrams / guides on this topic and I am wondering if the way the flow is set up is causing an issue

we have a Worcester greenstar 24i boiler (fitted for a number of years that was in the property when we bought it). We had an issue where the radiators were not getting hot throughout the home when we moved in and after tracing the pipework identified that the flow and return pipes were crossed in a couple of locations so we switched the TRV and lockshields on each of the affected radiators and this improved the situation.

However we have since had an extension and as a result have added some extra radiators - this was done by ourselves. The problem we now have is that only some of the radiators are getting hot and although the flow pipe into some of them is piping hot, the radiator stays cold and the flow pipe is cold too.

We also found out today that the boiler is not cutting off when the heating is on, meaning our gas bill will be huge

I have attached an image within my album which shows the layout of the home with the flow and return pipes marked and indicated where the pipes drop to feed radiators below.

As it stands currently the following radiators are getting heat at a temp we are happy with

1,2,3,4,5,12

the following radiators are getting some heat but not what we are happy with

6,8,10,11

the following are not getting any heat

7,9

however this is where it gets worse as radiator 7 will; after the heating has been on for a while; suddenly spring into life and 9 has heat at the flow pipe on the TRV but the return is stone cold.

Radiator 12 is heating up (even though it is last on the flow) and the return is red hot by the lock shield but despite it only then travelling approx 7ft back to the boiler the return pipe is only warm to the touch.

We had a plumber call in today and he is baffled but has suggested we loop the flow pipe to the return by the boiler to ensure this flows correctly (ruling out an issue with the boiler) and then if this is ok he would recommend replacing the pipework

I would appreciate any advice as we simply cannot afford to run the boiler constantly, and likewise we cannot have no heating. I have been round and balanced the radiators upto and including 6, and have also restricted the return on 12, but is the current run of pipes set up correctly, as I can not find clear diagrams / guides on this topic and I am wondering if the way the flow is set up is causing an issue