But I think you are more disposed to explain the reasons why rather than just dismissing my comments.Sorry to disappoint you but I rather concur with the other recent comments above.

I don't know how I could better explain. In the reverse flow flush, there is just the length of flow pipework from the pump to the boiler and then out from the drain just outside the boiler return. I will not be disconnecting the boiler to flush it directly. With the forward flush, the boiler us not included. A valve on its flow is turned off. The flush goes through the pump, through at least one rad, through the Magnaclean and out the drain at the boiler return. I hope this makes sense, but I could draw a diagram. If you follow what I have said, do the flow rates that I measured make any sense?I don't understand any of what you have said about this flushing. I would have liked to see the mains water sent through just the HE without any other pipework and with a high flow rate ideally of over 15 li/min. That would just be to ensure that all the air has been expelled

What are the "three possible loads"?Can you tell me what the flow and return temps are on each of the three possible loads are? Engineers like detailed facts!

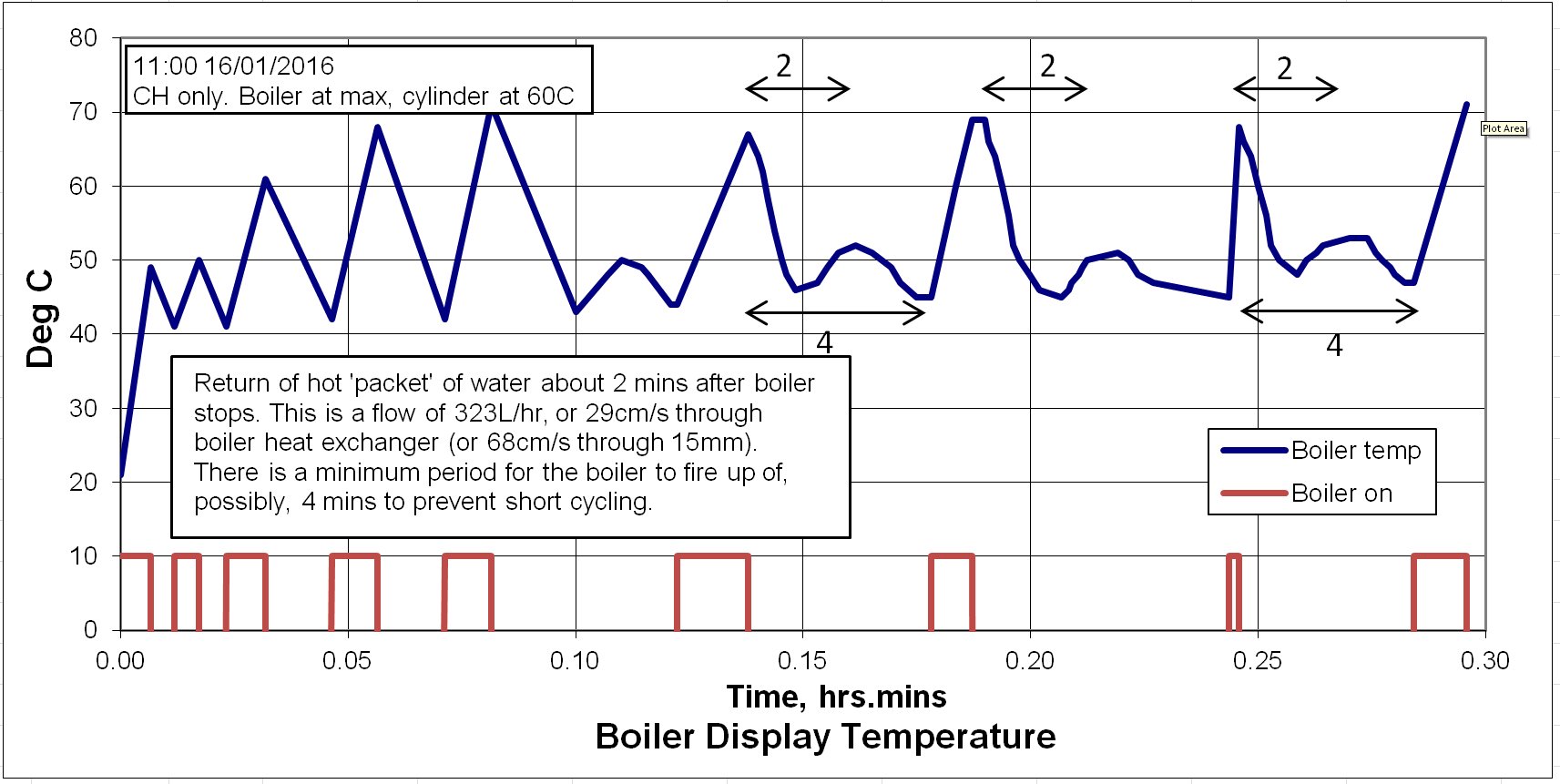

I assume the flow temperature is directly related to the temperature on the LCD. Then, according to the Viessmann engineer, the working temperature difference is 20C. So it seems that flow and return temperatures are linked via software. The Viessmann engineer said that is why the boiler was cutting in at 41C and cutting off at 60C. Was he correct?Unless you know something that I don't, the boiler is mostly concerned with its flow temperature and not its return temperature.

Yes, that is possible - although it did not happen in the previous six occasions. What I now need to do is run the system again with and without the extra lagging to prove this.Now, could whatever flushing that you have done have removed air and caused some improvement in performance?

If the return is 55C (I.e. 75-20), it canI don't see any reason why the boiler should not be able to give a flow temp of 75 C.

Tony