The prices were very reasonable. He did tell me over the phone, but I forget what it was exactly. But it was only a little more expensive than normal spirals and less costly than weights and pulleys. Either way the pricing wasn't a concern for me, I wanted the best thing for the job. He said they typically resupply to manufacturers, than sell to individuals - which is why the website is not setup for end consumers. I wouldn't be buying the part, but going through a manufacturer who offers this.

I visited the first manufacturer,

https://www.timbawood.co.uk, who said they had a problem onsite once with incorrect weighting and could not adjust, so while they would do it if asked they would not recommend it. I also looked at their display and saw a very large distance (far more than the recommended 3mm) around the parting bead and meeting real, so decided not to progress further with them. He said it was a display model, and probably there due to poorer quality - but after my previous problem in that area, I decided not to take the chance - see

https://www.diynot.com/diy/threads/how-to-seal-sash-parting-bead.538544. On the link, they had other issues with windows, supplier refunded me in the end.

It was because of what timbawood said, that has made me want to research this product before committing to it. I was then really surprised that almost none of the UK suppliers use this approach, instead opting for ugly spirals or partial concealed spirals - I couldn't figure out why, as

https://balancesystems.co looks almost perfect. So I wondered what was it I was not getting. But maybe UK markets just do it this way, as it's what they have "always done". You are right, balancesystems, said they are imported from Amesbury Truth. I was looking through the catalogue for the part, as maybe I could find a lot more out there under that name. However the only ones I could see where installed in the jamb and visible rather than the stile, but that might be my lack of knowledge meaning I'm not understanding the products.

I'm hoping to go to the second manufacturer this week who offer this product,

http://www.savethesash.com. But very little details about their windows online. I'm a little obsessed now about a high quality builds, so very cautious of companies that I cannot find mention of, in any of the various forums out there.

I also went to the London show room for

http://www.mumfordwood.com. Their stuffed looked really good, much better than i had installed. Although it was a normal spiral, but partially concealed. Mumford is mentioned a lot in various forums in positive tones, so if they probably offered

https://balancesystems.co I would go with them. What was interesting, for me, is mumfordwood used a strip of velvet around the end of the parting bead, to the side of the vertical draught strip, where it meets the meeting rail. Seems to be going an extra mile for draught proofing, that I had not seen anywhere else. I have UFH in the room, under carpet, so I need to keep airflow change to a minimum.

The last one I want to speak to is

https://westburyjoinery.com as John Mumford joined them, and again I saw positive discussions - but no idea what they are doing with regards to balances and concealment, and if it's different to mumfordwood.

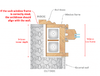

The reason why i'm looking at this, is when we built the new room a reveal was not added to the brick. I was assured with spirals the buildup would not be much. However compared to all my other sash windows below it, that have reveals, it is considerable and looks ugly in comparison. I'm also shocked by how ugly the non concealed spiral was - our bathroom below has a partial concealed spiral. I suspect a poor installation, with additional cladding has exasperated this. So I'm now exploring two options 1) see if a new install and product can match my existing windows on lower floors. 2) add a reveal in the brick, for the new window to be recessed into. If 2 is necessary, I could revert back to pulleys and weights, but I'm tempted to add the reveal and still add

https://balancesystems.co, as long as I can re-assure myself it's the right choice. As this is what the bathroom below has reveal + partially concealed spiral.