Hi all,

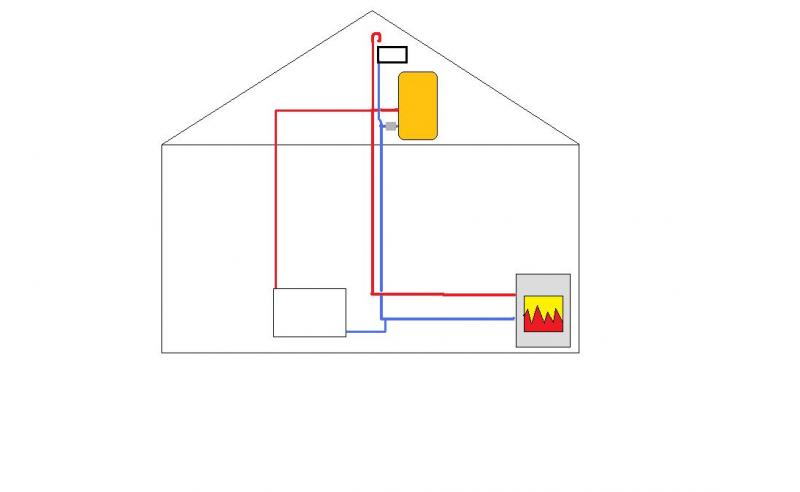

Have a Solid Fuel Fire which heats hot water and heating.

Primatic Cylinder started leaking, so have replaced it with new cylinder, f. & e. tank and cold water storage tank.

Temperature of old cylinder was unregulated, so hoping to fit thermostat to side of cylinder which would shut off a 2 way valve. Central Heating side is pumped, but hot water side was gravity (i think?).

Basically how's the best way to go about doing this? Do I need a radiator connected to hot water side to dump access heat when valve closed?

Cheers

Have a Solid Fuel Fire which heats hot water and heating.

Primatic Cylinder started leaking, so have replaced it with new cylinder, f. & e. tank and cold water storage tank.

Temperature of old cylinder was unregulated, so hoping to fit thermostat to side of cylinder which would shut off a 2 way valve. Central Heating side is pumped, but hot water side was gravity (i think?).

Basically how's the best way to go about doing this? Do I need a radiator connected to hot water side to dump access heat when valve closed?

Cheers