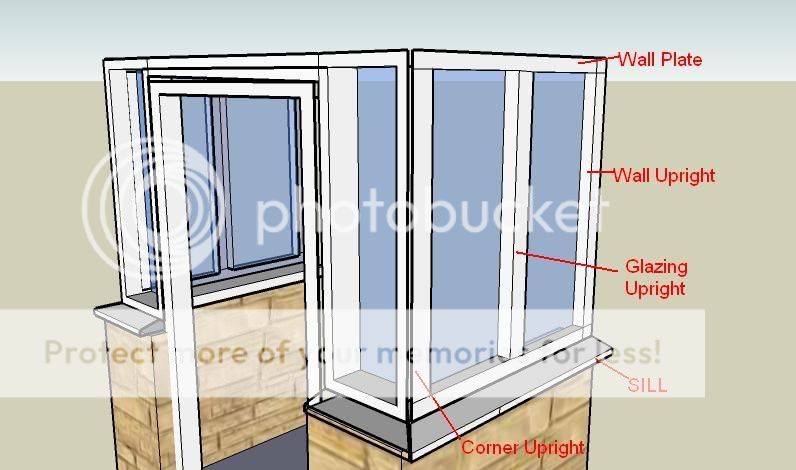

Hi there, am building a porch similar in basic design to the following

The framework will be timber and I'm currently trying to work out what joints to use where and need help with the following:-

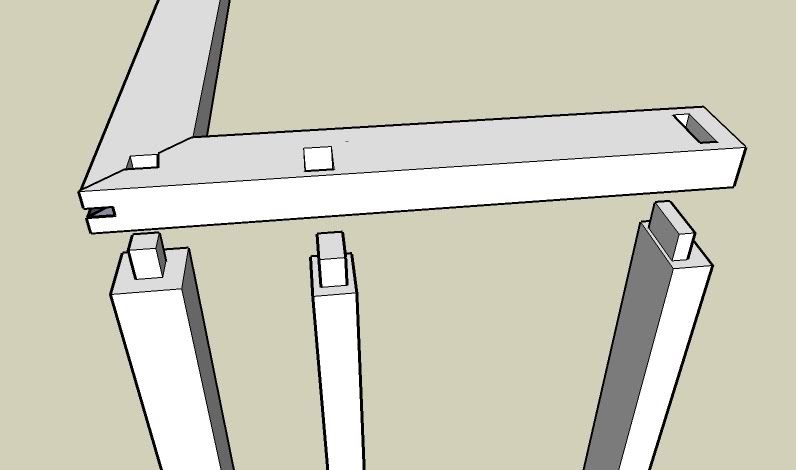

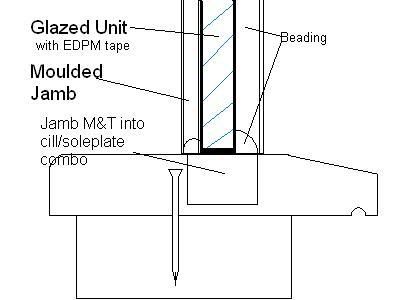

As I cannot seem to find a supplier of a 200x45mm sill I will machine it myself. But cannot work out the corner detail ie how to join the mitred sill parts and join the corner uprights in a strong way. (M&T corner into mitred joint?)

Sill will be frame fixed to dwarf wall and "Wall Upright" will be frame fixed to house wall.

NB Corner upright will be square post not like in sketch.

I will M&T "Glazing uprights" into sill and "wall plate", fine. But how do I join the corner upright to the mitred (and ply biscuited) sill and wall plate.

Also, how do I secure "wall upright" to the Sill and "Wallplate"

"Wall upright" will be bolted to wall

Sorry, if you are as muddled by my description as I am.

So any ideas, any books or websites om framing for a similar porch?

Thanks for your patience,

Tom

The framework will be timber and I'm currently trying to work out what joints to use where and need help with the following:-

As I cannot seem to find a supplier of a 200x45mm sill I will machine it myself. But cannot work out the corner detail ie how to join the mitred sill parts and join the corner uprights in a strong way. (M&T corner into mitred joint?)

Sill will be frame fixed to dwarf wall and "Wall Upright" will be frame fixed to house wall.

NB Corner upright will be square post not like in sketch.

I will M&T "Glazing uprights" into sill and "wall plate", fine. But how do I join the corner upright to the mitred (and ply biscuited) sill and wall plate.

Also, how do I secure "wall upright" to the Sill and "Wallplate"

"Wall upright" will be bolted to wall

Sorry, if you are as muddled by my description as I am.

So any ideas, any books or websites om framing for a similar porch?

Thanks for your patience,

Tom