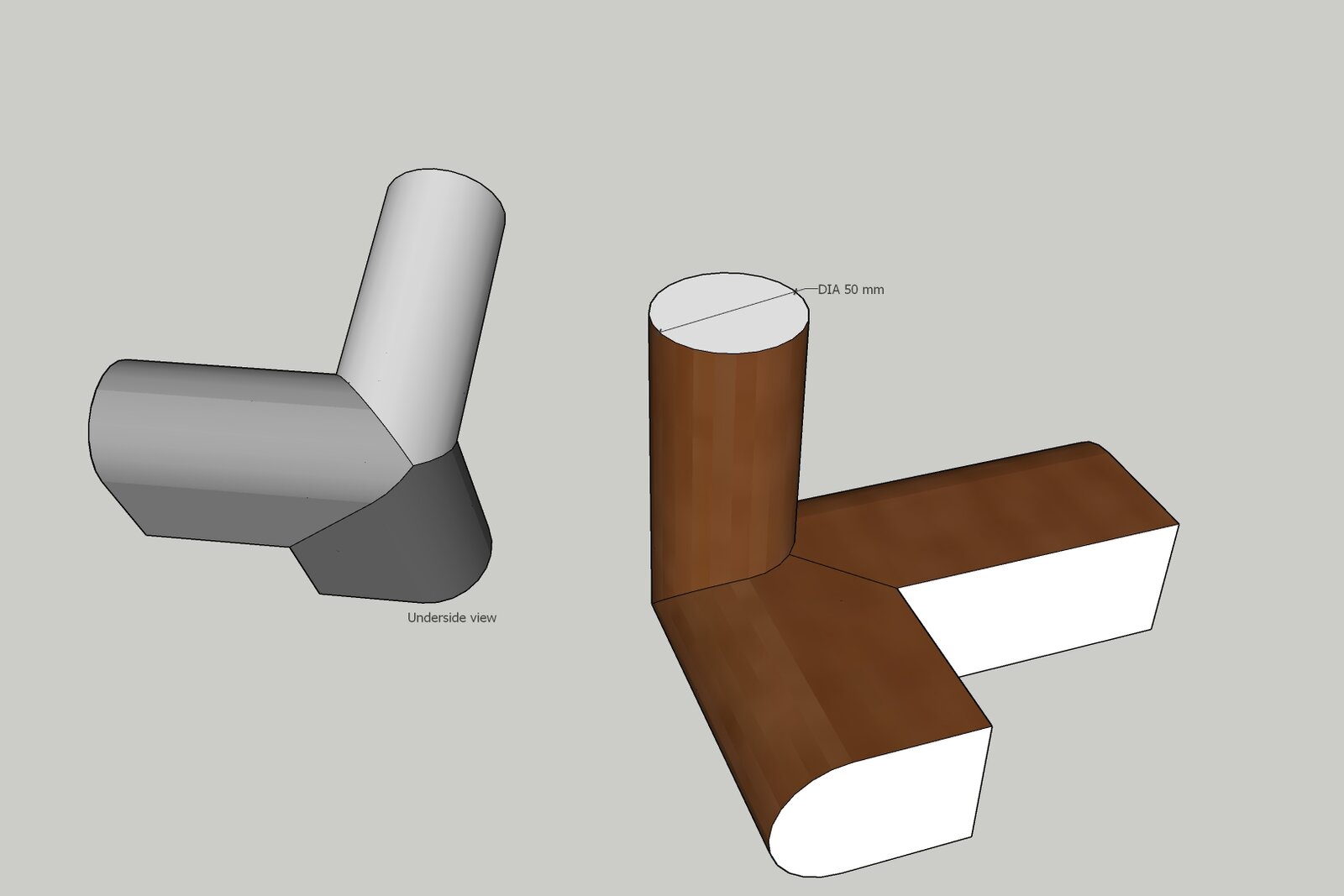

Any bright ideas how to make this joint?

This will be part of an arm of a chair, with the round 50mm section being upright so may get a bit of leverage force applied when in use, and the flatter sections being part of the seat. The grey thing is the same joint but viewed from the underside of the corner.

I'll mitre and either spline or dowel the joint between the bottom two sections, and was just going to dowel the upright piece. But I wondered if just a dowel would be sufficient?

Alternatively perhps a longer steel rod of some sort, and maybe attached to a metal plate on the underside? Not ideal as I would not really want a plate visible.

And while we are at it, any recommendations for the best, strong hardwood furniture glue?

This will be part of an arm of a chair, with the round 50mm section being upright so may get a bit of leverage force applied when in use, and the flatter sections being part of the seat. The grey thing is the same joint but viewed from the underside of the corner.

I'll mitre and either spline or dowel the joint between the bottom two sections, and was just going to dowel the upright piece. But I wondered if just a dowel would be sufficient?

Alternatively perhps a longer steel rod of some sort, and maybe attached to a metal plate on the underside? Not ideal as I would not really want a plate visible.

And while we are at it, any recommendations for the best, strong hardwood furniture glue?