Hello again,

I take the point that with a ring final you have two cables, but one circuit.

Does 2.3.1 of 17ed clarify matters at all? Does the note to 2.3.1 help? Does this help http://www.tlc-direct.co.uk/Book/4.3.5.htm (referring specifically to circuits and not cables in their example).

So I will be permitted to run 2x1.5mm T&E + 1x1.5mm 3 core in the same conduit, provided I adhere to the 43% rule? 4D2A references both 2&3 cores under installation method B. Can you clarify which table is being referred to in note 4 of 4C1. It doesn't mean group factor 0.8 for the 2xT&E and factor 1 for the 1x3core does it? Your interpretation of note four is to treat the combination of 2 core and 3 core cables as being just the same type of multicore cable therefore giving a grouping factor of 0.7? All three 1.5mm circuits will be on individual 6A MCBs so well within permitted corrected CCCs I think, but I would like to understand how to apply the correct calculation for other situations.

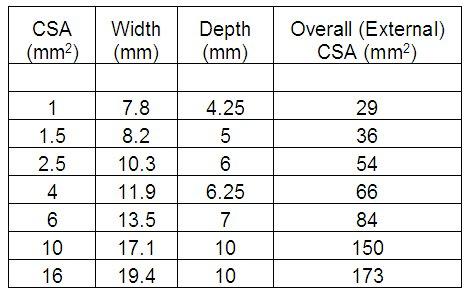

Where can I find the cross section area of the cables to assist in calculating space/filling requirments of the (oval) conduit?

Thanks again.

Lu

I take the point that with a ring final you have two cables, but one circuit.

Does 2.3.1 of 17ed clarify matters at all? Does the note to 2.3.1 help? Does this help http://www.tlc-direct.co.uk/Book/4.3.5.htm (referring specifically to circuits and not cables in their example).

So I will be permitted to run 2x1.5mm T&E + 1x1.5mm 3 core in the same conduit, provided I adhere to the 43% rule? 4D2A references both 2&3 cores under installation method B. Can you clarify which table is being referred to in note 4 of 4C1. It doesn't mean group factor 0.8 for the 2xT&E and factor 1 for the 1x3core does it? Your interpretation of note four is to treat the combination of 2 core and 3 core cables as being just the same type of multicore cable therefore giving a grouping factor of 0.7? All three 1.5mm circuits will be on individual 6A MCBs so well within permitted corrected CCCs I think, but I would like to understand how to apply the correct calculation for other situations.

Where can I find the cross section area of the cables to assist in calculating space/filling requirments of the (oval) conduit?

Thanks again.

Lu