- Joined

- 13 Jun 2015

- Messages

- 5

- Reaction score

- 0

- Country

Good evening,

we are currently in the process of renovating the kitchen in our granite cottage which has necessitated the removal of much of the existing dry lining. I am now in the process of replacing this and upgrading the insulation and would like some guidance on routing the ring within this.

The previous occupants electrician had clipped the 2.5mm T&E for the kitchen/utility room ring directly to the external granite walls. This was the covered with XPS backed plasterboard dot and dabbed to the exterior granite. The cables essentially ran in the 20 - 40 mm airgap (variant as the walls aren't flat) behind the plasterboard.

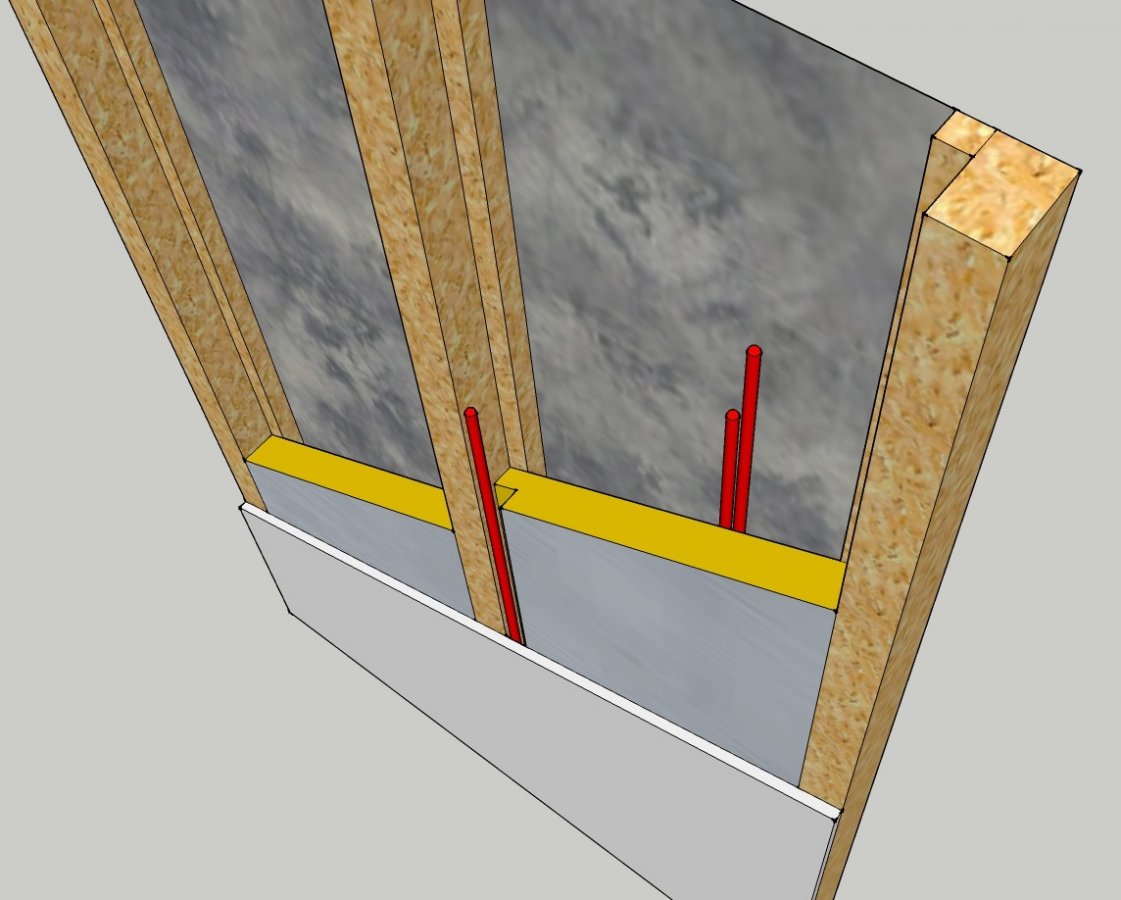

We will be relining the walls using 50mm Kooltherm between 75 x 50 studs, with a 25mm airgap at the rear. Practically, without wanting to run the wires through the insulation, the two options I can see are to stick with the existing method and have the wiring clipped to the exterior wall in the airgap, or to notch out the front face of the insulation and clip directly to the studs. The wires run down from a service void at the top of the wall. Currently the ring is protected by a 32A MCB. Hopefully the sketch below shows what I'm on about...

My concern with option 1 is that it necessitates running the wires through the insulation to reach sockets etc, and with option 2 it is the later danger of screws / fixings running into the cable either when fixing the plasterboard, or more likely in 3 years time when the wife wants a picture moving...

Any thoughts / suggestions would be appreciated.

Many thanks.

we are currently in the process of renovating the kitchen in our granite cottage which has necessitated the removal of much of the existing dry lining. I am now in the process of replacing this and upgrading the insulation and would like some guidance on routing the ring within this.

The previous occupants electrician had clipped the 2.5mm T&E for the kitchen/utility room ring directly to the external granite walls. This was the covered with XPS backed plasterboard dot and dabbed to the exterior granite. The cables essentially ran in the 20 - 40 mm airgap (variant as the walls aren't flat) behind the plasterboard.

We will be relining the walls using 50mm Kooltherm between 75 x 50 studs, with a 25mm airgap at the rear. Practically, without wanting to run the wires through the insulation, the two options I can see are to stick with the existing method and have the wiring clipped to the exterior wall in the airgap, or to notch out the front face of the insulation and clip directly to the studs. The wires run down from a service void at the top of the wall. Currently the ring is protected by a 32A MCB. Hopefully the sketch below shows what I'm on about...

My concern with option 1 is that it necessitates running the wires through the insulation to reach sockets etc, and with option 2 it is the later danger of screws / fixings running into the cable either when fixing the plasterboard, or more likely in 3 years time when the wife wants a picture moving...

Any thoughts / suggestions would be appreciated.

Many thanks.