OK... Here is the charts from a little testing. You owe me two stores worth of water, gas and salt.

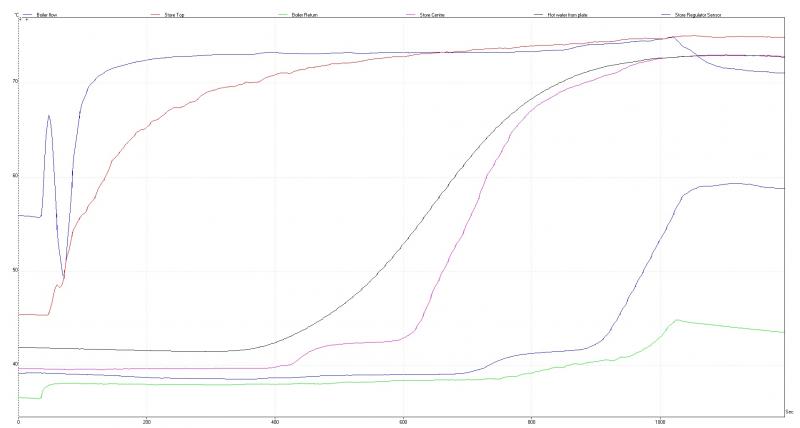

From a cold start, we were on after 30 seconds and switched off at 17 minutes.

Bear in mind, (I assume) due to the way stratification works, my store always shuts down fairly quickly form a cold start.

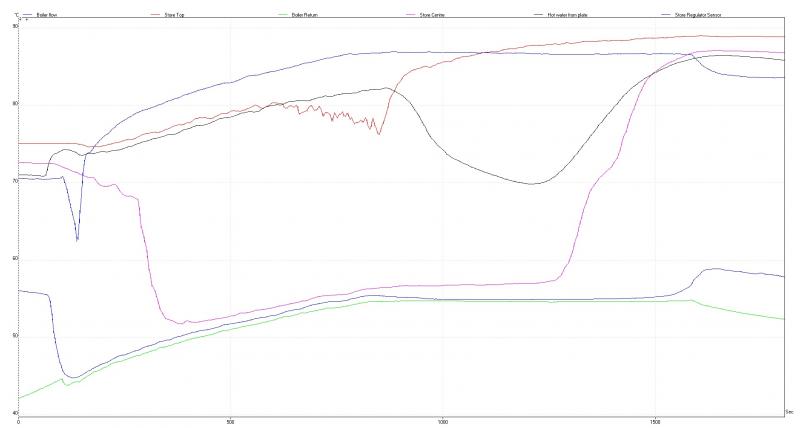

After this period, I let it settle down and then, ensuring no heating could come on went for a long shower.

Water off the plate was blended to 53 degrees. The shower runs at 11 l/min (thought it was higher actually. Must get a bigger shower head).

The shower lasted 13 minutes, but started 60 seconds after the graph started plotting. After 10 minutes I cranked the shower up to about 46 degrees, not sure what the cold inlet temperature of the plate is though sorry. Boiler shut down after 26 minutes:

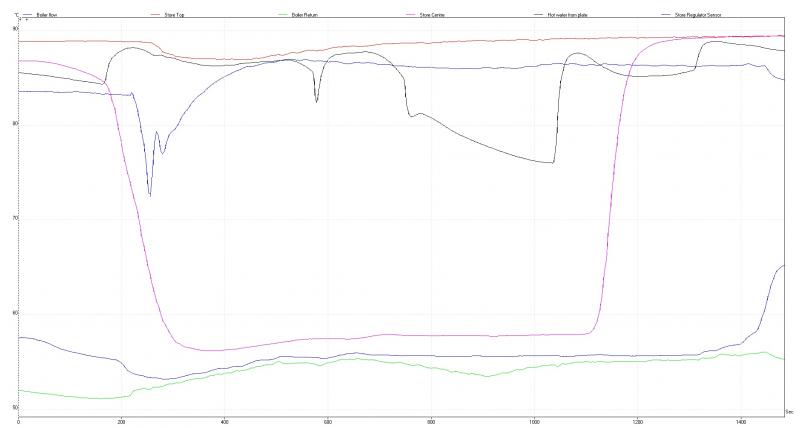

Then the missus had her shower. For this I cranked all the rads up to max at 30 seconds. She started showering at 2:51. The boiler kicked in at 3:40. She finished in the shower at11 minutes and I switched the heating off at 15 minutes. At 17 minutes, for some womean reason she blippe dthe hot water. The boiler shut off after 23 minutes.

Now, the Hot water draw off to the plate is at the same height in the store as the boiler flow and my measurement point. The plate itself is seated just above the centre point of the store. the rad flow is somewhere between the two. In theory, with no draw on either heating or hot water, my plate draw off static temperature should be the same as the centre store temperature.

The boiler return is a little above the heating return; and the store temp sensor is a little above those.

No stupid coils involved. As advised... get the boiler taken out of the equation. It is killing your performance and efficiencies.

If you want the original log files feel free to email me. BTW not sure what version of Pico log you have but the new version is pretty handy compared to the one that came of the CD (release 5.22.2)