Hi all,

I'm currently in conversation with my structural engineer about design and calcs required for creating a 5m gap in the back of my house into a new extension.

He has come up with two options:

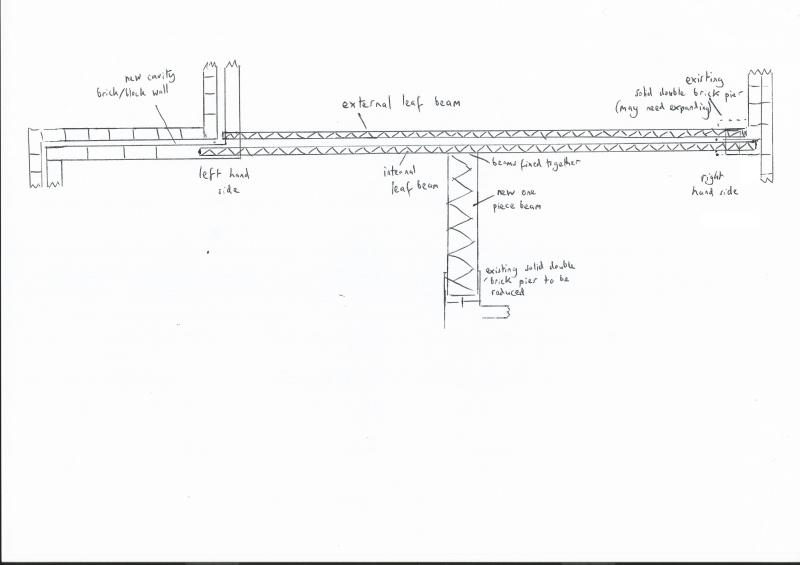

Option 1. This will see two steels. One for the inner leaf and one for the outer leaf. The advantage of this, is that the inner leaf one (which takes more weight) can run further down the blockwork/pads, whilst the outer one will need less overlap with the blockwork/pads. Overall gain is that I don't need a masonry pier that sticks out on the left hand side. Hopefully my sketch below will make what I'm trying to say a lot clearer.

Option 2 is having just a single steel sitting across both leafs (more standard I believe?). The downside of this is that it would require a masonry pillar at the left hand side so that there is enough surface to take the weight. Without a masonry pillar the steel would need to sit on that much of the wall that it would be exposed to the outside.

I've not done this before so I'm interested to hear more experienced views on both options. Option 1 obviously sounds better to me, but are there costs or concerns that I've not thought of?

Many thanks

Jon

I'm currently in conversation with my structural engineer about design and calcs required for creating a 5m gap in the back of my house into a new extension.

He has come up with two options:

Option 1. This will see two steels. One for the inner leaf and one for the outer leaf. The advantage of this, is that the inner leaf one (which takes more weight) can run further down the blockwork/pads, whilst the outer one will need less overlap with the blockwork/pads. Overall gain is that I don't need a masonry pier that sticks out on the left hand side. Hopefully my sketch below will make what I'm trying to say a lot clearer.

Option 2 is having just a single steel sitting across both leafs (more standard I believe?). The downside of this is that it would require a masonry pillar at the left hand side so that there is enough surface to take the weight. Without a masonry pillar the steel would need to sit on that much of the wall that it would be exposed to the outside.

I've not done this before so I'm interested to hear more experienced views on both options. Option 1 obviously sounds better to me, but are there costs or concerns that I've not thought of?

Many thanks

Jon