having some problems with a ufh manifold.

have fitted this 'reliance manifold' for a friend of mine and cant seem to get it to work. its a new manifold - connecting onto an existing ufh setup (external pump and mixing valve)

i'm getting heat to the flow side of the manifold, but nothing coming through the return. have cleared all the air from the pipework in the floor and pressurised the boiler.

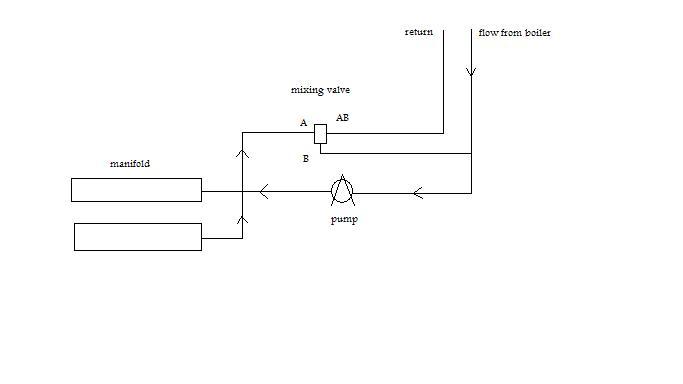

i dont have much to do with ufh, but from what i understand - the flow from the boiler should mix with the return from the ufh manifold and the premix should then enter the flow side of the manifold???

if you can see the crap drawing 'above right' that i've done - then i dont think this is happening. boiler flow goes from the pump straight into the manifold, port A on the mixing valve is the return from the manifold, port b is drawn from the flow and AB (the mix???) returns to the boiler.

the existing manifold did work, and not sure why this one doesnt

any suggestions??????

cheers.