£64? Yikes! The idea was to do this on the cheap. Just add this lot up...

Granite pastry board or piece of thick (12mm plus) float glass with the edges, "safed" - £15

Selection of wet and dry (silicon carbide) papers (£5 to £8 from Halfords or off Amazon) - £5 to £8

Spray adhesive (Poundshop) - £1

Low cost honing guide, e.g Draper, etc - £5 to £8

3-in-1 oil or sewing machine oil (Poundshop although as a handyman I'd have thought you'd have had this) - £1

I make that £26 to £30.

For a start, as an absolute beginner working on your own you really don't want to go the figure of 8 route, simply because you'll end up rounding the blade over and/or getting the edge out of square to the side of the blade. I've taught enough apprentices to know that 2 out of 3 cock it up first time round (meaning that I've needed to grind it straight and start them again). In any case, figure of 8 will quite probably rip your abrasive papers to pieces - the technique is for use with sharpening stones or diamond plates. So I strongly recommend that to start with you stick with the "training wheels"

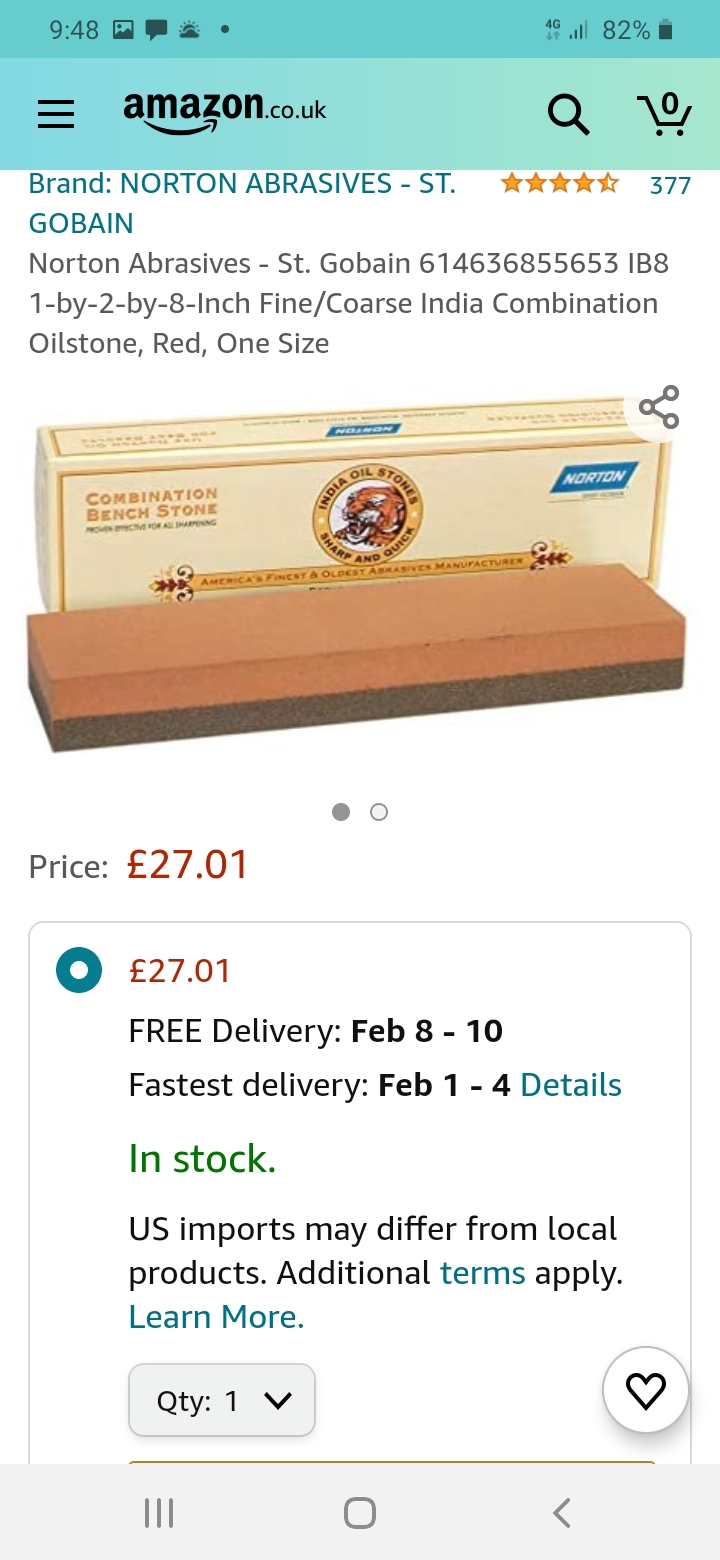

You might want to consider a Norton IB8 8x2x1in combination oilstone (100x/320x grits) or similar (don't buy cheap Chinese carp and avoid waterstones), but remember that milestones hollow over time and as a beginner you have enough to concern yourself with.

Found these-

Is the spray adhesive for spraying on surface before honing? What's the 3 - 1 for as well?

There was a warning about selling to under 18s for adhesive, is it dangerous to inhale require a mask or gloves when using (why such a warning)?

https://www.screwfix.com/p/no-nonse...9S8f_O942ecpvY4FdvBoCl1AQAvD_BwE&gclsrc=aw.ds

I'll buy the setting device and just push the chisel or blade back and forth to sharpen it I guess not too much to it than that.

My Jack plane and block plane although work are jolty and either take off but too much to nothing and blade gets pushed back inside...really want to get sharp too. Will practice honing on an old chisel first though

Last edited: