- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

I have a Vaillant ecoTEC plus 418 on a vented system with twin 2-port valves, ABV, VRC 470f, VR65 and outdoor temperature sensor.

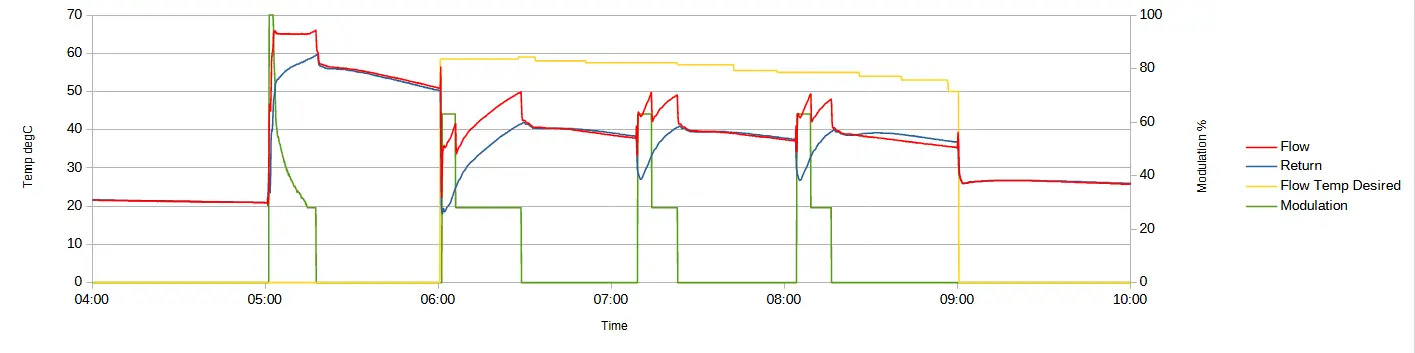

The CH Part Load is set to 5kW. HW is timed to come on at 5am and CH at 6am.

HW is working as I expected but CH cuts off when the flow temp reaches 50C, well below the target set by the controller:

Any suggestions why this is happening please?

Mike

The CH Part Load is set to 5kW. HW is timed to come on at 5am and CH at 6am.

HW is working as I expected but CH cuts off when the flow temp reaches 50C, well below the target set by the controller:

Any suggestions why this is happening please?

Mike