You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vaillant ecoTEC not reaching desired flow temperature

- Thread starter Yikes

- Start date

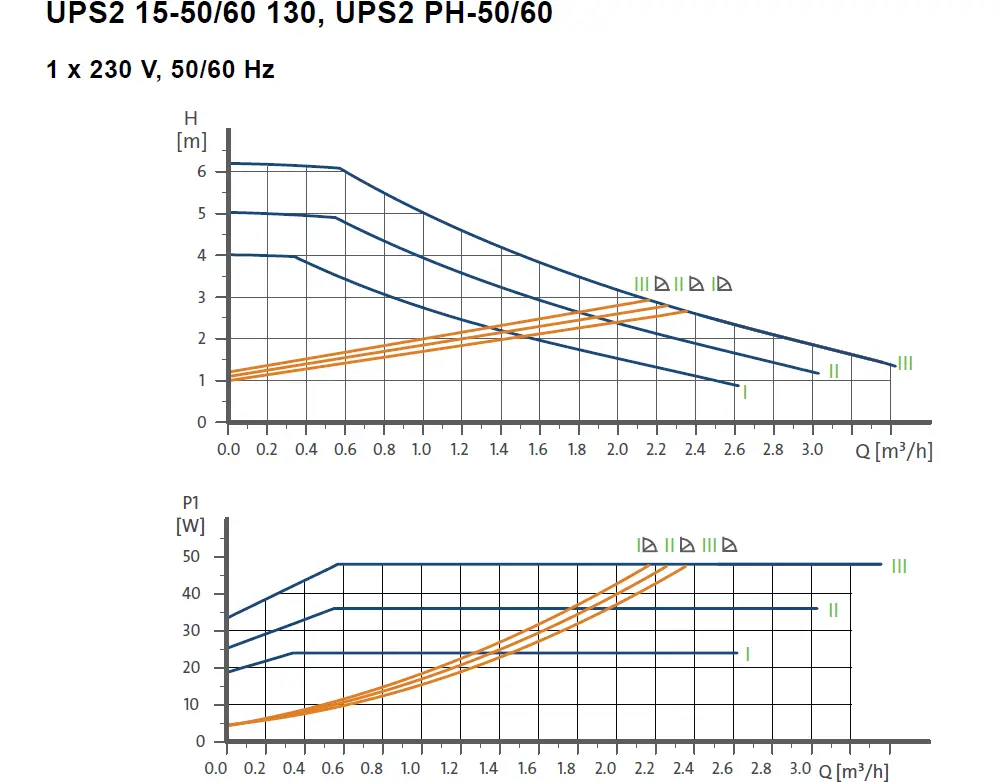

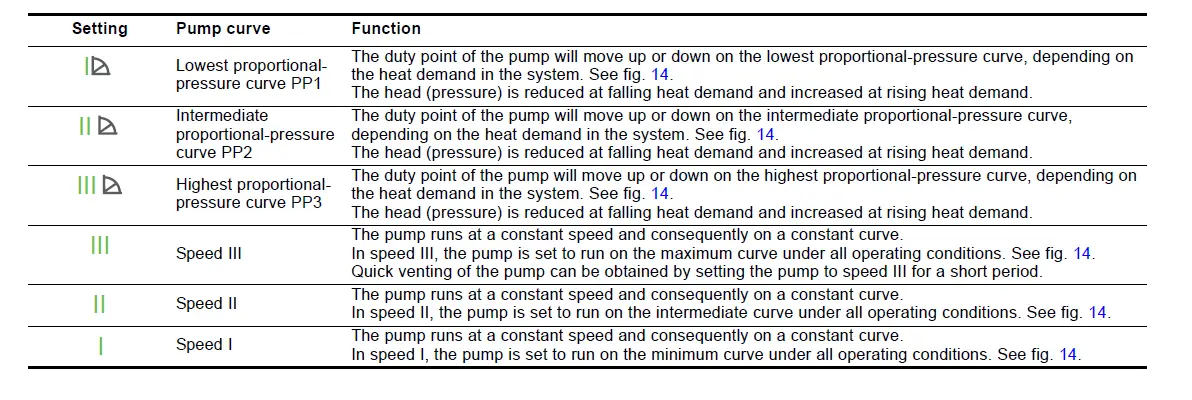

Can't answer that I'm afraid but worth checking out the pump, if you can lay hands on one of those £15 plug in energy monitors, connect the pump cable into it then get a extension lead and plug it in anywhere just before firing the boiler and then read off the watts, these cheap monitors are quite accurate, you can the read off the pump flow from the pump curves, unfortunately, grundfos do not display the pump power in watts.

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

Well it turns out that I was on a wild goose chase with this. I was about to test the pump as you suggested when I noticed that the CH zone valve was stuck half open; the return spring in the actuator was broken. I replaced the actuator, set the boiler back to Flow regulation and the Anticycle time to the default of 20 minutes and now the Desired Flow Temperature is being attained and there were only a few instances of microfiring.

Mike

Mike

Thats great news, but very strange why the ABV wasn't passing as the pump head would/should have been 5M at the reduced flow and the ABV is set to < 3.5M., not sure if your model boiler has a internal bypass, all very interesting anyway and alls well that ends well.

If you have the inclination/time you might do that pump test sometime, if only for interest, all these pumps should come with the power displayed (95% do) as its a great help in trouble shooting and would also have hepled in your case, IMO.

If you have the inclination/time you might do that pump test sometime, if only for interest, all these pumps should come with the power displayed (95% do) as its a great help in trouble shooting and would also have hepled in your case, IMO.

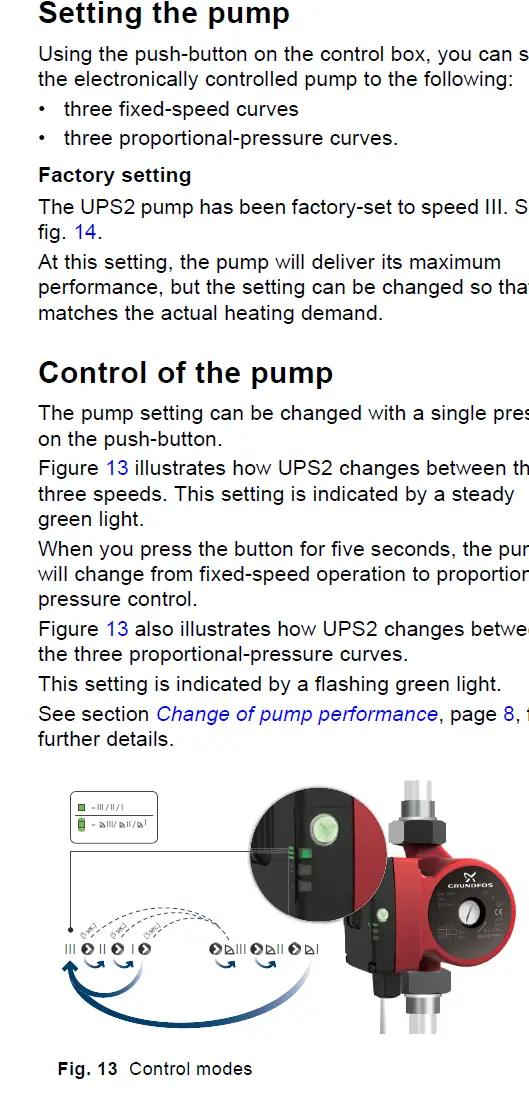

Thought I'd come back to this forum as this is where it originated. I don't know of any model of UPS2 that doesn't have proportional pressure (PP) mode, its pretty useless any way as far too low but could account for those low readings, You should get 22 watts reading on your setting of speed 2 even with the pump discharge valve closed, it is strange that the EM reads OK on other items but not apparently on your pump. I have used my monitor on numerous Grundfos pumps and all read exactly as per pump curves.

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

OK after a couple of days away I started again with a clear head and this time got sensible results.

I switched off the boiler, connected the pump to a separate supply and operated the zone valves manually. The results were the same whether HW or CH was selected:

I - 29W

II - 43W

III - 56W

PPI - 9W

PPII - 10W

PPII - 11W

Mike

I switched off the boiler, connected the pump to a separate supply and operated the zone valves manually. The results were the same whether HW or CH was selected:

I - 29W

II - 43W

III - 56W

PPI - 9W

PPII - 10W

PPII - 11W

Mike

The PP curves seem pretty accurate but can't make sense of the speed curves as the max pump powers are 23W, 37W & 47W for speeds I,II&III and you are reading 29W, 43W & 56W.

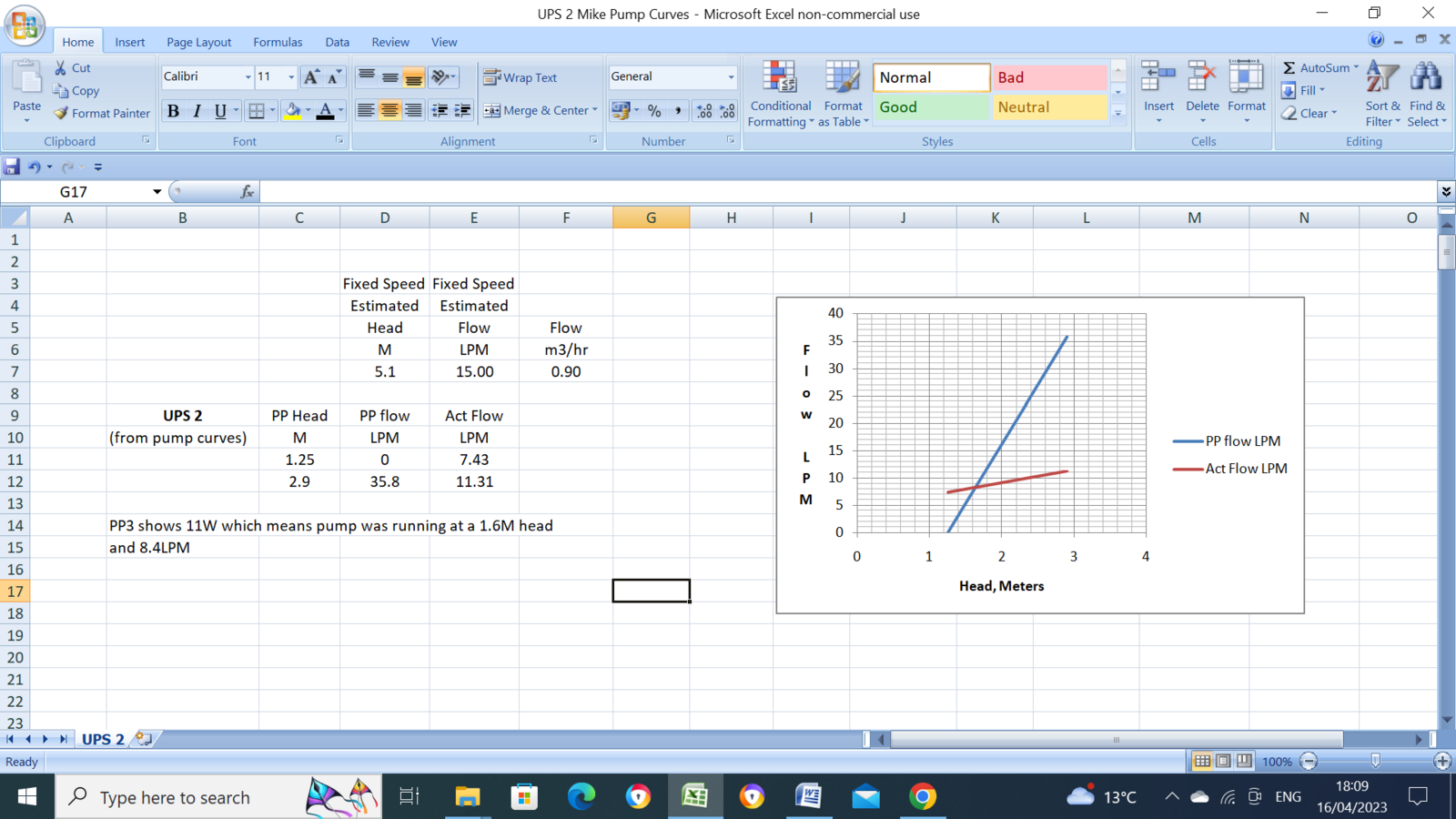

So based on a PP3 setting and 11W equates to a head of 1.6M @ 8.4LPM (0.5m3/hr), this would equate to a 5.1M head @ 15.0LPM, (0.9m3/hr),in turn this maps fairly close to running at speed 3 but power would be 46W, so best guessestimate is that the pump on speed 2 is pumping ~ 13LPM to15LPM @ a 4.6M to 5.1M head.

So based on a PP3 setting and 11W equates to a head of 1.6M @ 8.4LPM (0.5m3/hr), this would equate to a 5.1M head @ 15.0LPM, (0.9m3/hr),in turn this maps fairly close to running at speed 3 but power would be 46W, so best guessestimate is that the pump on speed 2 is pumping ~ 13LPM to15LPM @ a 4.6M to 5.1M head.

I should have asked you to run the tests as well with the pump discharge valve shut on those 3 fixed speed settings, you might try that sometime.

Is the burner still cutting out with the same symptoms, ie the requested flow temp falling off to zero with consequent recycling?, if so is it possible to change the OT requested flow temperature to simple target flow temperature for a few days?

Also run test with pump discharge valve opened but all zone valves shut, then on say speed 2 only, if power hasn't increased from closed valve power, slowly reduce the ABV index until the power increases, at least this might give some indication of what head the pump is operating at, on speed 2.

Is the burner still cutting out with the same symptoms, ie the requested flow temp falling off to zero with consequent recycling?, if so is it possible to change the OT requested flow temperature to simple target flow temperature for a few days?

Also run test with pump discharge valve opened but all zone valves shut, then on say speed 2 only, if power hasn't increased from closed valve power, slowly reduce the ABV index until the power increases, at least this might give some indication of what head the pump is operating at, on speed 2.

Last edited:

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

Sorry but what is a pump discharge valve? Do you mean the gate valves either side that shut off supply when removing the pump?I should have asked you to run the tests as well with the pump discharge valve shut on those 3 fixed speed settings, you might try that sometime.

Is the burner still cutting out with the same symptoms, ie the requested flow temp falling off to zero with consequent recycling?, if so is it possible to change the OT requested flow temperature to simple target flow temperature for a few days?

Also run test with pump discharge valve opened but all zone valves shut, then on say speed 2 only, if power hasn't increased from closed valve power, slowly reduce the ABV index until the power increases, at least this might give some indication of what head the pump is operating at, on speed 2.

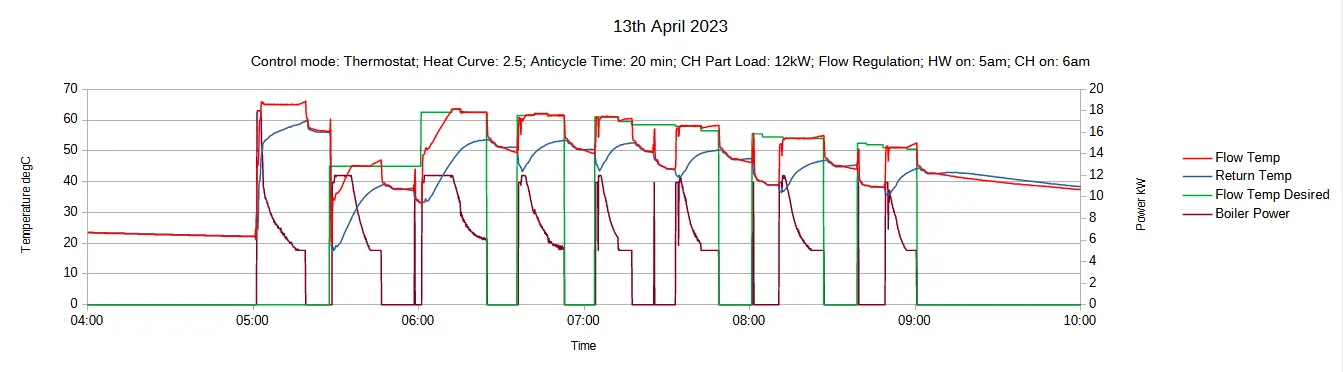

On the graph above (13th April) the OT was 6C and the heat curve was 2.5, giving a desired flow temp of around 60C. Under these conditions the desired flow temp dropped to zero periodically causing the burner to cut out.

This afternoon the OT was 15C and I'd lowered the heat curve to 1.5, giving a desired flow temp of around 30C. However, the minimum desired flow temp is set to 45C which overrides the heat curve, and in this case the desired flow temp didn't drop to zero but the burner still cuts out and the microfiring has returned:

BTW the controller is still in Thermostat mode.

Mike

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 8

- Views

- 6K

- Replies

- 11

- Views

- 3K

- Replies

- 1

- Views

- 1K