You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vaillant ecoTEC not reaching desired flow temperature

- Thread starter Yikes

- Start date

Mike,

Word of caution re shutting the pump isolating discharge valve, if its like the one shown, do NOT shut it as its more than likely that it will leak, if it has a spindle with a square on it where you can open/close it with a adjustable spanner or such, then OK.

But still run test with pump discharge valve opened but all zone valves shut, then on say speed 2 & 3 slowly increase the ABV index until the power decreases to its minimum, then increase it again until the power just starts rising, at least this might give some indication of what head the pump is actually running at.

Word of caution re shutting the pump isolating discharge valve, if its like the one shown, do NOT shut it as its more than likely that it will leak, if it has a spindle with a square on it where you can open/close it with a adjustable spanner or such, then OK.

But still run test with pump discharge valve opened but all zone valves shut, then on say speed 2 & 3 slowly increase the ABV index until the power decreases to its minimum, then increase it again until the power just starts rising, at least this might give some indication of what head the pump is actually running at.

Attachments

Last edited:

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

The gate valve has a square spindle. Is it really OK to run the pump with its output completely blocked?Mike,

Word of caution re shutting the pump isolating discharge valve, if its like the one shown, do NOT shut it as its more than likely that it will leak, if it has a spindle with a square on it where you can open/close it with a adjustable spanner or such, then OK.

Sadly I've run out of time to do this as we're going away shortly and the other jobs are piling up. I may just give up on weather compensation altogether and put the old (VRT 392f) controller back, at least until next winter.But still run test with pump discharge valve opened but all zone valves shut, then on say speed 2 & 3 slowly increase the ABV index until the power decreases to its minimum, then increase it again until the power just starts rising, at least this might give some indication of what head the pump is actually running at.

Mike

Its no problem to run the pump (dead headed) with the discharge isol va;lve closed for at least 10 minutes, (very) eventually the pump just might heat up to seal damaging degrees but I would doubt that even. My Wilo will heat up by ~ 0.7C/minute when dead heading at 4.8M.

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

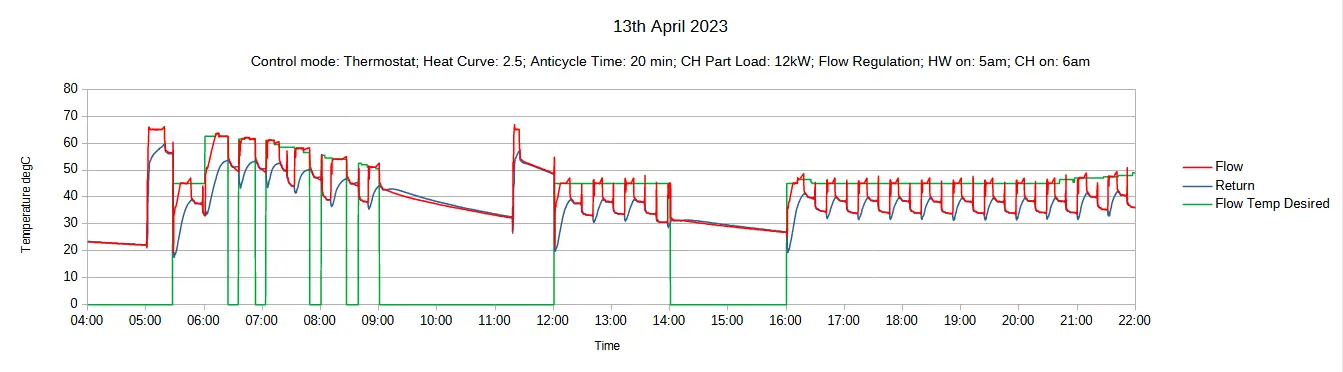

As I've decided to stop playing with this for a while I thought it would be a good time to summarise my experience with the Vaillant VRC 470f weather compensating controller. This graph best illustrates the problems I've been having:

My observations:

1) The HW cycle works just fine. The flow temperature reaches the set value of 65C and the boiler stays alight until the (wired) cylinder thermostat is satisfied.

2) The CH behaviour is bonkers. The heat curve I chose is typical for a 50 year old house in the UK. The resulting desired flow temperature in the morning started at 62C and dropped gradually, but for some reason it fell to zero several times and the burner cut off. In the afternoon the desired flow temperature was lower and did not fall to zero but the boiler still cut off anyway. There is also some microfiring.

3) I removed the wireless receiver from the boiler so there is no communication with the controller and set the flow temperature manually to 65C. Because the room thermostat bridge (pins 3 and 4) is closed the boiler ran continuously for several hours with an initial power of 12kW (the value of d.0) followed by 5kW (the boiler's minimum power). I think this proves that the boiler, pump and heating circuit are all working correctly.

My conclusion is that the VRC 470f wireless controller is not working as it should. I don't think it's a problem with communication because the signal strength is 7/10 and the manual states that anything above 3 is OK. Also the behaviour is too regular to be caused by an intermittent wireless connection.

I may send this to Vaillant tech support for their comments but doubt I'll get a sensible response.

I've now gone back to the previous Vaillant wireless controller to see if that is any better.

Mike

My observations:

1) The HW cycle works just fine. The flow temperature reaches the set value of 65C and the boiler stays alight until the (wired) cylinder thermostat is satisfied.

2) The CH behaviour is bonkers. The heat curve I chose is typical for a 50 year old house in the UK. The resulting desired flow temperature in the morning started at 62C and dropped gradually, but for some reason it fell to zero several times and the burner cut off. In the afternoon the desired flow temperature was lower and did not fall to zero but the boiler still cut off anyway. There is also some microfiring.

3) I removed the wireless receiver from the boiler so there is no communication with the controller and set the flow temperature manually to 65C. Because the room thermostat bridge (pins 3 and 4) is closed the boiler ran continuously for several hours with an initial power of 12kW (the value of d.0) followed by 5kW (the boiler's minimum power). I think this proves that the boiler, pump and heating circuit are all working correctly.

My conclusion is that the VRC 470f wireless controller is not working as it should. I don't think it's a problem with communication because the signal strength is 7/10 and the manual states that anything above 3 is OK. Also the behaviour is too regular to be caused by an intermittent wireless connection.

I may send this to Vaillant tech support for their comments but doubt I'll get a sensible response.

I've now gone back to the previous Vaillant wireless controller to see if that is any better.

Mike

The next time its running at 5kw you might note the flow/return temps, (you may have noted them allreready anyway) the flowrate can then easily be derived. the flowrate is quite important when the boiler is refiring and more so if OT control is used, some of the curves look for flow temperatures as low as 35C at 12C ambient, the return temp cant be much lower than say 25C no matter how long the anticycle time so requires a flowrate of ~ 15.5LPM at ignition conditions to avid exceeding 35C or 10.3LPM to avoid burner trip at 40C on refiring. It would be interesting to see what happens if you now lower the target temperature to 40C to see if the oiler fires up OK and runs normally at least for a reasonable period of time until or if the heat demand is lower than 5kw and the boiler goes to recycle when the flow temperature reaches 45C. The anticycle time will now be 13 minutes though.

OK then, if the boiler fires up at 60% output,10.8kw, then the dT is, 10.8*860/60/9.2, 16.8C, at a target temp of 65C the return has to be 48.2C or less to avoid exceeding 65C, or 53.2C to avoid burner trip at 70C, on OT control the requested target temp was ~ 48C so the return temps would have had to be 31.2C to avoid exceeding 48C or 36.2C to avoid burner trip at 53C.

The flow rate of 9.2LPM is interesting in that its reasonably close to the pump flowrate of 8.4LPM based on the PP3 curve and 11W but then the fixed speed settings make absolutely no sense, if you change from fixed speed 2 to fixed speed 3 then the ABV, at 3.5M,should be red hot and passing quite a lot of water so don't really know where you go from here apart from as suggested reducing the target temp to give better boiler efficiency.

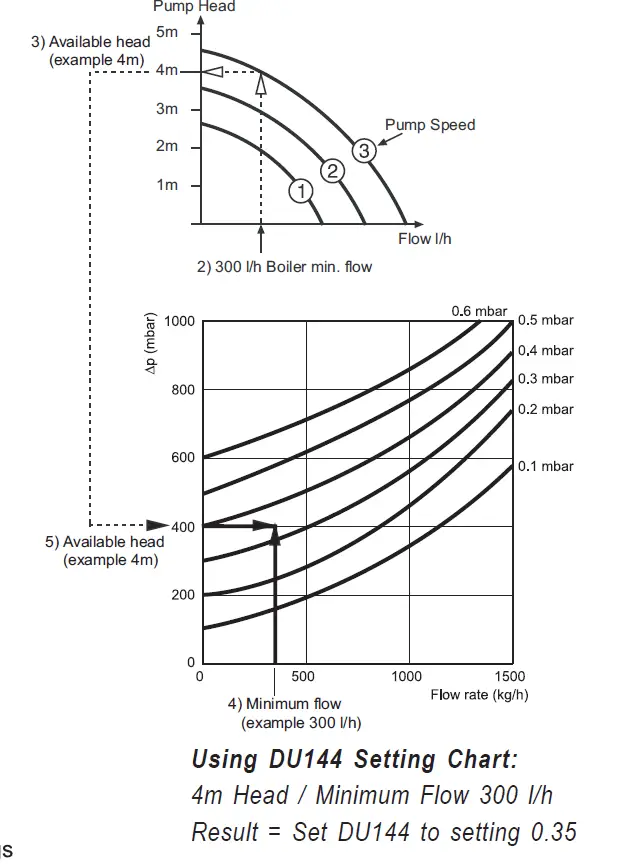

Example of typical ABV capacity below.

The flow rate of 9.2LPM is interesting in that its reasonably close to the pump flowrate of 8.4LPM based on the PP3 curve and 11W but then the fixed speed settings make absolutely no sense, if you change from fixed speed 2 to fixed speed 3 then the ABV, at 3.5M,should be red hot and passing quite a lot of water so don't really know where you go from here apart from as suggested reducing the target temp to give better boiler efficiency.

Example of typical ABV capacity below.

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

Thanks for explaining that, although as a humble electronics engineer I'm afraid hydraulics is not in my comfort zone ...

Regarding the controller's behaviour I'm not the only person who has had this problem. If you look at the first graph on this page you will see the same thing happening:

https://vaillantcyclingproblem.blogspot.com/p/problem.html

I will try Vaillant tech support and let you know what they say.

Mike

Regarding the controller's behaviour I'm not the only person who has had this problem. If you look at the first graph on this page you will see the same thing happening:

https://vaillantcyclingproblem.blogspot.com/p/problem.html

I will try Vaillant tech support and let you know what they say.

Mike

The heat curve I chose is typical for a 50 year old house in the UK.

I think, from memory - that the heat curve will gradually modify it's value, and do so constantly.

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

Not with this controller, that's a feature of the newer ones.I think, from memory - that the heat curve will gradually modify it's value, and do so constantly.

Mike

- Joined

- 23 Feb 2023

- Messages

- 56

- Reaction score

- 3

- Country

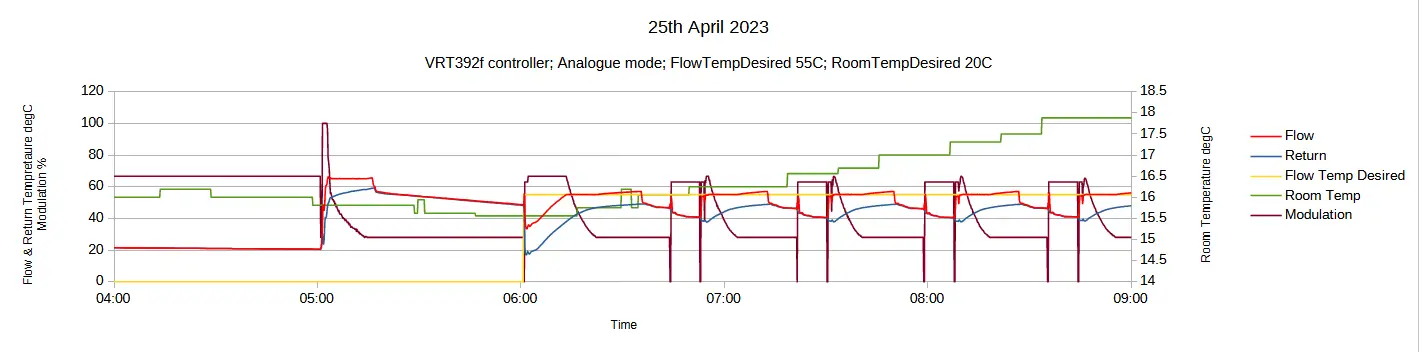

Hi John, I'm back again

I replaced the VRC470f weather controller with the VRT392f room thermostat. Here it is running in Analogue mode:

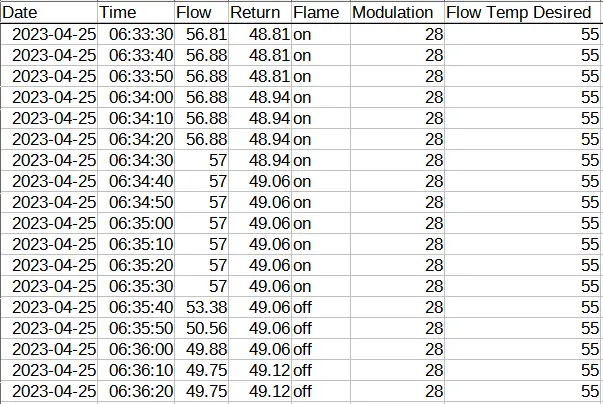

You can see the Flow temperature starting to rise as soon as the Modulation drops to 28%, and when it exceeds FlowTempDesired by exactly 2 degrees the burner shuts down:

Any ideas what might cause this temperature rise? Incidentally exactly the same thing happens with the weather controller.

Mike

I replaced the VRC470f weather controller with the VRT392f room thermostat. Here it is running in Analogue mode:

You can see the Flow temperature starting to rise as soon as the Modulation drops to 28%, and when it exceeds FlowTempDesired by exactly 2 degrees the burner shuts down:

Any ideas what might cause this temperature rise? Incidentally exactly the same thing happens with the weather controller.

Mike

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 8

- Views

- 6K

- Replies

- 11

- Views

- 3K

- Replies

- 1

- Views

- 1K