Agh why,

I have changed a few RADS and most times they are fine, but reading a lot some folk say leave the threads alone where others say wrap PTFE tape around the threads. I've done both ways and I still get a very small leak?

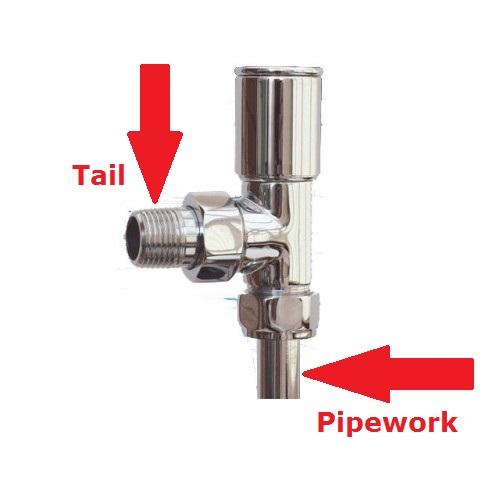

I know you always PTFE the tails but the valve threads themselves...not usually as they should be sufficient on their own.

Help!

What am I doing wrong, I hand tighten the bolts then a half turn, check and another half turn if needed, did all this and still a leak...water?? is there a better way these days...

I have changed a few RADS and most times they are fine, but reading a lot some folk say leave the threads alone where others say wrap PTFE tape around the threads. I've done both ways and I still get a very small leak?

I know you always PTFE the tails but the valve threads themselves...not usually as they should be sufficient on their own.

Help!

What am I doing wrong, I hand tighten the bolts then a half turn, check and another half turn if needed, did all this and still a leak...water?? is there a better way these days...