Hi Everyone

I think I have just wasted a few days changing my Central Heating pipework. From what I have read on the Forum I think I have introduced Reverse Flow !!!. Can anyone confirm what changes I now have to make it work correctly.

Now my central heating only works when two or three zones are open at once. If just one zone valve is open the Vaillant Ecotec 438 boiler shuts down after a short while indicating code S.53 - Appliance is within the waiting period of the operation block function due to water shortage (VL-RL spread too big)

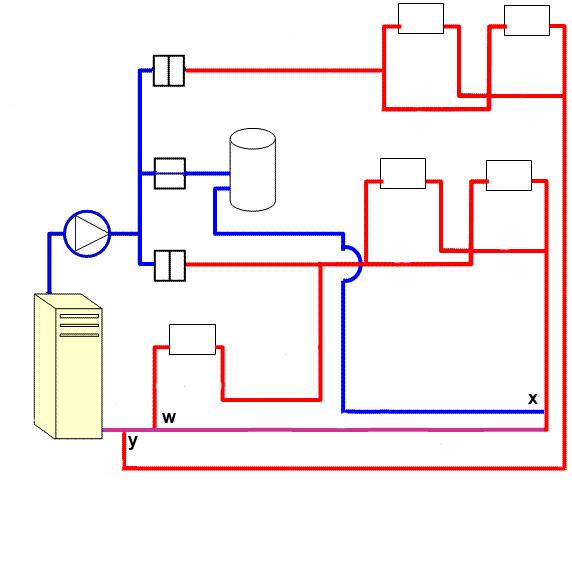

I have attached a schematic of my system (thanks to ChrisR - I changed his original picture)

I have introduced an extra zone (house extension) and connected the return as the last 'T' connection before the boiler (Y) which seems to have messed things up. Previous forum posts I've now read say it should be HW connection last.

However the existing HW return has a 'T' connection directly with the old CH Return (X) and there is even a single radiator 15mm 'T' as the last connection into the 22mm return (W) but it still worked ok.

How come it works with two valves open but not one. Can one of you helpful experts confirm what changes I now have to make so that it works correctly again.

Cheers

I think I have just wasted a few days changing my Central Heating pipework. From what I have read on the Forum I think I have introduced Reverse Flow !!!. Can anyone confirm what changes I now have to make it work correctly.

Now my central heating only works when two or three zones are open at once. If just one zone valve is open the Vaillant Ecotec 438 boiler shuts down after a short while indicating code S.53 - Appliance is within the waiting period of the operation block function due to water shortage (VL-RL spread too big)

I have attached a schematic of my system (thanks to ChrisR - I changed his original picture)

I have introduced an extra zone (house extension) and connected the return as the last 'T' connection before the boiler (Y) which seems to have messed things up. Previous forum posts I've now read say it should be HW connection last.

However the existing HW return has a 'T' connection directly with the old CH Return (X) and there is even a single radiator 15mm 'T' as the last connection into the 22mm return (W) but it still worked ok.

How come it works with two valves open but not one. Can one of you helpful experts confirm what changes I now have to make so that it works correctly again.

Cheers