That's not strictly true...But if you don't ask you'll never know

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding socket needed for 17th edition board?

- Thread starter Ruggers

- Start date

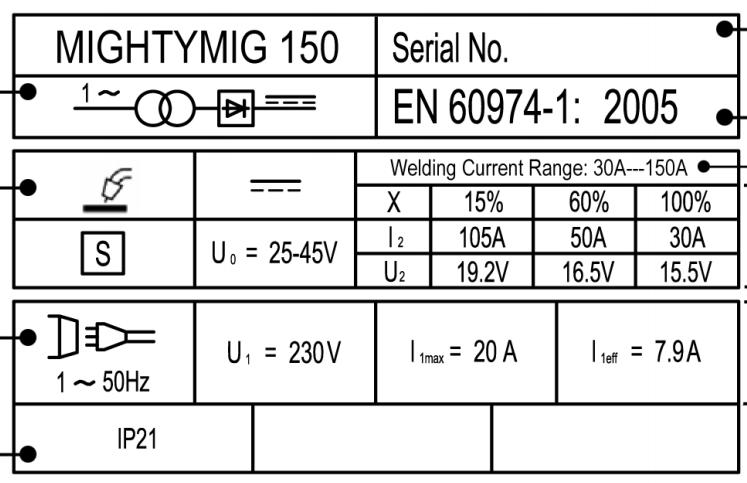

So does that mean it needs a 20A supply?Power Input: 230V - 1ph

Absorbed Power: 4.5kW

The instruction manual show it fitted with a 13A plug http://www.tooled-up.com/artwork/ProdPDF/MIGHTYMIG150.pdf Apparently it has a "Maximum effective current" (whatever that is) of 7.9A

MIG welders typically operate at a fixed voltage of around 30VDC so that's (roughly) where the 4.5KW comes from on that "150A" welder.

And yes, that would suggest that at full tilt, the 150A welder will need just shy of 20A at 230V. It's interesting to see, as an aside, that the duty circle mentioned in the specs, earlier, at 105A (is that a typo - should it read "150A"?) is only 15%. So at full tilt, you'll spend most time waiting for the kettle to boil...

There's normally a much higher inrush on first startup, so the received wisdom in welding circles is to run it off a dedicated C-type MCB; my 150A MIG is on a C32 (with SWA and circuit design done, installed, tested and certified by the electrician, before b-a-s jumps in )

)

John's point is correct - I asked on my favourite welding forum and the majority of people had never heard that permission should be sought.

And yes, that would suggest that at full tilt, the 150A welder will need just shy of 20A at 230V. It's interesting to see, as an aside, that the duty circle mentioned in the specs, earlier, at 105A (is that a typo - should it read "150A"?) is only 15%. So at full tilt, you'll spend most time waiting for the kettle to boil...

There's normally a much higher inrush on first startup, so the received wisdom in welding circles is to run it off a dedicated C-type MCB; my 150A MIG is on a C32 (with SWA and circuit design done, installed, tested and certified by the electrician, before b-a-s jumps in

John's point is correct - I asked on my favourite welding forum and the majority of people had never heard that permission should be sought.

So does that mean it needs a 20A supply?Power Input: 230V - 1ph

Absorbed Power: 4.5kW

The instruction manual show it fitted with a 13A plug http://www.tooled-up.com/artwork/ProdPDF/MIGHTYMIG150.pdf Apparently it has a "Maximum effective current" (whatever that is) of 7.9A

Unfortunately, most single phase MIGs are sold with a 13A plug, but the figures don't lie; 4.5KW is almost 20A at 230V.

Having said that, given the poor duty cycle (as mentioned above) at 150A DC / 20A AC, chances are a 13A fuse or 16A MCB may not trip.

I don't like it, though, and personally believe that any welder over 90A (DC, aka ~12A AC) should be on a 16A commando plug.

The instruction manual show it fitted with a 13A plug http://www.tooled-up.com/artwork/ProdPDF/MIGHTYMIG150.pdf Apparently it has a "Maximum effective current" (whatever that is) of 7.9A

It has a maximum input current of 20A @ 230V AC, and is most efficient (unsurprisingly) at the much lower input current of 7.9A @ 230V AC, which equates to it's 100% duty cycle of 30A (DC output current). Good for welding car panels

I have a 16A interlocked socket in my garage for such a future purpose.

Note the word 'interlocked'. By rights/regs all sockets in domestic premises should have shutters however with commando sockets that's just not practicable. So the likes of GeWiss sell a socket with interlocked on/off switch which can't be on unless a socket is inserted. I believe this provides sufficient equivalence of the requirements.

Note the word 'interlocked'. By rights/regs all sockets in domestic premises should have shutters however with commando sockets that's just not practicable. So the likes of GeWiss sell a socket with interlocked on/off switch which can't be on unless a socket is inserted. I believe this provides sufficient equivalence of the requirements.

No.By rights/regs all sockets in domestic premises should have shutters

1) BS EN 60309-2 is the standard required for 16, 32, 63 & 125A sockets.

2) It's sockets for household and similar use which are required to be shuttered.

That said, the interlocked ones are a jolly good idea.

Of the 3 "150A" (actually 2 @ 150A and 1 @ 145A) MIG welders that Toolstation sell, that one is the cheapest, lightest, worst duty cycle, lowest power consumption one.MIG welders typically operate at a fixed voltage of around 30VDC so that's (roughly) where the 4.5KW comes from on that "150A" welder.

And yes, that would suggest that at full tilt, the 150A welder will need just shy of 20A at 230V. It's interesting to see, as an aside, that the duty circle mentioned in the specs, earlier, at 105A (is that a typo - should it read "150A"?) is only 15%. So at full tilt, you'll spend most time waiting for the kettle to boil...

I wonder if it's built down to a spec to appeal to people who simply wouldn't buy it if it didn't have a 13A plug?

The manuals for both Sealey ones quote duty cycles at 105A, nothing higher, so I doubt it's a misprint. The manual for the other "150A" Sealey does say

IMPORTANT! If using welder to full

capacity, we recommend a 16amp

supply. We recommend you discuss

the installation of a 16amp industrial

round pin plug and socket with your

electrician.

Of the 3 "150A" (actually 2 @ 150A and 1 @ 145A) MIG welders that Toolstation sell, that one is the cheapest, lightest, worst duty cycle, lowest power consumption one.MIG welders typically operate at a fixed voltage of around 30VDC so that's (roughly) where the 4.5KW comes from on that "150A" welder.

And yes, that would suggest that at full tilt, the 150A welder will need just shy of 20A at 230V. It's interesting to see, as an aside, that the duty circle mentioned in the specs, earlier, at 105A (is that a typo - should it read "150A"?) is only 15%. So at full tilt, you'll spend most time waiting for the kettle to boil...

I wonder if it's built down to a spec to appeal to people who simply wouldn't buy it if it didn't have a 13A plug?

The manuals for both Sealey ones quote duty cycles at 105A, nothing higher, so I doubt it's a misprint. The manual for the other "150A" Sealey does say

IMPORTANT! If using welder to full

capacity, we recommend a 16amp

supply. We recommend you discuss

the installation of a 16amp industrial

round pin plug and socket with your

electrician.

If it's not a misprint, then that's appalling. Any 150A MIG needs a dirty great fan on it to keep it cool and get a decent duty cycle.

To be honest, speaking as a hobbyist welder, 50-60% at 150A would be good enough for me, giving the clamping and tacking required, but 30% way down at 105A is awful.

I think your point about being built to a spec is correct. Being in a little box (hence poor airflow and either no or a tiny fan) and having a 13A plug, makes them seem that anyone can pick them up and start welding, which is unrealistic.

You need a lot of practice to weld well, even to tell whether what you just welded (which may look strong) has decent enough penetration.

In reality, a decent sized welder with a decent sized fan, on a properly specced AC plug is required. Did I mention Aldi selling a 90A Arc Welder for £30?

I suspect that what you mean is that any 150A MIG welder made for a price that a hobbyist could justify needs such a fan.Any 150A MIG needs a dirty great fan on it to keep it cool and get a decent duty cycle.

You can get water cooled ones. Possibly oil too?

I suspect that what you mean is that any 150A MIG welder made for a price that a hobbyist could justify needs such a fan.Any 150A MIG needs a dirty great fan on it to keep it cool and get a decent duty cycle.

You can get water cooled ones. Possibly oil too?

Nope, not really. Yes, you can get oil-cooled welders (water-cooled much less so). Oil-cooling does tend to be more prevalent in arc-welders, rather than MIG, though.

But we're conflating two different arguments, here. MIG welders will be air-cooled all the way up to the £2k / £3k and beyond, and most professional MIG and TIG welders will be air-cooled (qualification; with a fan, rather than just ambient air).

My argument, which I'm sure you agree with despite your tendency to disagree, is that any welder from 90A upwards should have a fan, otherwise their duty cycle renders them pretty impractical. I would go further and suggest that the drive toward a "bench-sized" welder is counter to the requirement to encourage good airflow, and I'd expect any MIG welder above 90A to be of the "pull-along" size so that the fan can be large enough and there is enough space to push the air across the transformer and choke. Forget "amateur" or "professional", but above 90A you need to keep the electrics cool, and you can do this with a thermal cutout (low duty-cycle) or with a fan (high[er] duty-cycle).

Don't be distracted by thoughts of oil or (less likely) water cooling - getting decent airflow in a MIG welder is 90% of the battle.

That makes sense. I don't know, but would have suspected, that even if one did have oil (or water) cooling, one would probably still need a fan. Isn't that the case?Don't be distracted by thoughts of oil or (less likely) water cooling - getting decent airflow in a MIG welder is 90% of the battle.

Kind Regards, John

So is this a poor mig welder for all that understand the technical spec?

I want to weld 5mm angle and 3mm box mild steel, it was rated as one of the better ones ona mig welding forum i asked about 12 months ago for under £250

I want to weld 5mm angle and 3mm box mild steel, it was rated as one of the better ones ona mig welding forum i asked about 12 months ago for under £250

So is this a poor mig welder for all that understand the technical spec?

I want to weld 5mm angle and 3mm box mild steel, it was rated as one of the better ones ona mig welding forum i asked about 12 months ago for under £250

Jeez Dan - sorry, mate - we forgot you were there

Nah - you're good. At this end, Sealey, Clarke, etc are all pretty decent.

5mm is right at the limit of what a 150A MIG can cope with but, with a bit of careful filleting, you would be able to do it. If you really are going to be doing a lot of 5mm welding then a 210A unit may be more suitable.

If most of your welding is going to be at that end then you should really look at a dedicated 16A or 32A feed for it.

At that price, too, have a look on ebay / classifieds for a used 210A unit, but you will definitely need to evaluate the supply to it.

((I'm going to consciously not comment on Westie's advice re notifying the DNO))

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local