Hi I’m in the process of building an orangery on the back of our house which will have an outer pitched roof with a flat top which will then have a glass lantern on top.

I’m hoping someone will be able to point me in the right direction and answer a few questions about the roof makeup, insulation and ventilation. I’ve already had a steep learning curve with regards to foundations, soak ways etc so now it’s time for the beginning of lessons in roofing.

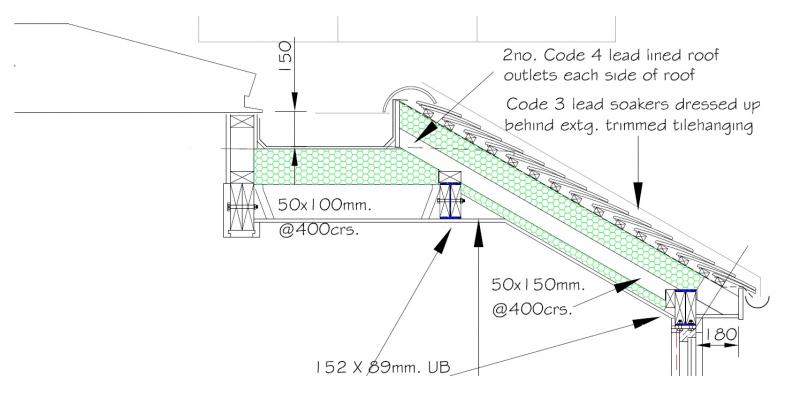

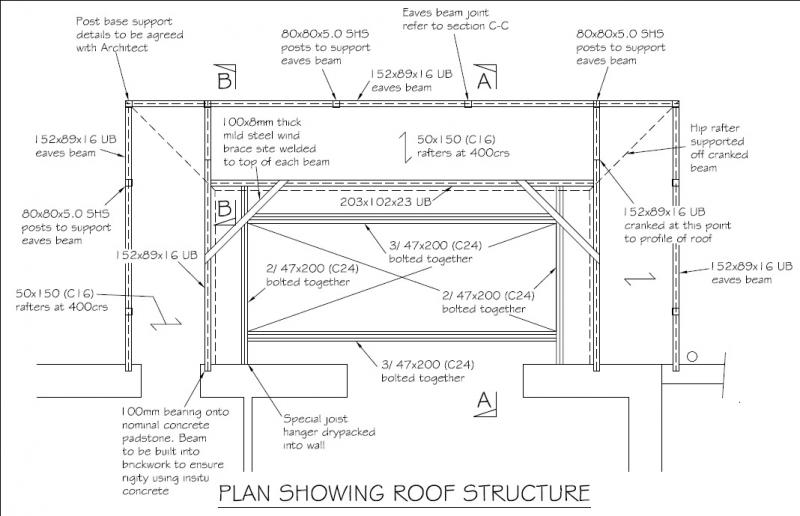

For the pitched section of roof the architect has specified a unventilated makeup of concrete plain tiles on 25 x 38mm preservative treated s.wood battens on proprietary microporous sarking membrane (avoiding need for ventilation), on 47 x 150mm C16 rafters at max 400mm crs. 80mm Celotex GA4080 between rafters, overlaid with vapour control layer and 45mm Celotex PL4000 at ceiling height to give a U-value of 0.18W/m²K.

However looking at the Celotex website it seems for an unventilated roof it suggests I would need to use Celotex XR4120 between rafters and Pl4000 in 25mm depth under the rafters.

I would like to keep the ceiling height below the rafters as high as possible and the height of the tiles as low as possible so it looks like the Celotex suggestion looks the better option but are there other pros and cons to each build up? I’m also a little confused as it looks like I will have a 30mm gap above the celotex to the top of the rafter, as it’s meant to be unventilated do I need this gap and would I need to counter batten above the rafters? Is there an option to full fill to the depth of the rafter with no insulation below? Maybe I should mention at this point I would like to opt for exposed rafter tails if possible so I’m very unsure of what I need to provide in the way of ventilation and where it should be.

Now onto the flat roof section.

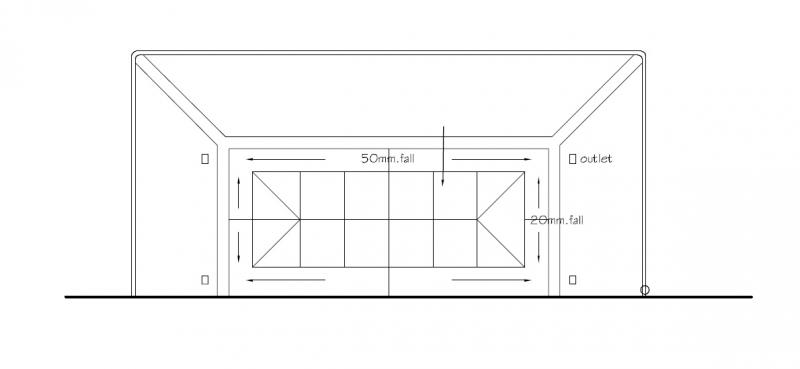

The architect has specified a flat roof (warm construction) to comprise 13mm thickness of white spar chippings on 3-layer built-up felt roofing (or proprietary high performance roofing system), on 126mm CelotexTD4126 insulated decking with integral vapour barrier. Felt dressed up beneath existing tile hanging at rear and perimeter of rectangular lantern light. Decking to be secured through s.w. firings, (1 in 40 fall ) into 47 x100mm C16 roof joists at 400mm crs. Roof void to be unventilated and to be provided with ceiling of 12.5mm. “Duplex” plasterboard or standard plasterboard with polythene vapour barrier. Vapour barrier to be sealed at joints and perimeter. Roof to fall to 4no code 4 lead-lined outlets discharging over lead apron to gutter below tiled roof.

As you can see from the diagram the flat roof section will also act as the gutter/drain for the lantern so would it be better to use epdm or felt to cover the roof, I would need access for maintenance and cleaning from time to time? I’m also wondering about the firings to give the slope to the sides along with the front and back at the same time, is there a better way to do this? And is the Celotex ok just sitting on the firings or would I need a further layer of ply/osb?

All ideas and suggestions welcome.

Many thanks.