I have a 1930's extension on our house which was originally built as a small scale dairy, and more recently used as a workshop. I want to make it a bit more of a useable room as currently there are a number of problems with it - it is solid wall of only 6 inch, no heating, damp, condensation/mould over the walls, leaking roof, the concrete floor is knackered and big old wooden doors falling to pieces letting a draft in.

I am planning on renovating it and using it as a gym. The changes I plan to make include: blocking up the external doors, laying a new insulated concrete floor, batten, insulate and board walls and ceiling, new roof, extend central heating into the room and decorate.

Some pics below of progress to date:

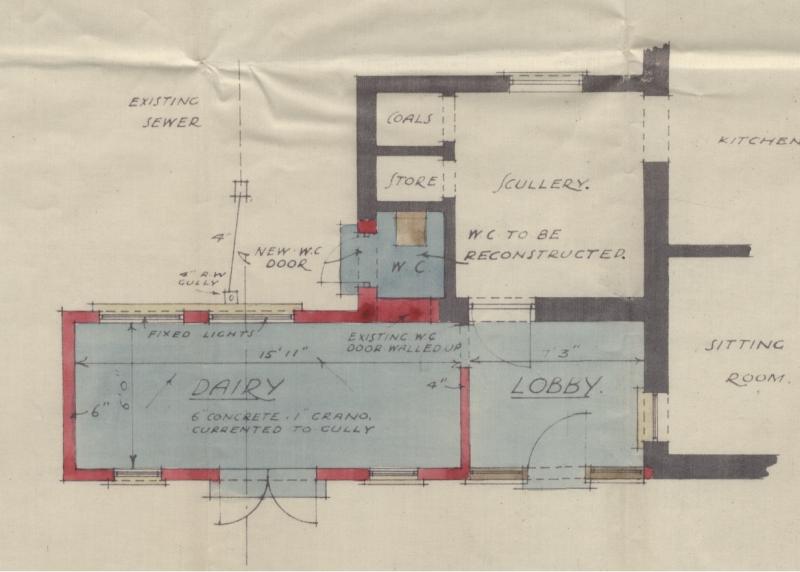

1930's plan of the extension

Workshop as it was when we moved in

The old doors

Workshop cleared out

Workshop from the outside

Old doors blocked up in Bathstone - I might try and age these artificially or try and jet wash the old stone to make the colours a bit more similar

Concrete floor taken up ready for a new floor

Will post updates when I've made more progress - next job is to lay the new concrete floor

I am planning on renovating it and using it as a gym. The changes I plan to make include: blocking up the external doors, laying a new insulated concrete floor, batten, insulate and board walls and ceiling, new roof, extend central heating into the room and decorate.

Some pics below of progress to date:

1930's plan of the extension

Workshop as it was when we moved in

The old doors

Workshop cleared out

Workshop from the outside

Old doors blocked up in Bathstone - I might try and age these artificially or try and jet wash the old stone to make the colours a bit more similar

Concrete floor taken up ready for a new floor

Will post updates when I've made more progress - next job is to lay the new concrete floor