Hi guys,

Im researching what route to go with for our heating system. Currently only the rads we are keeping are still in place, everything else is being replaced and we need to finalise this so it can be plumbed before getting insulation/screed done.

I like the idea and flexibility of a thermal store but im told they are only worth having if your using a stove/fire back boiler or heat pump?

We would like to utilise the back boiler on the fire but pipe work to the new tank location is difficult and unlikely to produce the required gravity circuit. Realistically this is only going to be used at weekends or a evening for a few hours so dont know if its worth considering.

Given the following setup and limitations would you say thermal store or unvented?

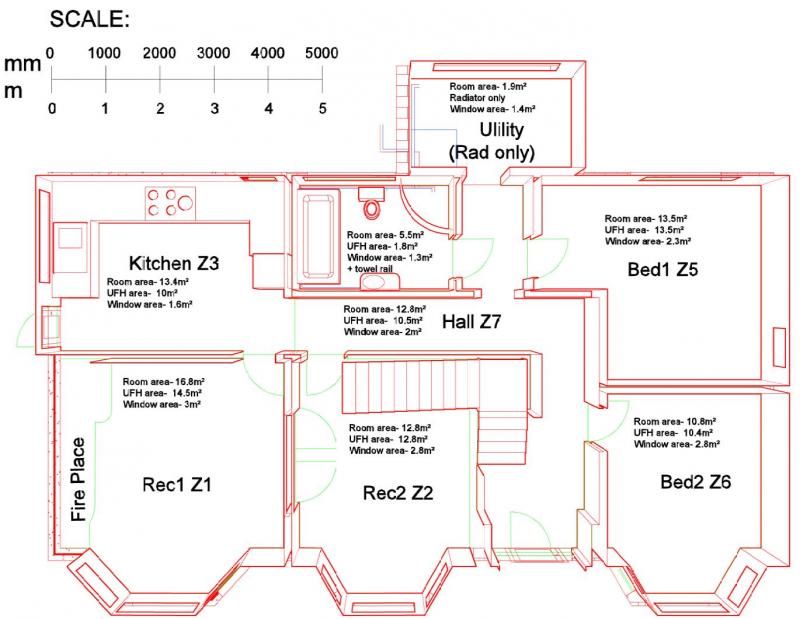

Tank to be located in ground floor (bungalow) utility room approx 2.3m high, have a space 900mmx1200mm for tank and pipework, valves and pumps to fit.

Fire is 9m straight line from tank, more likely 15m in pipework terms. top connection on back boiler is 700mm above the floor. This means i need a tank max height of 1500mm so it can be raised enough to get a gravity circuit (is this correct??)

Heat sources will be

Oil boiler

Solar panel

Back boiler on open fire (if we can keep it)

Heat emitters

90m² UFH - approx 650m of pipe

1 towel rail

4 rads (3 in loft conversion, 1 in conservatory)

Hot water for 2 adults (at present) main requirement mornings and evenings.

1 Bathroom with drench shower (unlikely for both bath and shower to be in use at same time), Kitchen sink, wash machine.

Given the above, ive been told to get a thermal store because they are great for UFH and i "Should" be able to get the back boiler working using a pump (i dont think this is good practice if the power goes out).

Other hand ive been told to go unvented as its more straight forward, takes up less space and has a faster recovery time, downsides are no back boiler and ongoing maintenance costs.

Cheers for any info

Im researching what route to go with for our heating system. Currently only the rads we are keeping are still in place, everything else is being replaced and we need to finalise this so it can be plumbed before getting insulation/screed done.

I like the idea and flexibility of a thermal store but im told they are only worth having if your using a stove/fire back boiler or heat pump?

We would like to utilise the back boiler on the fire but pipe work to the new tank location is difficult and unlikely to produce the required gravity circuit. Realistically this is only going to be used at weekends or a evening for a few hours so dont know if its worth considering.

Given the following setup and limitations would you say thermal store or unvented?

Tank to be located in ground floor (bungalow) utility room approx 2.3m high, have a space 900mmx1200mm for tank and pipework, valves and pumps to fit.

Fire is 9m straight line from tank, more likely 15m in pipework terms. top connection on back boiler is 700mm above the floor. This means i need a tank max height of 1500mm so it can be raised enough to get a gravity circuit (is this correct??)

Heat sources will be

Oil boiler

Solar panel

Back boiler on open fire (if we can keep it)

Heat emitters

90m² UFH - approx 650m of pipe

1 towel rail

4 rads (3 in loft conversion, 1 in conservatory)

Hot water for 2 adults (at present) main requirement mornings and evenings.

1 Bathroom with drench shower (unlikely for both bath and shower to be in use at same time), Kitchen sink, wash machine.

Given the above, ive been told to get a thermal store because they are great for UFH and i "Should" be able to get the back boiler working using a pump (i dont think this is good practice if the power goes out).

Other hand ive been told to go unvented as its more straight forward, takes up less space and has a faster recovery time, downsides are no back boiler and ongoing maintenance costs.

Cheers for any info