You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reverse convection flow in wood-burner

- Thread starter cbell

- Start date

I still say that you will not get hotter water going down and displacing colder water upwards by gravity alone. This isn't theory, it is indisputable, unchangeable, concrete fact.

Where has anyone stated this is happening?

I would think any DIYer with half a brain could soon work it out.

you stand corrected

You saying your a DIYer

A gravity Circuit can not reverse circulate through the return pipe

It is true that reverse circulation can occur whereas the hot water in the cylinder can indeed travel back down the flow pipe into the boiler, that was quite common and the reason for an anti gravity loop on the return.

A gravity Circuit can not reverse circulate through the return pipe

Isn't that what this thread is about?

It is true that reverse circulation can occur whereas the hot water in the cylinder can indeed travel back down the flow pipe into the boiler, that was quite common and the reason for an anti gravity loop on the return.

Which of these two statements did you mean to state? They are a tad contradictory.

Read the posts, think you'll realise im not a diy er

A gravity Circuit can not reverse circulate through the return pipe

Read the posts, the guy with the problem is no SFB.

Something weird is happening and he asked for options to cure it. Ive given him 3 so far and not just dismissed that what he clearly says is happening isnt or cant be happening.

A gravity Circuit can not reverse circulate through the return pipe

Read the posts, the guy with the problem is no SFB.

Something weird is happening and he asked for options to cure it. Ive given him 3 so far and not just dismissed that what he clearly says is happening isnt or cant be happening.

A gravity Circuit can not reverse circulate through the return pipe

Isn't that what this thread is about?

It is true that reverse circulation can occur whereas the hot water in the cylinder can indeed travel back down the flow pipe into the boiler, that was quite common and the reason for an anti gravity loop on the return.

Which of these two statements did you mean to state? They are a tad contradictory.

Not at all Oilman.

If the boiler is cold, under certain conditions the hot water in the cylinder can reverse back down the flow into the boiler, the heat in the store is heating the primary flow, It cannot reverse circulate down the return, because the flow of the coil would always be hottest, unless as a thought the flow has been connected in the bottom tapping.

What could also be happening, and giving the impression of a reverse circulation is.

As the boiler heats up the water will rise up the flow in the normal way, however the return from the cylinder will be heated by the store, so until equilibrium is reached the return will be hotter.

Read the posts, think you'll realise im not a diy er

A gravity Circuit can not reverse circulate through the return pipe

Read the posts, the guy with the problem is no SFB.

Something weird is happening and he asked for options to cure it. Ive given him 3 so far and not just dismissed that what he clearly says is happening isnt or cant be happening.

cider said:raise the flow from the gravity circuit above the heat store as high as possible (with an open vent over header tank) and then drop back down to the flow connection to the store.

That would help the reverse circulation from the store, back to the boiler vis the FLOW pipe.

cider said:OK then, how about fitting pump on a bypass with a reverse acting (motor closed) diverter valve. When the pump has to run (manually or via stat) the valve motor closes, end switch starts pump and circulation correceted

It's a gravity circuit, a pump is not needed unless there's a major design fault. A bodge in other words.

cider said:Can you divert the primary flow away from the heat store once its temp is satisfied therefore continuing gravity circulation from stove ?

28mm diverter valve on inlet to heatstore dropping back into return controlled via cyl stat.

This is my favorite, Divert it where, the storage tank in the loft perhaps.

I seem to have stirred up a bit of a hornet's nest here! Many responses ask for more detail, so here is some.

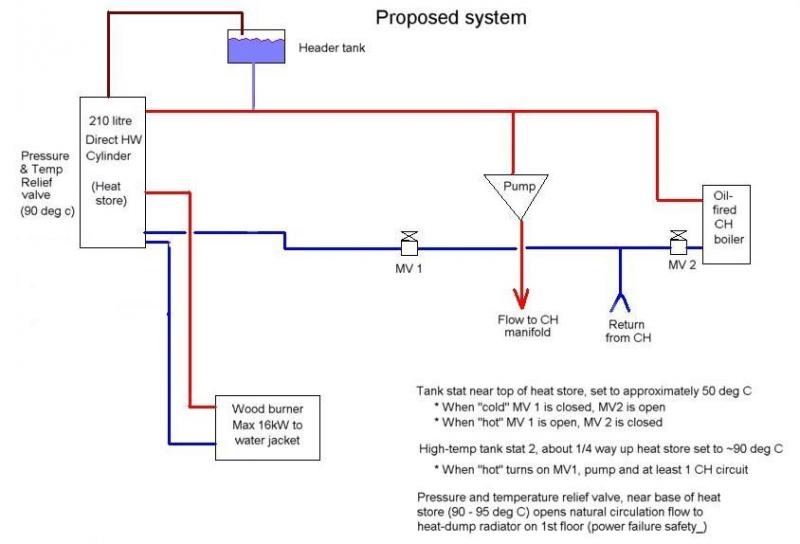

Firstly the system design. Here is the original schematic diagram which was how I designed it and, in fact, is pretty much how it got built. (Sorry about the size, I'm still using how to learn this forum software, but I think it enlarges if you click on it.)

To recap a little: the heat store is a bog standard 210 litre direct HW cylinder with 2x tappings 180 degrees apart at top and bottom (ie 4 holes in sides and one at top used as a vent here). The flow from (top of cylinder) and return to (bottom) are on one side, and the flow/return to CH system are likewise on the other. All pipework is 28mm.

You'll see from the diagram that there is no direct connection between CH system and stove, but rather that the stove heats the store by gravity convection (over a height of 2 floors), and the the CH system draws hot water from the store when it is available. The actual water and header tank are common, but I'd say it was next to impossible for the CH pump to induce any flow through the stove.

Now for the control system. I designed and built this myself, and I won't bore you with a circuit diagram, but I think a picture of the control panel may help:

The ideas behind this are:

+ Heating should be available on demand at any time, drawing from the heat store if it is hot, and from the oil-fired boiler if it is not.

+ Switchover between heat sources should be automatic, based on the output from a thermostat at the top of the tank. This is set to about 50 deg C, and when this temperature is reached the store is deemed to be "hot".

+ There is also safety circuitry so that when the heat store gets too hot, defined by a 2nd thermostat at its base reaching about 75 deg C, then an override switches on to pump water through the selected CH zone(s) regardless of the state of room stats, timers, etc.

+ The CH system in this house is fully pumped, with 5 zones: 1 being domestic hot water (through a separate indirect cylinder), and the other 4 being various areas of the house. All five zones have separate timer circuits and thermostats controlling their own motorised zone valves.

+ When adding the heat store and wood-burner we added two further motorised valves: one to the oil-fired boiler and one to the heat store. This was to apply positive control over where heat was drawn from, and also to stop heat from the store being pumped through a (cold) boiler, and vice-versa.

I hope you'll all note that there are currently no valves or pumps in the circuit between wood-burner and heat store. Circulation here is purely by gravity convection.

My theory that reverse convection is happening is based on the following evidence:

+ The return pipe from store to stove is significantly hotter than the flow from stove to store. This based both on the evidence of my hand when touching the pipes, and from the dual-channel digital thermometer I have attached to them.

+ If I blaze up the heat store in this state then the return pipe gets even hotter, the flow colder, and before long I get bumping noises from the boilers at the bottom of the stove.

This has only happened twice in 3 months of operation, but on both occasions it was when:

+ The stove had been loaded up in the mid-afternoon, heating the store.

+ At that time of day the CH system is not on, so the store simply heated up.

+ Once it ran out of fuel (after about 2 hours) the fire died right down, and the stove cooled down too.

+ I then refuelled the stove and blazed it up.

Watching the digital thermometer readout (in real-time) I could see the following happening:

(1) Flow temp (from stove to store) rose slightly, starting normal convection, in the range 40 - 50 deg C.

(2) Return temp (from store to stove) then rose sharply to about 70 deg C as - my assumption - hotter water was drawn down from the store.

(3) This effectively stopped and - my assumption again - slightly reversed normal convection flow.

(4) Yet another assumption: this reversal drew hot water from the stove's boilers back up the return pipe, reinforcing the reverse flow. I could see the return temperature rise and the flow fall as this occurred.

(5) Obviously this flow was poor, since it was working against nature, gravity, the thermal gradient in the system (and everything else!) so heat could not escape properly from the stove, at which point water started bumping away as it boiled.

So my original question was "how could I add a pump to the gravity system in order to restore the correct flow direction?". I would want this to be normally off and to switch on in two circumstances:

(1) When the outlet temperature of the stove exceeds about 70 deg C, as experience shows that it is capable when run flat out of raising the water temperature across itself by 30+ deg C under normal gravity flow, causing boiling, therefore increasing the water flow rate would extract heat more quickly and prevent this.

(2) To restore the correct flow direction when the reverse convection I've described above occurs. This would be switched manually, although in fact putting a thermostat on the return pipe set to 70 deg C would do this automatically.

From the suggestions made so far I think an injection Tee will allow me to plumb a pump in parallel with the flow pipe without adding any valves or other impediments to gravity flow, and this is what I'm going to investigate. However I shall experiment first by making up a tee from plastic drinks bottle and pipe, and pumping inky water around, since my gut feeling is that the detailed geometry of the design (see my picture in an earlier post) will be crucial to its performance.

Finally, since I've been rabbiting on for so long I may as well be hanged for a sheep as a lamb, so here is the rationale behind the system.

The original system was heated from the oil-fired boiler only, and the goal of adding the wood burner was to save money and be eco-friendly.

To heat this house through 5 months of winter requires about 3000 litres of oil, which currently costs about £1100 at 35p/litre + VAT. Heating the house with wood requires about 5 tons thereof, and a ton of green (freshly felled) timber which I can log, store and season myself costs about £40. Also we have some trees ourselves which are free, and I have planted over 100 trees so far this year with plans for many more next winter.

As I'm sure you gentlemen (and possibly ladies) know, the heating oil price pretty much tracks the crude oil price and the $/£ exchange rate, reaching over 60p/litre last summer when oil was $150/barrel. In my view it will head that way again sooner rather than later - do your own sums.

The total cost (stove, parts, labour, etc) of installing this setup was about £4750, and I reckon we will save about £750/year at today's prices.

Also there is no denying that a barn full of wood will give me a nice cosy feeling that - regardless of the antics of Bankers, Browns and others - we will at least be warm in winter.

'nuff said!

Firstly the system design. Here is the original schematic diagram which was how I designed it and, in fact, is pretty much how it got built. (Sorry about the size, I'm still using how to learn this forum software, but I think it enlarges if you click on it.)

To recap a little: the heat store is a bog standard 210 litre direct HW cylinder with 2x tappings 180 degrees apart at top and bottom (ie 4 holes in sides and one at top used as a vent here). The flow from (top of cylinder) and return to (bottom) are on one side, and the flow/return to CH system are likewise on the other. All pipework is 28mm.

You'll see from the diagram that there is no direct connection between CH system and stove, but rather that the stove heats the store by gravity convection (over a height of 2 floors), and the the CH system draws hot water from the store when it is available. The actual water and header tank are common, but I'd say it was next to impossible for the CH pump to induce any flow through the stove.

Now for the control system. I designed and built this myself, and I won't bore you with a circuit diagram, but I think a picture of the control panel may help:

Control system

- cbell

- 1

This shows the control panel, and helps to clarify the way the system works ... I hope

The ideas behind this are:

+ Heating should be available on demand at any time, drawing from the heat store if it is hot, and from the oil-fired boiler if it is not.

+ Switchover between heat sources should be automatic, based on the output from a thermostat at the top of the tank. This is set to about 50 deg C, and when this temperature is reached the store is deemed to be "hot".

+ There is also safety circuitry so that when the heat store gets too hot, defined by a 2nd thermostat at its base reaching about 75 deg C, then an override switches on to pump water through the selected CH zone(s) regardless of the state of room stats, timers, etc.

+ The CH system in this house is fully pumped, with 5 zones: 1 being domestic hot water (through a separate indirect cylinder), and the other 4 being various areas of the house. All five zones have separate timer circuits and thermostats controlling their own motorised zone valves.

+ When adding the heat store and wood-burner we added two further motorised valves: one to the oil-fired boiler and one to the heat store. This was to apply positive control over where heat was drawn from, and also to stop heat from the store being pumped through a (cold) boiler, and vice-versa.

I hope you'll all note that there are currently no valves or pumps in the circuit between wood-burner and heat store. Circulation here is purely by gravity convection.

My theory that reverse convection is happening is based on the following evidence:

+ The return pipe from store to stove is significantly hotter than the flow from stove to store. This based both on the evidence of my hand when touching the pipes, and from the dual-channel digital thermometer I have attached to them.

+ If I blaze up the heat store in this state then the return pipe gets even hotter, the flow colder, and before long I get bumping noises from the boilers at the bottom of the stove.

This has only happened twice in 3 months of operation, but on both occasions it was when:

+ The stove had been loaded up in the mid-afternoon, heating the store.

+ At that time of day the CH system is not on, so the store simply heated up.

+ Once it ran out of fuel (after about 2 hours) the fire died right down, and the stove cooled down too.

+ I then refuelled the stove and blazed it up.

Watching the digital thermometer readout (in real-time) I could see the following happening:

(1) Flow temp (from stove to store) rose slightly, starting normal convection, in the range 40 - 50 deg C.

(2) Return temp (from store to stove) then rose sharply to about 70 deg C as - my assumption - hotter water was drawn down from the store.

(3) This effectively stopped and - my assumption again - slightly reversed normal convection flow.

(4) Yet another assumption: this reversal drew hot water from the stove's boilers back up the return pipe, reinforcing the reverse flow. I could see the return temperature rise and the flow fall as this occurred.

(5) Obviously this flow was poor, since it was working against nature, gravity, the thermal gradient in the system (and everything else!) so heat could not escape properly from the stove, at which point water started bumping away as it boiled.

So my original question was "how could I add a pump to the gravity system in order to restore the correct flow direction?". I would want this to be normally off and to switch on in two circumstances:

(1) When the outlet temperature of the stove exceeds about 70 deg C, as experience shows that it is capable when run flat out of raising the water temperature across itself by 30+ deg C under normal gravity flow, causing boiling, therefore increasing the water flow rate would extract heat more quickly and prevent this.

(2) To restore the correct flow direction when the reverse convection I've described above occurs. This would be switched manually, although in fact putting a thermostat on the return pipe set to 70 deg C would do this automatically.

From the suggestions made so far I think an injection Tee will allow me to plumb a pump in parallel with the flow pipe without adding any valves or other impediments to gravity flow, and this is what I'm going to investigate. However I shall experiment first by making up a tee from plastic drinks bottle and pipe, and pumping inky water around, since my gut feeling is that the detailed geometry of the design (see my picture in an earlier post) will be crucial to its performance.

Finally, since I've been rabbiting on for so long I may as well be hanged for a sheep as a lamb, so here is the rationale behind the system.

The original system was heated from the oil-fired boiler only, and the goal of adding the wood burner was to save money and be eco-friendly.

To heat this house through 5 months of winter requires about 3000 litres of oil, which currently costs about £1100 at 35p/litre + VAT. Heating the house with wood requires about 5 tons thereof, and a ton of green (freshly felled) timber which I can log, store and season myself costs about £40. Also we have some trees ourselves which are free, and I have planted over 100 trees so far this year with plans for many more next winter.

As I'm sure you gentlemen (and possibly ladies) know, the heating oil price pretty much tracks the crude oil price and the $/£ exchange rate, reaching over 60p/litre last summer when oil was $150/barrel. In my view it will head that way again sooner rather than later - do your own sums.

The total cost (stove, parts, labour, etc) of installing this setup was about £4750, and I reckon we will save about £750/year at today's prices.

Also there is no denying that a barn full of wood will give me a nice cosy feeling that - regardless of the antics of Bankers, Browns and others - we will at least be warm in winter.

'nuff said!

My theory that reverse convection is happening is based on the following evidence:

+ The return pipe from store to stove is significantly hotter than the flow from stove to store. This based both on the evidence of my hand when touching the pipes, and from the dual-channel digital thermometer I have attached to them.

+ If I blaze up the heat store in this state then the return pipe gets even hotter, the flow colder, and before long I get bumping noises from the boilers at the bottom of the stove.

And I'm saying it cannot happen.

Therefore you are reading it wrong or there's a simple explanation.

Place the thermostats one near the boiler and one near the store, I'm willing to bet the one near the store is hottest.

If, however as you say the flow is going up the return, then the flow is locked, maybe air.

When you first light the stove it stands to reason, that heat transfer to the primary return from the hot store, will make it hotter than the flow, until the flow catches up, it's how the DHW works, cold mains goes in one side and comes out hot.

doitall says

Impasse I'm afraid. It does happen, and short of inviting you round to see for yourself I can't offer any avenue for progress.

I don't want to sound rude, but 30 years experience of Engineering has taught me that when my perception conflicts with the evidence it's usually me who is wrong. As Einstein said when talking about how the universe works, and his puzzlement about it, "God is subtle, but never malicious".

I agree that I could be reading it wrong, but I don't think so. The evidence of the nerve endings in my fingers when touching the pipes is confirmed by the readings from the thermometer. So both carbon-based and silicon-based measurement methods seem to agree with one another.

There is, of course, an explanation - but whether it is simple or not I can't say.

Let us assume for a moment that I am not deluded, and that it does happen - the question is either "how do I prevent it" or, if I can't prevent it, "how do I restore normal circulation".

And I'm saying it cannot happen.

Impasse I'm afraid. It does happen, and short of inviting you round to see for yourself I can't offer any avenue for progress.

I don't want to sound rude, but 30 years experience of Engineering has taught me that when my perception conflicts with the evidence it's usually me who is wrong. As Einstein said when talking about how the universe works, and his puzzlement about it, "God is subtle, but never malicious".

Therefore you are reading it wrong or there's a simple explanation.

I agree that I could be reading it wrong, but I don't think so. The evidence of the nerve endings in my fingers when touching the pipes is confirmed by the readings from the thermometer. So both carbon-based and silicon-based measurement methods seem to agree with one another.

There is, of course, an explanation - but whether it is simple or not I can't say.

Let us assume for a moment that I am not deluded, and that it does happen - the question is either "how do I prevent it" or, if I can't prevent it, "how do I restore normal circulation".

My pump with swept tees would do that!

You could monitor the temperature of each pipe, ideally about half way up, and then trigger a 555 timer to run the pump for about 15 seconds to correct the direction of flow!

I dont think your diagram is likely to be what you have fitted. Surely the water in the rads, oil boiler and wood stove is not all the same is it?

Tony

You could monitor the temperature of each pipe, ideally about half way up, and then trigger a 555 timer to run the pump for about 15 seconds to correct the direction of flow!

I dont think your diagram is likely to be what you have fitted. Surely the water in the rads, oil boiler and wood stove is not all the same is it?

Tony

I don't mind you being rude or sounding rude for that matter, 20 years on various forums you get used to it.

Back to the problem, over 50 years as an engineer, I'm telling you it cannot happen under normal conditions.

To get reverse circulation the flow has to be locked or there's a driving force on the flow, which is stopping circulation.

The problem, points to a fault in the appliance, store, or pipework.

To get around the problem without solving it, and inverted loop/bye pass in the return with a pump, as per one of the earlier drawings.

What is the make model of the store, and what was the reason for no expansion pipe on the primary flow.

What part of Devon are you.

Back to the problem, over 50 years as an engineer, I'm telling you it cannot happen under normal conditions.

To get reverse circulation the flow has to be locked or there's a driving force on the flow, which is stopping circulation.

The problem, points to a fault in the appliance, store, or pipework.

To get around the problem without solving it, and inverted loop/bye pass in the return with a pump, as per one of the earlier drawings.

What is the make model of the store, and what was the reason for no expansion pipe on the primary flow.

What part of Devon are you.

I can envisage a situation where the reverse direction flow could start.

This can be particulary the case if the pipework has not been done by a professional who is experienced with the best way to get a gravity system to work.

The "head" on a gravity system at the "start" will be hardly more than a few millemeters and the direction it starts in can be easily disturbed.

I would take the stove return down to floor level, or below, but I expect it only goes down as far as the return!

Tony

This can be particulary the case if the pipework has not been done by a professional who is experienced with the best way to get a gravity system to work.

The "head" on a gravity system at the "start" will be hardly more than a few millemeters and the direction it starts in can be easily disturbed.

I would take the stove return down to floor level, or below, but I expect it only goes down as far as the return!

Tony

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 4

- Views

- 6K

- Replies

- 44

- Views

- 7K

- Replies

- 5

- Views

- 2K

- Replies

- 60

- Views

- 7K