Last December we fitted a fully boilered wood-burner to our central heating system. It's a really simple setup:

- Wood-burner heats store (210 litre direct copper cylinder) in roof by gravity convection.

- Thermostat on heat store says "I'm hot" when it reaches about 55 deg C.

- When the (fully pumped) CH system wants heat it opens the zone valve to the heat store if this is hot, and draws water from there; otherwise it opens the valve to the boiler, fires this up, and takes it from there.

It works very well except from one unexpected problem:

If the heat store is quite hot (say 70+ deg C), and there is no demand on it, and the wood-burner dies right down so that its boiler temperature is less than that of the heat store, then convection stops. So far, so good.

However if you load up the wood-burner so that convection starts again it can draw down water from the heat store that is actually hotter than that in the boiler, resulting in the flow direction reversing. Once this happens it seems to be impossible to stop until the wood-burner has gone out and the temperature of the pipework on both flow and return has reverted to ambient.

I think I've diagnosed the problem correctly since I have a dual channel digital thermometer connected to flow and return, and can measure their temperatures accurately. This, combined with the bumping noises as the boiling water can't escape from the wood-burner, makes me pretty confident that this is what is going on.

This has only happened twice and I can manage the problem by not letting the fire die right back, or by drawing some heat from the store (so that the temperature at its base drops) before refuelling a luke-warm stove. However I'd like to prevent this happening, and the only solution I can think of is to add a pump to the gravity circulation circuit between wood-burner and heat store which could be switched on manually to restore the "correct" flow direction.

However this is a bit of contradiction in terms: gravity circuits are - by definition - not pumped, and I'd like to preserve the gravity circulation aspect of the system for safety's sake in the event of a power or pump failure. So, finally, here is the question:

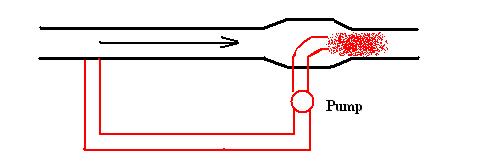

Is there an accepted way of fitting a part-time pump to a gravity system? I can imagine two solutions: one being a pump with a low resistance to flow simply plumbed in series, the other being to insert a section with a low resistance non-return valve, and run the pump in parallel with this.

All ideas welcome!

- Wood-burner heats store (210 litre direct copper cylinder) in roof by gravity convection.

- Thermostat on heat store says "I'm hot" when it reaches about 55 deg C.

- When the (fully pumped) CH system wants heat it opens the zone valve to the heat store if this is hot, and draws water from there; otherwise it opens the valve to the boiler, fires this up, and takes it from there.

It works very well except from one unexpected problem:

If the heat store is quite hot (say 70+ deg C), and there is no demand on it, and the wood-burner dies right down so that its boiler temperature is less than that of the heat store, then convection stops. So far, so good.

However if you load up the wood-burner so that convection starts again it can draw down water from the heat store that is actually hotter than that in the boiler, resulting in the flow direction reversing. Once this happens it seems to be impossible to stop until the wood-burner has gone out and the temperature of the pipework on both flow and return has reverted to ambient.

I think I've diagnosed the problem correctly since I have a dual channel digital thermometer connected to flow and return, and can measure their temperatures accurately. This, combined with the bumping noises as the boiling water can't escape from the wood-burner, makes me pretty confident that this is what is going on.

This has only happened twice and I can manage the problem by not letting the fire die right back, or by drawing some heat from the store (so that the temperature at its base drops) before refuelling a luke-warm stove. However I'd like to prevent this happening, and the only solution I can think of is to add a pump to the gravity circulation circuit between wood-burner and heat store which could be switched on manually to restore the "correct" flow direction.

However this is a bit of contradiction in terms: gravity circuits are - by definition - not pumped, and I'd like to preserve the gravity circulation aspect of the system for safety's sake in the event of a power or pump failure. So, finally, here is the question:

Is there an accepted way of fitting a part-time pump to a gravity system? I can imagine two solutions: one being a pump with a low resistance to flow simply plumbed in series, the other being to insert a section with a low resistance non-return valve, and run the pump in parallel with this.

All ideas welcome!