If the welder will run from a B32 MCB then it will also run from a C16 MCB as the magnet part of the trips will trip at the same current.

However the 13A fuse will take a fair in rush

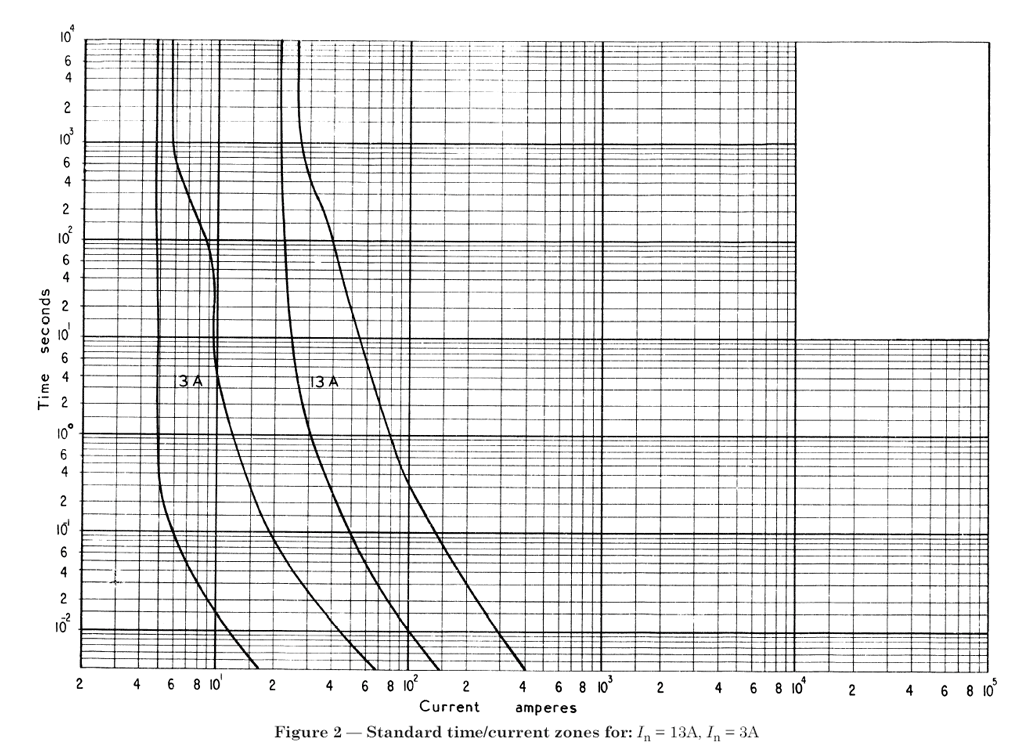

looking at these curves the 160A required to trip a B32 or C16 MCB can be handled for around 0.06 seconds with a 13A fuse so there is no guarantee that a C16 will hold.

With the moving core type of welding machine turning to low setting before turning on does help.

Most people want to move the welder and to need a dedicated supply really limits the use one can put the welder to. Most of the welders I have used designed to be portable use a switch mode system and are refereed to as inverters rather than transformers. These have a build in soft start and can run with a 13A fuse far longer than the old transformer type.

But standard with a welder is 25 volt plus 1 volt per 25A so at 250A the running volts will be approx 35 volt at 250A = 8.75kW at 230v this is around 38A which is well over double what a 16A MCB can provide. And that's also true for an inverter which is greater than whole supply to garage.

I have seen this before where welders have come with completely the wrong size plug. I would guess the plug has been fitted by the importer?

You do need to read the plate of course but I would suspect you will need a 32A outlet not 16A.

Not used a plasma cutter but have used Air Arc and that really does load up the units in the past I have needed to run welders in tandem to get the current required which would melt 35mm cables had to be at least 50mm better at 70mm. These are real beasts and we always used motor driven because of the power required.

A 13A supply max around 105A output

A 16A supply max around 125A output

A 30A supply max around 210A output

A 32A supply max around 220A output

And this is not allowing for in-rush or losses so seems you have been sold a pup! Sorry but better you know now before you spend out more.

my question is can i wire in a designated 16A socket from my workshop RCD board and how????

my question is can i wire in a designated 16A socket from my workshop RCD board and how????