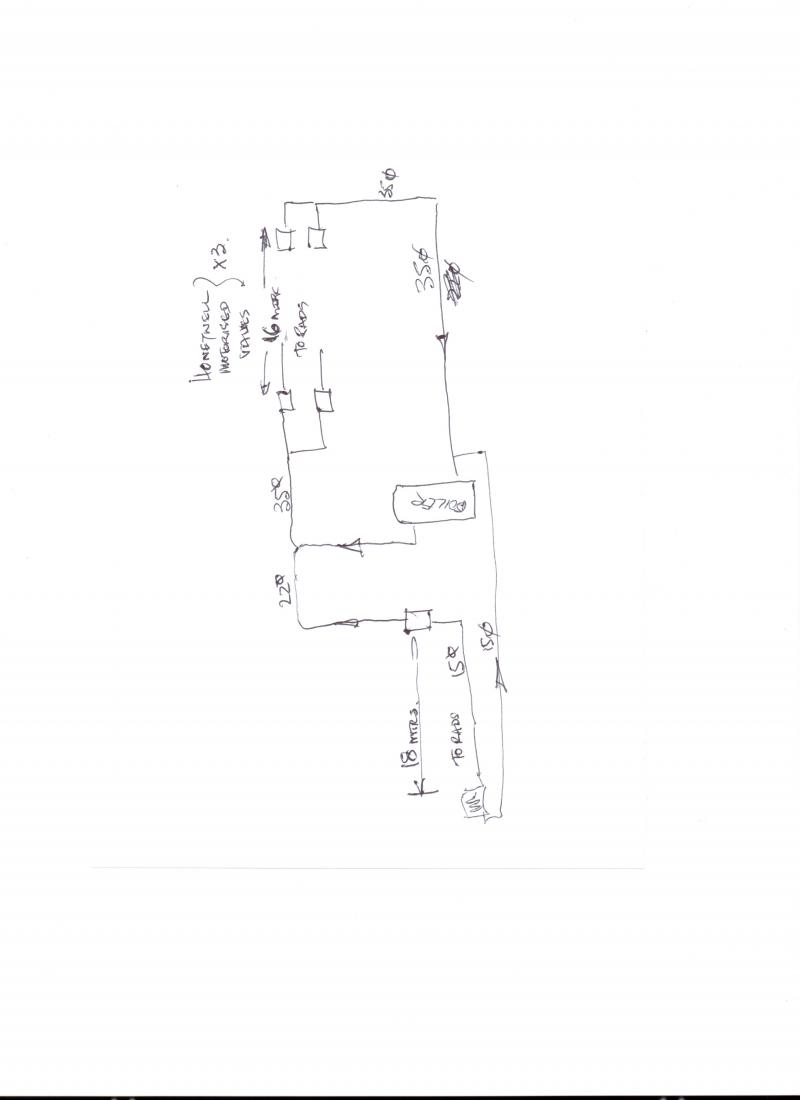

I have done the 'whole house calcs, and at first run it comes to 32kW -I assume we need some safety factor, and felt that the modulation would reduce the 40kW acceptably.

The 32kW already includes a safety factor. The only advantage of having a 40kW boiler would be that it can provide more heat when it is very very cold. e.g -6C.

Yes the pump sizing may be in error, and would think one larger pump may well be a better route.

Thinking about it further, I doubt if installing a larger pump will solve your problem; it may make it worse.

The most you should send along a 15mm pipe is 7kw, which means an average of 1kW per rad. If you have more than this, the water speed will be too high, meaning more friction and a greater pressure loss in that section.

I know you think balancing may not solve the problem, but its worth giving it a go. Here's a quick method:

Remove all TRV heads and set any wheel-head valves to fully open

Close all lock-shield valves then open them half a turn.

Check the return pipes of each rad, by feel. If any are too hot, close the LS valve an eighth of a turn; vice versa if too cold

The idea is to have the return pipe (cooler one) of each rad at approximately the same temperature.

Adjust one rad at a time and wait 10 minutes before checking.

Adjusting one rad may affect others.