Hi all,

I've reposted this to the 'Building' forum as it wasn't get much of a response in the 'Your Projects' forum...

I'm DIYing a conversion of a single block work shed in our garden to make a home office. We've had some roof leaks from the one verge due to poor mortar bedding which has saturated one of the walls but this has now been fixed. Now it's dried out I'm looking to insulate, stud and dry-line it but have been going round in circles with regards to the floor/wall detail, especially with regards to where to fix the soleplate for the studwork, and how to ensure we don't affect the integrity of the DPM.

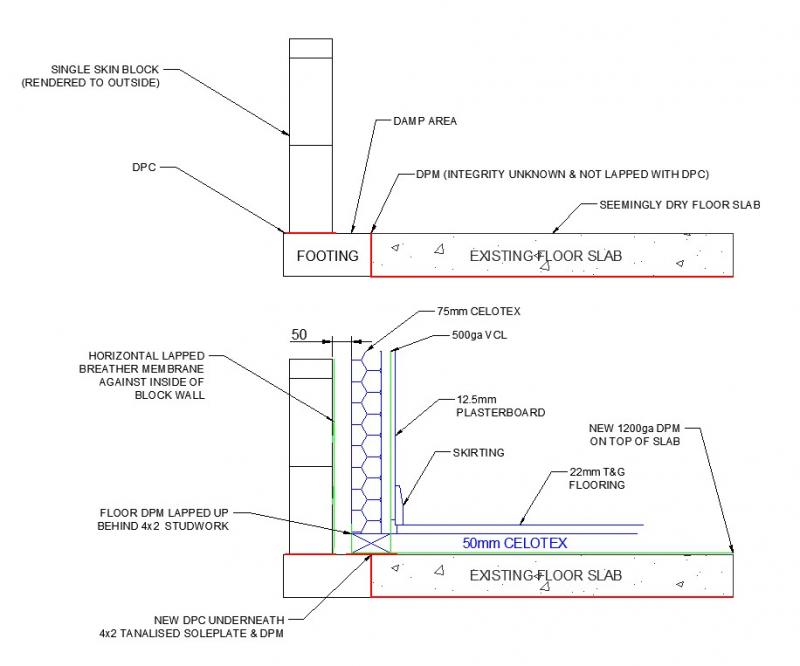

I've attached a drawing showing the existing situation and one option I'm considering.

There's one slight anomaly/issue - when it was built the builder didn't lap the DPM below the floor slab with the wall DPC, but instead cut it off at floor level leaving a 4" strip of footing between the floor slab and wall which is damp to the touch. This moisture may have been a result of the leaky roof but it may also be due to ground moisture.

What I was thinking of doing is as follows:

1. Applying liquid damp proofing over the 4" gap to seal it.

2. Lining the outer walls with horizontally lapped breather membrane

3. Laying a DPM over the floor slab (not sure on the integrity of the one below the slab so just in case...)

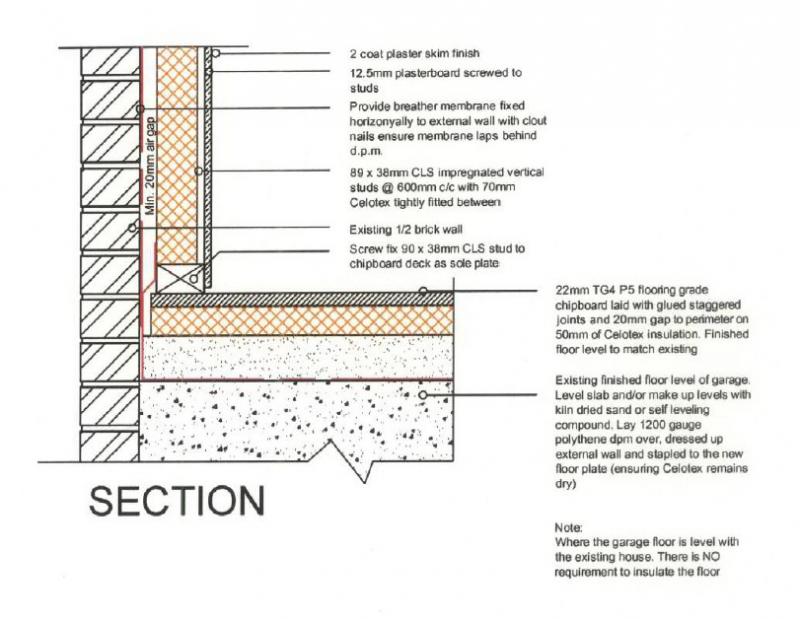

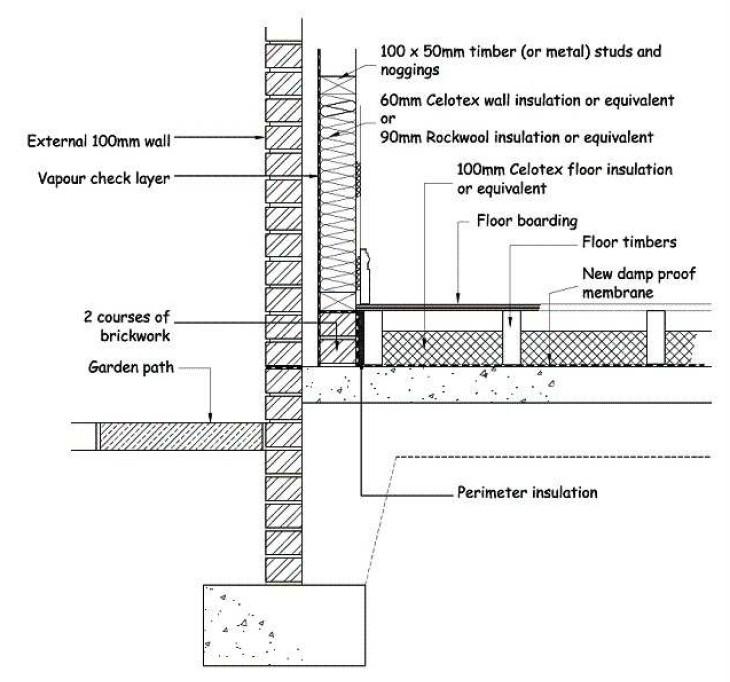

4. Installing tanalised 4x2 soleplate 2" from the wall over the DPM but with a DPC below, screwing down through both into the concrete, then bringing the DPM up the back of the soleplate for a nominal distance

5. Firing studs up from the soleplate to a top plate in the roof trusses, insulate between, VCL and 12.5mm plasterboard

6. Laying 50mm Celotex up to the inner edges of the soleplate with 22mm T&G chipboard over, allowing a gap for the T&G expansion

However, there also seem to be the following options:

1. To take the DPM and flooring out further and fix the soleplate to the chipboard floor - seems like an easier option but possible concerns over floor movement resulting in the stud moving/plaster cracking

2. To build a single course inner brick wall on the slab with DPC below, run the DPM over it and screw the soleplate to the brick through the DPM - seems like a bit more work.

There's no low level vents in the outer block wall, just the soffit ventilation at the top of the wall.

I'd appreciate all/any comments you have relating to the above/attached drawing.

Thanks

Ross

I've reposted this to the 'Building' forum as it wasn't get much of a response in the 'Your Projects' forum...

I'm DIYing a conversion of a single block work shed in our garden to make a home office. We've had some roof leaks from the one verge due to poor mortar bedding which has saturated one of the walls but this has now been fixed. Now it's dried out I'm looking to insulate, stud and dry-line it but have been going round in circles with regards to the floor/wall detail, especially with regards to where to fix the soleplate for the studwork, and how to ensure we don't affect the integrity of the DPM.

I've attached a drawing showing the existing situation and one option I'm considering.

There's one slight anomaly/issue - when it was built the builder didn't lap the DPM below the floor slab with the wall DPC, but instead cut it off at floor level leaving a 4" strip of footing between the floor slab and wall which is damp to the touch. This moisture may have been a result of the leaky roof but it may also be due to ground moisture.

What I was thinking of doing is as follows:

1. Applying liquid damp proofing over the 4" gap to seal it.

2. Lining the outer walls with horizontally lapped breather membrane

3. Laying a DPM over the floor slab (not sure on the integrity of the one below the slab so just in case...)

4. Installing tanalised 4x2 soleplate 2" from the wall over the DPM but with a DPC below, screwing down through both into the concrete, then bringing the DPM up the back of the soleplate for a nominal distance

5. Firing studs up from the soleplate to a top plate in the roof trusses, insulate between, VCL and 12.5mm plasterboard

6. Laying 50mm Celotex up to the inner edges of the soleplate with 22mm T&G chipboard over, allowing a gap for the T&G expansion

However, there also seem to be the following options:

1. To take the DPM and flooring out further and fix the soleplate to the chipboard floor - seems like an easier option but possible concerns over floor movement resulting in the stud moving/plaster cracking

2. To build a single course inner brick wall on the slab with DPC below, run the DPM over it and screw the soleplate to the brick through the DPM - seems like a bit more work.

There's no low level vents in the outer block wall, just the soffit ventilation at the top of the wall.

I'd appreciate all/any comments you have relating to the above/attached drawing.

Thanks

Ross