If memory serves me right I recall from decades ago fuse boxes had to be made out of non conductive material ( mostly wood ) to prevent people getting shocks from them in the event of insulation failure.

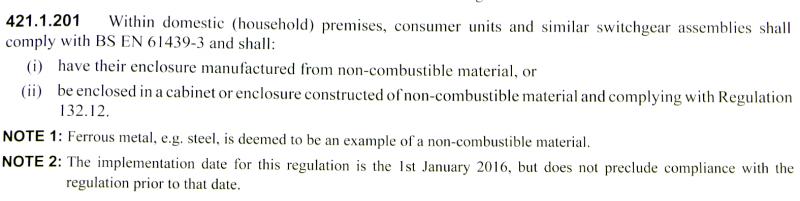

There are fires started by a CU bursting into flames so they should be made from non combustible material but to make them conductive is in my opinion a back ward step.

If there is a problem with the electrics the first place a person will go to is the consumer unit. If the earth connection to the case of the consumer unit has failed as well as the other fault the case of the consumer unit could be lethal to the touch if the person has a good second point of contact to ground.

There are fires started by a CU bursting into flames so they should be made from non combustible material but to make them conductive is in my opinion a back ward step.

If there is a problem with the electrics the first place a person will go to is the consumer unit. If the earth connection to the case of the consumer unit has failed as well as the other fault the case of the consumer unit could be lethal to the touch if the person has a good second point of contact to ground.