Has anyone ever worked out the carbon footprint for producing a wind turbine?

Not just the different energies used in the manufacturing of one, which should include the energy used to power the factories as well as the machinery but also the original sourcing of the materials, steel, aluminium, copper etc. Once the various parts are made and partly assembled they then have to transport them to the site where more energy is used in the final assembly. But it doesn't end there. You have to use energy to route where the power cables for the collected energy go to, factor in the power used towards maintenance etc.

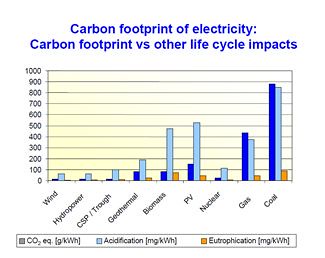

I know someone is going to come up with the argument that all other forms need to have these calculations thrown in as well, and I agree, however to get a TRUE cost of which is the most efficient way of obtaining energy you have to do what is called a Value Stream Map. This is where a Lean Practitioner comes into the equation. They have the knowledge of how to calculate all the data required and produce a true picture. Problem is governments don't really like them because they can often prove official statistics are incorrect.