- Joined

- 27 Nov 2019

- Messages

- 27

- Reaction score

- 0

- Country

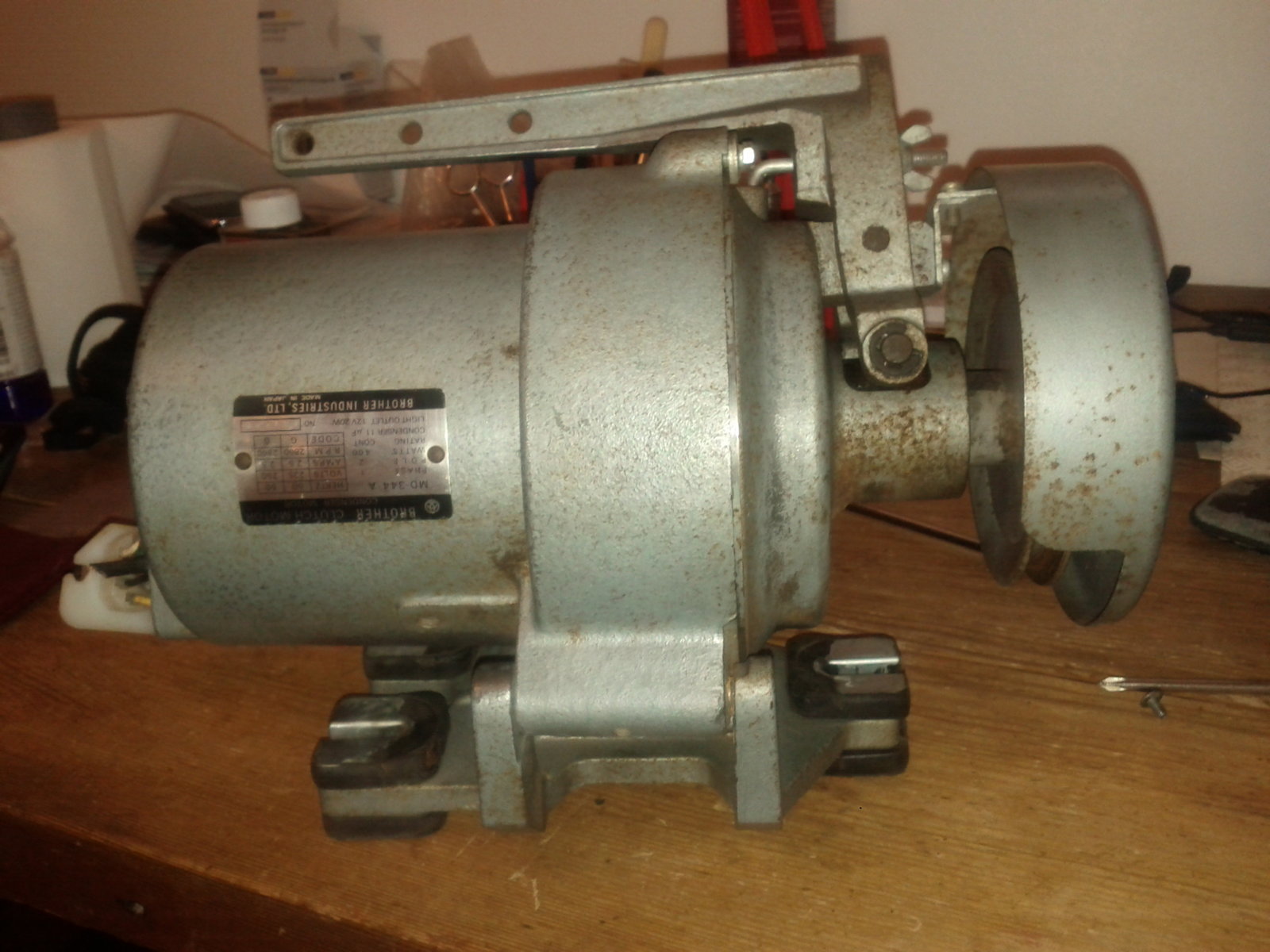

I have a Brother single phase clutch motor with a multi pin connector block on the back.

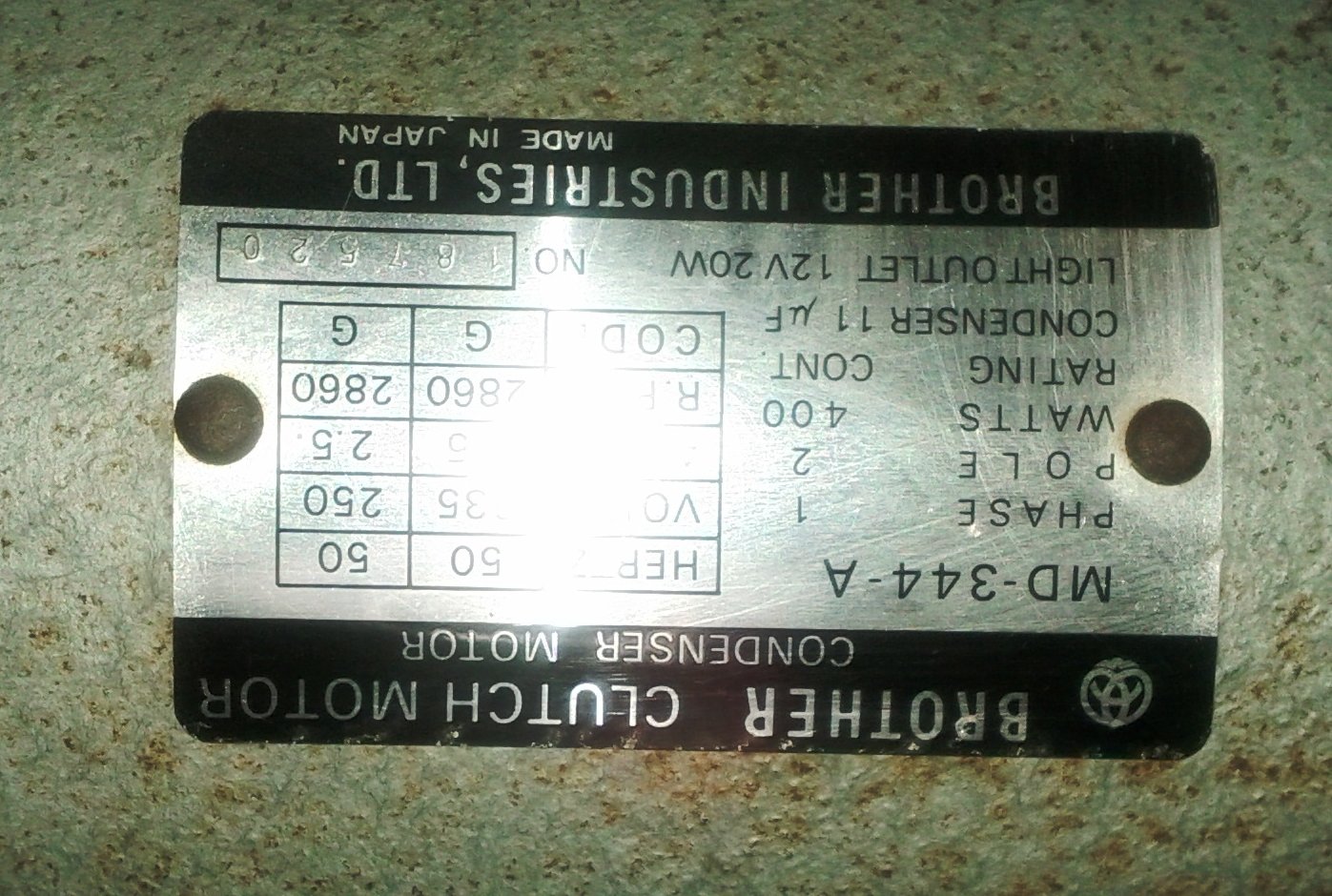

Here is the data plate...

Sorry, I don't know why it's upside down - it's the right way up on my lap top. This is the connector block..

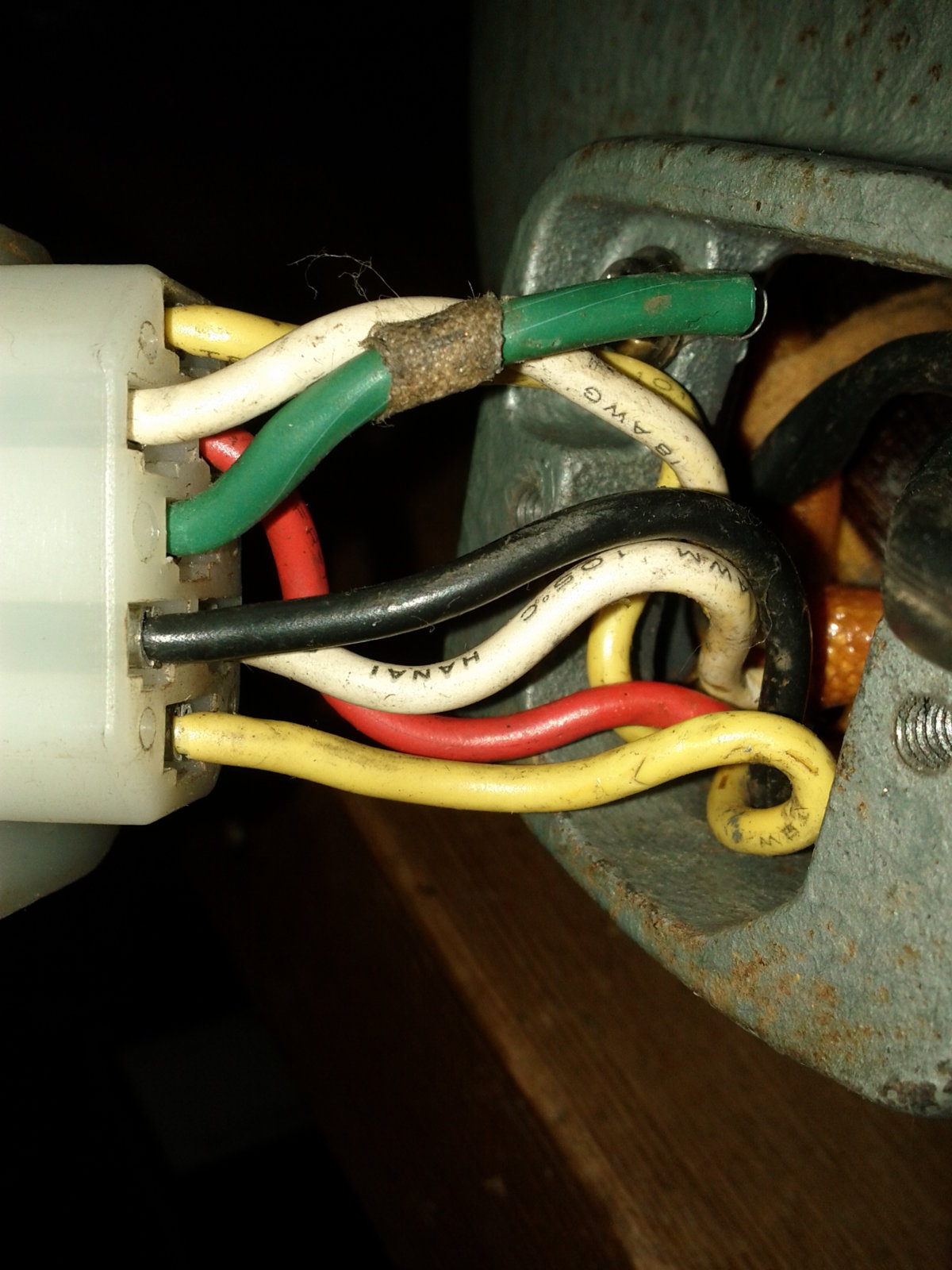

I don't have the female plug so I'm not sure how to connect the motor to the mains. Here is a picture of the wires coming out if the motor to the male connector (you can ignore the black twin core, that's for the work light)...

The red, black & green are, I assume, live, neutral and earth respectively. But what are the yellow and white pairs for? I know some sewing machines were fitted with reversing switches; could that be it? In any event, how I can connect this motor to my domestic supply using a standard 3-pin plug? Can I ignore the yellow and white wires and connect live to live and neutral to neutral?

Thank you in advance - Joe

Here is the data plate...

Sorry, I don't know why it's upside down - it's the right way up on my lap top. This is the connector block..

I don't have the female plug so I'm not sure how to connect the motor to the mains. Here is a picture of the wires coming out if the motor to the male connector (you can ignore the black twin core, that's for the work light)...

The red, black & green are, I assume, live, neutral and earth respectively. But what are the yellow and white pairs for? I know some sewing machines were fitted with reversing switches; could that be it? In any event, how I can connect this motor to my domestic supply using a standard 3-pin plug? Can I ignore the yellow and white wires and connect live to live and neutral to neutral?

Thank you in advance - Joe

Last edited: