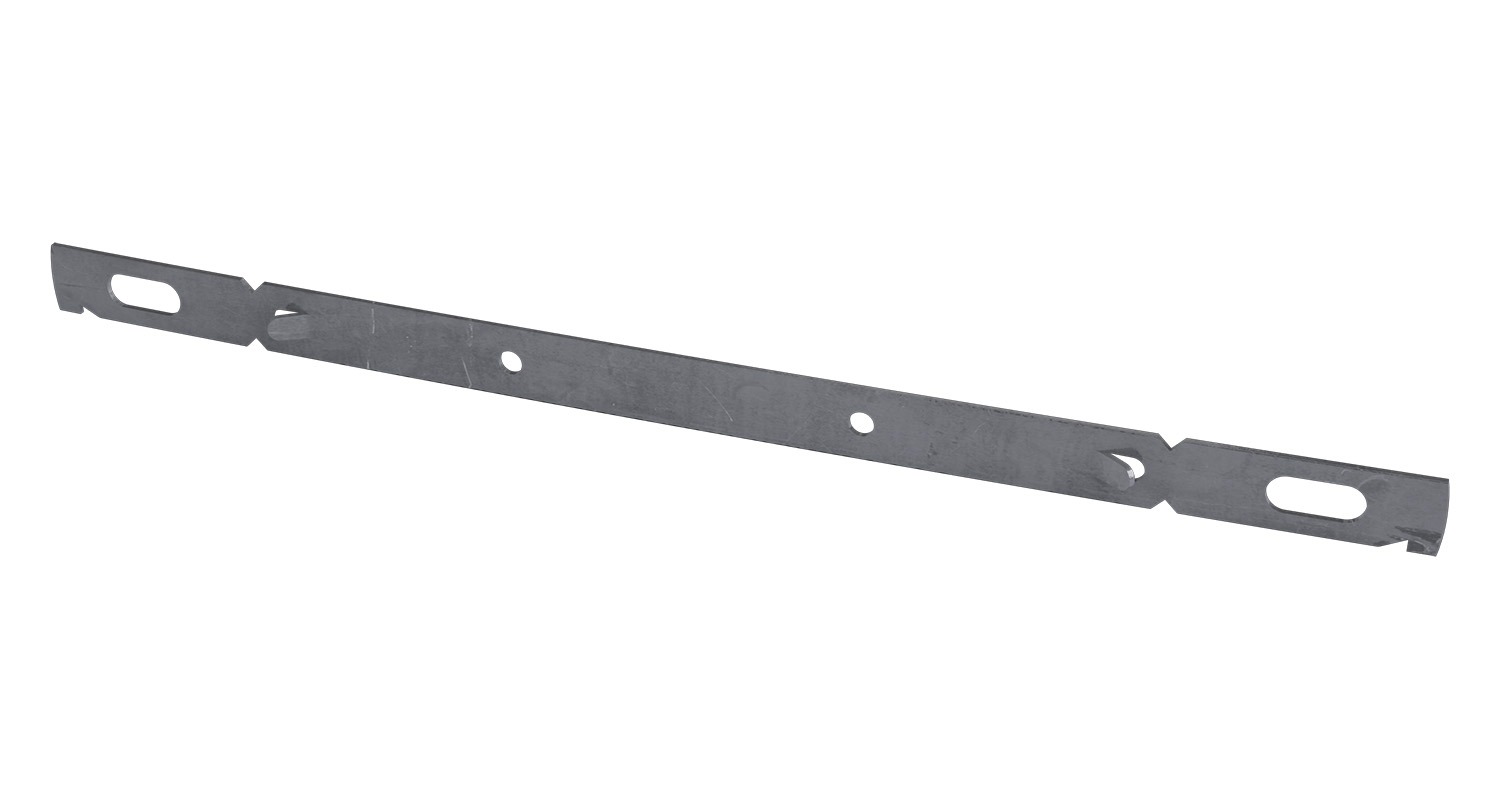

New to the UK, and I am pouring a grade beam for a workshop that I am building. In Canada (the land of basements), concrete forms are made of 3/4 plywood held together with snap ties, that have slots in them that you slide flat metal bars (waler bars) that hold the forms at a fixed distance. After the concrete sets, you slide the bars out and snap off the ends of the ties.

What do they use in the UK for this purpose?

What do they use in the UK for this purpose?