- Joined

- 9 Jun 2021

- Messages

- 14

- Reaction score

- 0

- Country

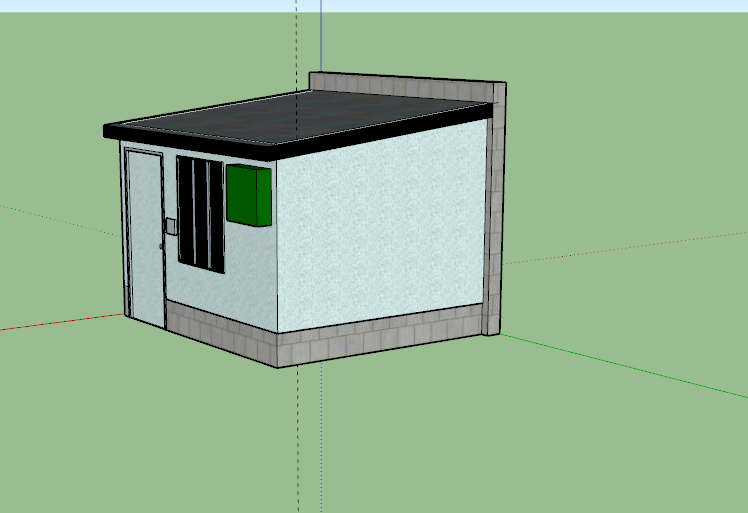

Hi I am needing to build an 8ft high concrete block wall where a pent shed will be built from using a wooden frame and foam panels for light weight while the concrete wall is to stop damages encase of accidents while the light weight section will give. I am wanting to use standard concrete blocks. My footings are 1m deep as its clay soil to pure clay then hardened clay by 450mm wide with 12" concrete footing. The wall needs to go around 8ft tall but I know that will not work with a single skin. So I am wondering is it best to place the concrete blocks on their side so they are lay flat and will this stand fine at a single skin to 8ft tall? Or would it be best to do two skins side by side with block, no cavity, and tie these in periodically with wall ties or another idea is to do to blocks standard way up so 200mm thick then lay one flat on top then another flat then two standard until up to 8ft tall and would this hold fine? or would simply doing columns at either end on one side of the wall with the rest single skin hold fine? Building is 10x8.5ft in size. The interior will have a small wall coming away from the end to around 3 foot in and walled off again to the sides to create two small rooms which will store compressed gas and again will be a single skin wall with wood frame and plastered then tiled with an open roof to the wooden roof section.

The shed will connect by the wooden frame to this and the bottom will have 3 coarse of block , before the wood starts, to lift it away from the ground with these tying into the shielding wall at the rear. The roof will slope away from the rear wall down to the front.

The shed will connect by the wooden frame to this and the bottom will have 3 coarse of block , before the wood starts, to lift it away from the ground with these tying into the shielding wall at the rear. The roof will slope away from the rear wall down to the front.