Hi there, I am a little clueless about something and came to you because no existing page seemed to be of any help, and the search for "DIY forums" had you as first result.

For a school project, I am going to be using LEDs, and the tech department seem unable to help.

I would want my device to plug into the mains, and have around 514 bright LEDs.

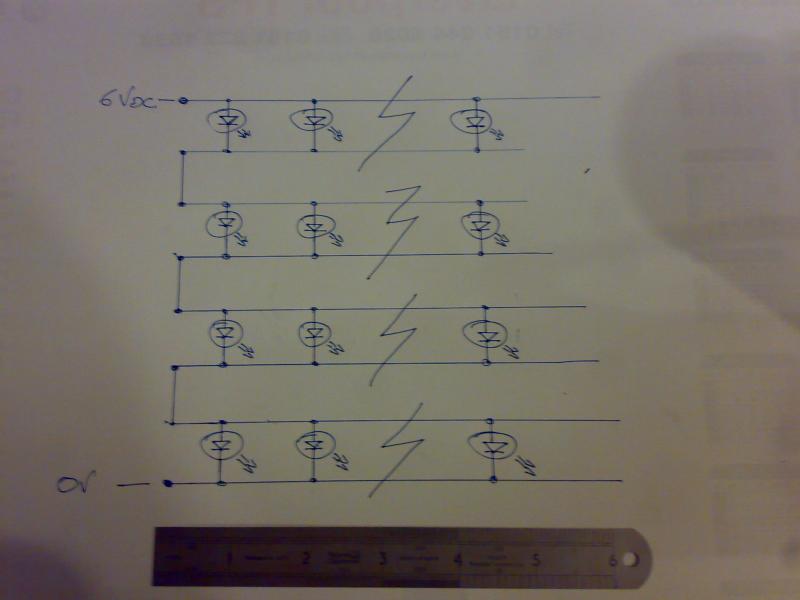

The configuration could be any of the following:

- 514 LEDs in serial

- A set of 257 serially connected LEDs, connected in parallel to another set of 257 serially connected LEDs.

- Sets of serially connected LEDs in these lengths: 5, 12, 30, 39, 34, 34, 34, 6, 6, 5, 5, 21, 18, 8, 5, 12, 30, 39, 34, 34, 34, 6, 6, 5, 5, 21, 18, 8, with each set connected in parallel with the next

It doesn't matter what LEDs I use, as long as they are very bright. To give context, they are about 5mm behind a layer of very thin acrylic, and they are to make it have a sort of glow.

So my question is, firstly, will normal mains power be able to support such a task, or willI have to cut back?

If I do have to cut back, what is the maximum number I can use?

Will mains power be too much? will I have to use a transformer or resistor? can you give me info on what step/how many ohms?

What configuration of serial/parallel should I use?

please give as much detail as possible, and preferably the reasoning so I can learn from this.

Thanks in advance,

Perro

For a school project, I am going to be using LEDs, and the tech department seem unable to help.

I would want my device to plug into the mains, and have around 514 bright LEDs.

The configuration could be any of the following:

- 514 LEDs in serial

- A set of 257 serially connected LEDs, connected in parallel to another set of 257 serially connected LEDs.

- Sets of serially connected LEDs in these lengths: 5, 12, 30, 39, 34, 34, 34, 6, 6, 5, 5, 21, 18, 8, 5, 12, 30, 39, 34, 34, 34, 6, 6, 5, 5, 21, 18, 8, with each set connected in parallel with the next

It doesn't matter what LEDs I use, as long as they are very bright. To give context, they are about 5mm behind a layer of very thin acrylic, and they are to make it have a sort of glow.

So my question is, firstly, will normal mains power be able to support such a task, or willI have to cut back?

If I do have to cut back, what is the maximum number I can use?

Will mains power be too much? will I have to use a transformer or resistor? can you give me info on what step/how many ohms?

What configuration of serial/parallel should I use?

please give as much detail as possible, and preferably the reasoning so I can learn from this.

Thanks in advance,

Perro