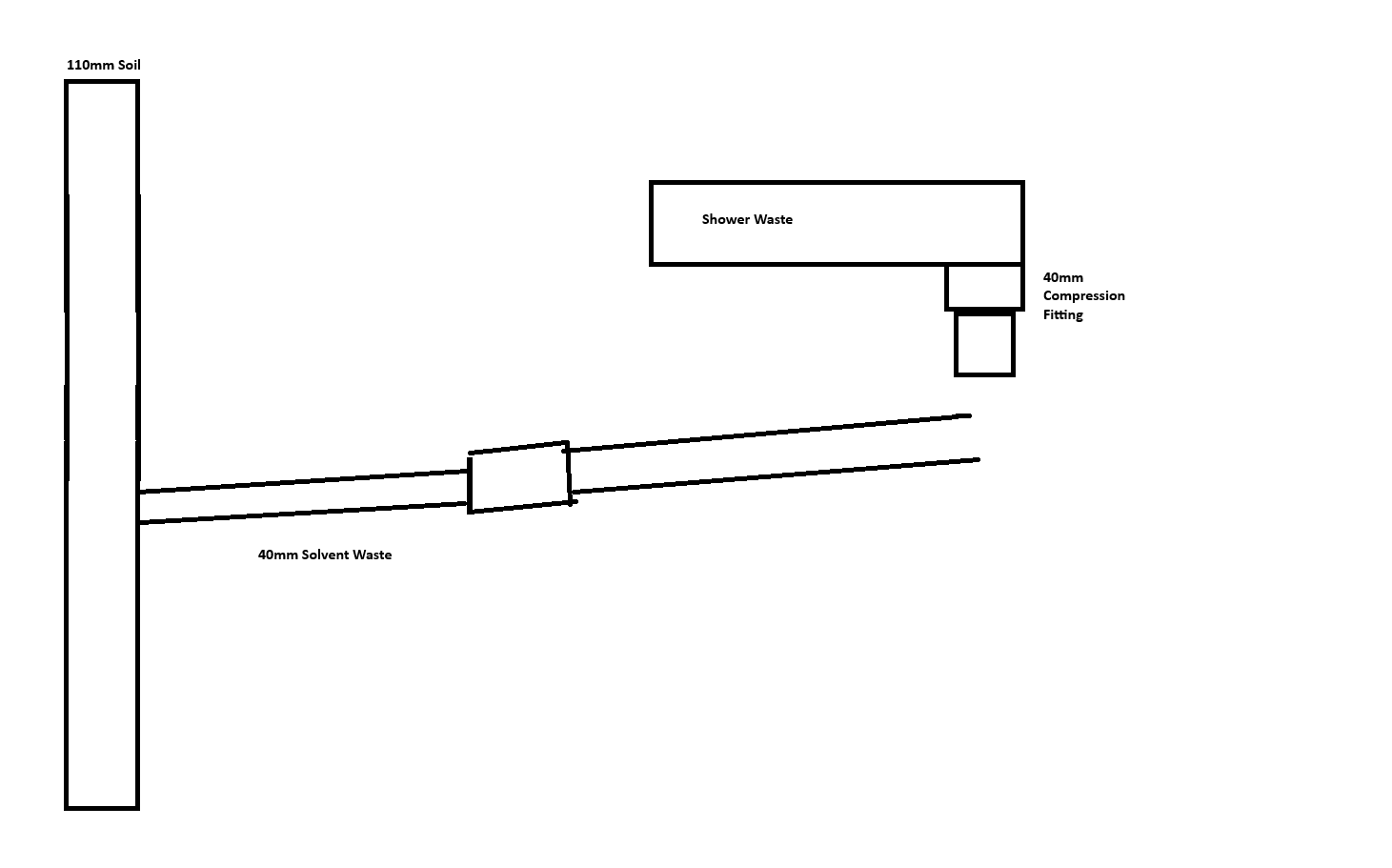

I’ve installed my shower tray and run a 40mm waste pipe from the soil pipe, as shown in my drawing attached below. At the moment, the 40mm pipe is only run up to the point where I plan to add a coupler — it’s currently cut and capped just to stop smells.

I’ve made an access hatch from below so I can fit the shower waste trap. The trap is a rectangular type with a 40mm outlet. The vertical drop from the shower drain to the horizontal 40mm pipe will be about 40cm.

The horizontal pipe from the soil pipe already has a slight fall, so I’m trying to figure out the best way to connect everything without it turning into a fight. Ideally, I’d like to use a solvent-weld coupler to join the final section to the existing 40mm pipe, but I’m worried I won’t have enough play to manoeuvre it into place.

I’ve seen people use some sort of slip compression connectors, but since it’s a shower waste I’d rather avoid compression fittings if possible.

One idea is to allow a bit of movement in the horizontal pipe so it can drop slightly, making it easier to slide the trap and pipe together — but I’m not sure there’s enough flexibility to do that. I’ll test-fit it first, although dry fitting can be tricky because solvent-weld fittings don’t always push fully home until the glue is applied.

If anyone has tips or advice on the best way to approach this, I’d really appreciate it.

Thanks in advance.

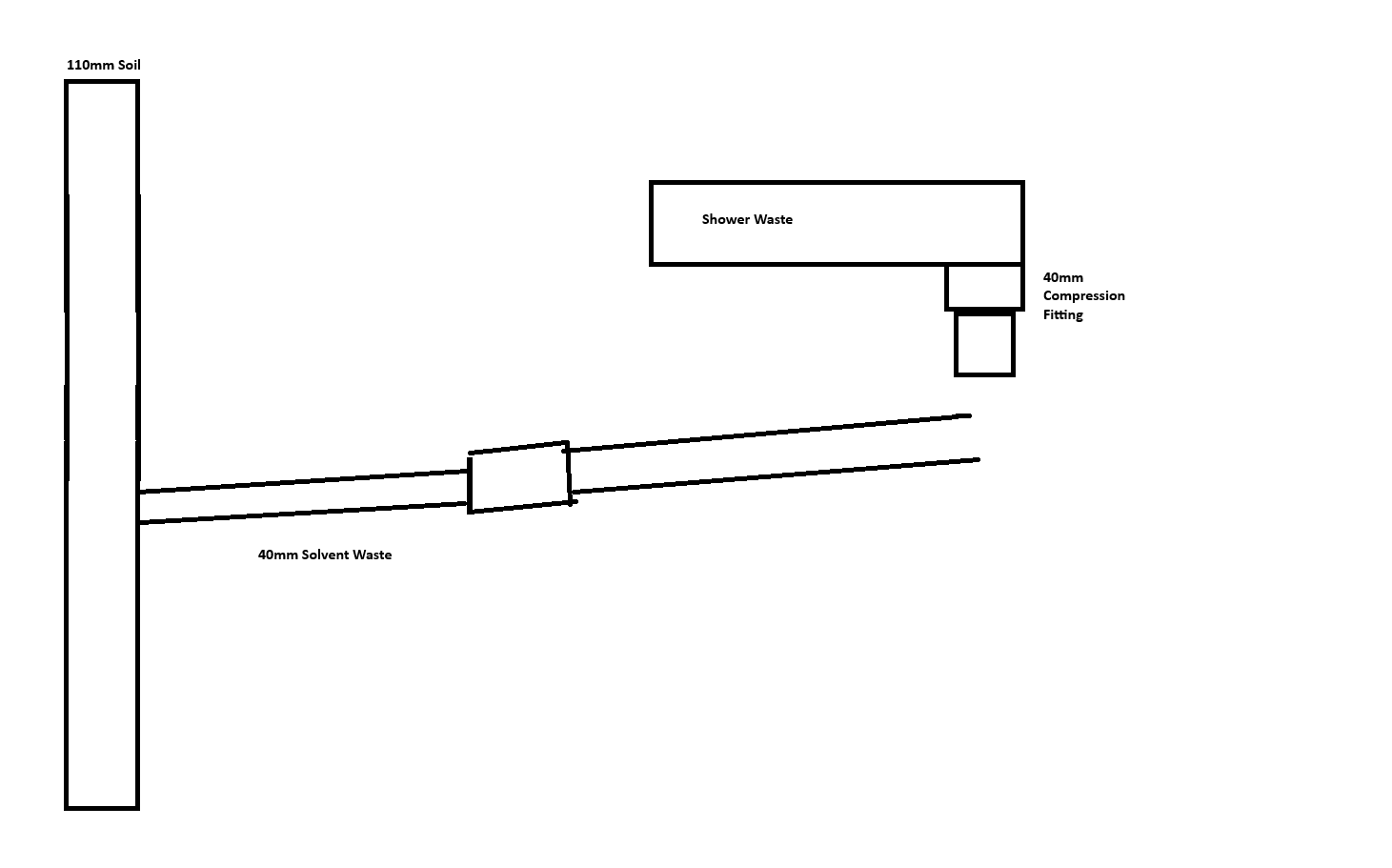

I’ve made an access hatch from below so I can fit the shower waste trap. The trap is a rectangular type with a 40mm outlet. The vertical drop from the shower drain to the horizontal 40mm pipe will be about 40cm.

The horizontal pipe from the soil pipe already has a slight fall, so I’m trying to figure out the best way to connect everything without it turning into a fight. Ideally, I’d like to use a solvent-weld coupler to join the final section to the existing 40mm pipe, but I’m worried I won’t have enough play to manoeuvre it into place.

I’ve seen people use some sort of slip compression connectors, but since it’s a shower waste I’d rather avoid compression fittings if possible.

One idea is to allow a bit of movement in the horizontal pipe so it can drop slightly, making it easier to slide the trap and pipe together — but I’m not sure there’s enough flexibility to do that. I’ll test-fit it first, although dry fitting can be tricky because solvent-weld fittings don’t always push fully home until the glue is applied.

If anyone has tips or advice on the best way to approach this, I’d really appreciate it.

Thanks in advance.