I am not sure what we are discussing. You have just worked out the absolute minimum diameter for four 2.5mm² conductors. The fact that it is possible to insert two 2.5mm² with folded ends, albeit pinched tightly, or three 4mm² conductors into the terminal easily without force means that the terminals are larger than this.

Some are square.

Well, primarily I was trying to illustrate the flaw in your assertion (complete with dictionary definitions

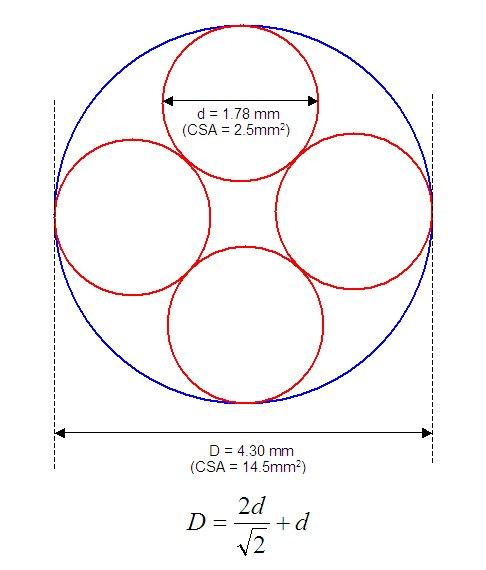

) that if a terminal has the capacity to take 3x4mm² conductors or 2x6mm² conductors then it necessarily must have the capacity to accommodate four (or maybe even five) 2.5mm² conductors. As I hope I've illustrated, if the terminal hole is circular, and if the (stranded) 3x4mm² conductors or 2x6mm² conductors can be made to 'just fit', the four 2.5mm² ones almost certainly would

not fit. As I said, the crucial difference is that the 2.5mm² conductor is solid, whereas the others are stranded (hence their 'shape' can be changed).

However, as a secondary motive, I was also trying to see if I could find a way in which the MK MIs made sense, in saying that the maximum capacity was only 3x2.5mm², whereas it had the capacity for 3x4mm² conductors or 2x6mm² conductors. Qualitatively, I've certainly found a possible type of explanation. As below, maybe they feel that, because they are solid, four 2.5mm² conductors would be 'too tight' in their terminal.

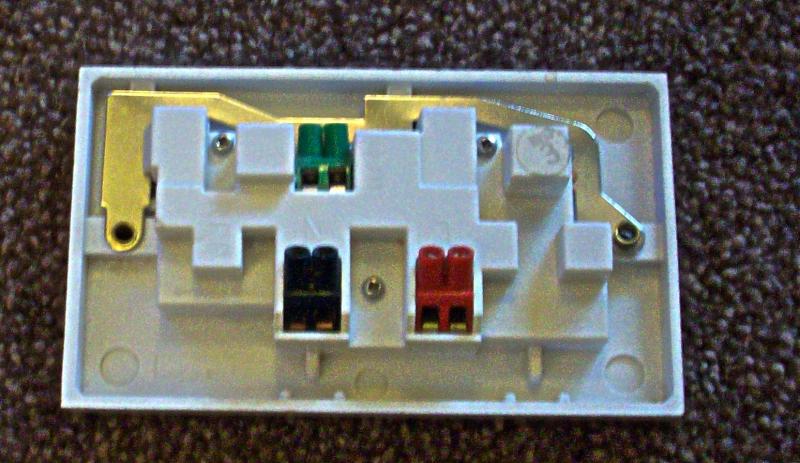

I have an MK socket here which has terminals which have a diameter of a good 5mm ...

That is theoretically enough, if the conductors are dead straight. As I illustrated, you need a minimum diameter of about 4.3mm to be able to just squeeze 4x2.5mm² conductors in. However, in practice, one is going to need a bit more than 4.3mm if it is going to be anything like an easy task to get them in (particularly if the conductors are not perfectly straight), so maybe MK feel that even ~5mm diameter is not quite enough? Who knows?!!

Anyway, regardless of their reasoning, it is clear that putting four 2.5mm² conductors (and I assume that includes 'two doubled') into one of those terminals is non-compliant with the word of the MIs

Kind Regards, John