There is a separate discussion going on as to whether Ashley’s J803 and J804 ‘maintenance-free’ junction boxes are suitable for use in inaccessible locations. However, that discussion aside, there is one point about these products which has aroused my curiosity ....

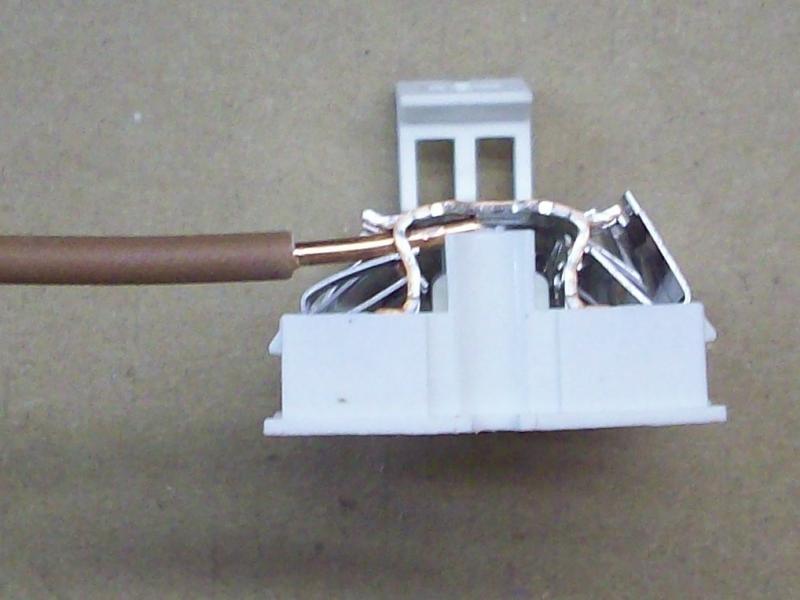

They look to be well-designed and well-engineered products; the cable clamps, pretty unique amongst JBs, are particularly welcome. The J803 and J804 are almost identical, both containing groups of four interconnected push-button-operated spring terminals, each with a specified conductor capacity of 0.5mm² – 4mm². Both say that each of the (four) cable clamps can take up to 2 x 2.5mm² T&E cables or 1 x 4mm² T&E cable. As far as I can make out, there are only two differences between the J803 and J804:

Kind Regards, John.

They look to be well-designed and well-engineered products; the cable clamps, pretty unique amongst JBs, are particularly welcome. The J803 and J804 are almost identical, both containing groups of four interconnected push-button-operated spring terminals, each with a specified conductor capacity of 0.5mm² – 4mm². Both say that each of the (four) cable clamps can take up to 2 x 2.5mm² T&E cables or 1 x 4mm² T&E cable. As far as I can make out, there are only two differences between the J803 and J804:

- 1...In the J803, one group of 4 terminals is absent (those labeled as ‘loop’/’L2’ in the J804).

2...The covers are different, but only in that the J803 has ‘32A’ on it and the J804 has ‘20A’ on it.

Kind Regards, John.