Hello

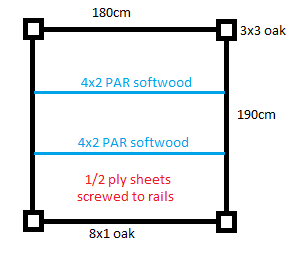

I would like to build a super king bed (6' wide by 6'3" long) from oak. I was thinking of buying 3x3 PAR oak corner posts and 8x1 PAR oak rails, joined using bed connectors. Headboard will be separate (fabric covered and wall mounted). Making the bed 6'3" long means I can use two zip& link single mattresses which will fit up the stairs.

Any suggestions on the best bed connectors? I would like to avoid (ahem) squeaking which I have experienced on previous beds that used connectors rather than bolted joints. Hafele have some and they are usually a good bet for connectors - has anyone used them?

I don't have a pillar drill so I think I would struggle to accurately make the holes for half-moon bed bolts (especially the large hole which I think would need a Forstner bit)?

I was thinking that, for simplicity and strength, I would use two centre supports at 1/3 and 2/3 spacing, 3x2 C16 timber on mini joist hangars. I would use 1/2" ply instead of slats. I can buy 6x2 ply sheets locally which means I will have less cutting as three of these should cover the base.

Doing this seems vastly cheaper than buying a comparable frame from the internet, means I can get the height exactly to our requirements and can finish it in Danish oil (our preference).

Any advice please? Picture attached.

bsr

I would like to build a super king bed (6' wide by 6'3" long) from oak. I was thinking of buying 3x3 PAR oak corner posts and 8x1 PAR oak rails, joined using bed connectors. Headboard will be separate (fabric covered and wall mounted). Making the bed 6'3" long means I can use two zip& link single mattresses which will fit up the stairs.

Any suggestions on the best bed connectors? I would like to avoid (ahem) squeaking which I have experienced on previous beds that used connectors rather than bolted joints. Hafele have some and they are usually a good bet for connectors - has anyone used them?

I don't have a pillar drill so I think I would struggle to accurately make the holes for half-moon bed bolts (especially the large hole which I think would need a Forstner bit)?

I was thinking that, for simplicity and strength, I would use two centre supports at 1/3 and 2/3 spacing, 3x2 C16 timber on mini joist hangars. I would use 1/2" ply instead of slats. I can buy 6x2 ply sheets locally which means I will have less cutting as three of these should cover the base.

Doing this seems vastly cheaper than buying a comparable frame from the internet, means I can get the height exactly to our requirements and can finish it in Danish oil (our preference).

Any advice please? Picture attached.

bsr