- Joined

- 23 Jun 2018

- Messages

- 74

- Reaction score

- 0

- Country

Hi,

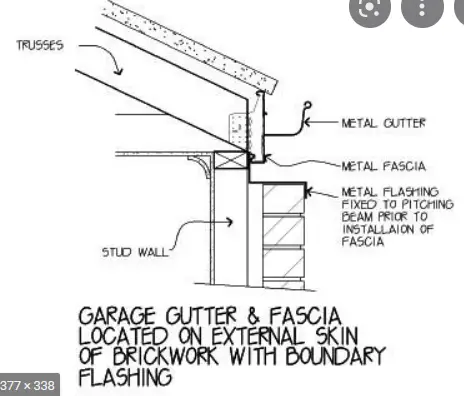

Wondering if someone can help me with a gutter situation. I have a cavity wall on a kitchen extension, and the outer wall is on the boundary and I don't wish the gutter to overhang into the neighbours land.

I've seen box butter but these are when there is a parapet wall, the external wall at the moment is the same height as the internal wall and will need to be finished.

I was looking around and found the following design as per picture. It looks easier and cheaper as I can use a standard PVC gutter and all I will need to do is add some sort of metal flashing over the cavity. Is this feasible, otherwise I will need to build a box and line it with lead which is a bit more complex.

Wondering if someone can help me with a gutter situation. I have a cavity wall on a kitchen extension, and the outer wall is on the boundary and I don't wish the gutter to overhang into the neighbours land.

I've seen box butter but these are when there is a parapet wall, the external wall at the moment is the same height as the internal wall and will need to be finished.

I was looking around and found the following design as per picture. It looks easier and cheaper as I can use a standard PVC gutter and all I will need to do is add some sort of metal flashing over the cavity. Is this feasible, otherwise I will need to build a box and line it with lead which is a bit more complex.