Hi all, firstly apologies for the lengthy post, and if I’m not explaining the situation well – this is my first build and although I’ve read a lot on both this forum and others, a lot of this is still fairly new to me!

I'm currently in the middle of building a shed, that essentially will be a compromise of trying to fit all of my bulky tools and other items that we currently have in the house, and a gap of c. 2.7mx2m between fence panels on 2 sides and a tree on another.

As such, I've settled on a 2.44x1.84m framed shed, with a planned 10cm overhang on the eaves.

The frames for the floor and the walls have been constructed. For the sides that are nearest the fence panels, I plan to clad in 15mm structural ply, whilst the visible faces will be clad in shiplap.

I’m aware that it's rather late to be making changes in the build stage, but I’ve just been considering whether the stuff we’re storing might end up being subject to some rust in the shed’s current form.

Big-all has been extremely helpful already in suggesting that I put a breathable membrane in along with some battens, which is a plan I’m currently considering (whilst being mindful that any further expansion of the shed footprint is going to be tight!).

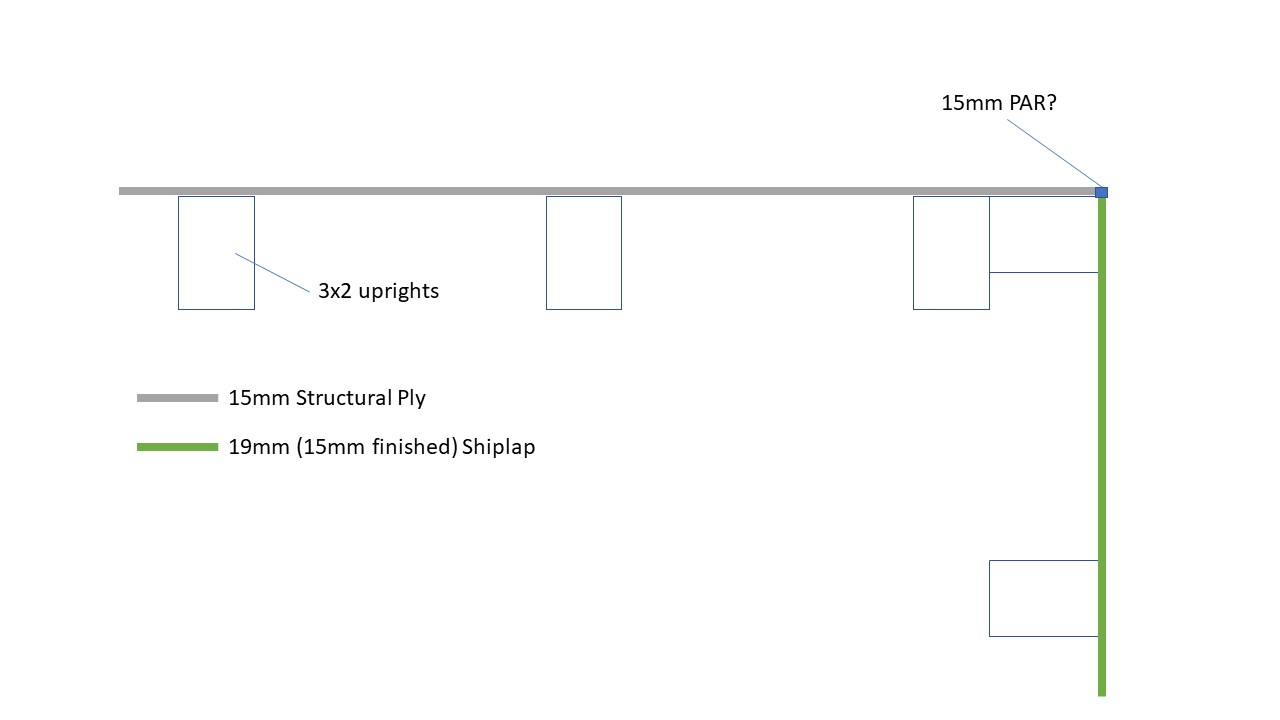

So, current shed plan:

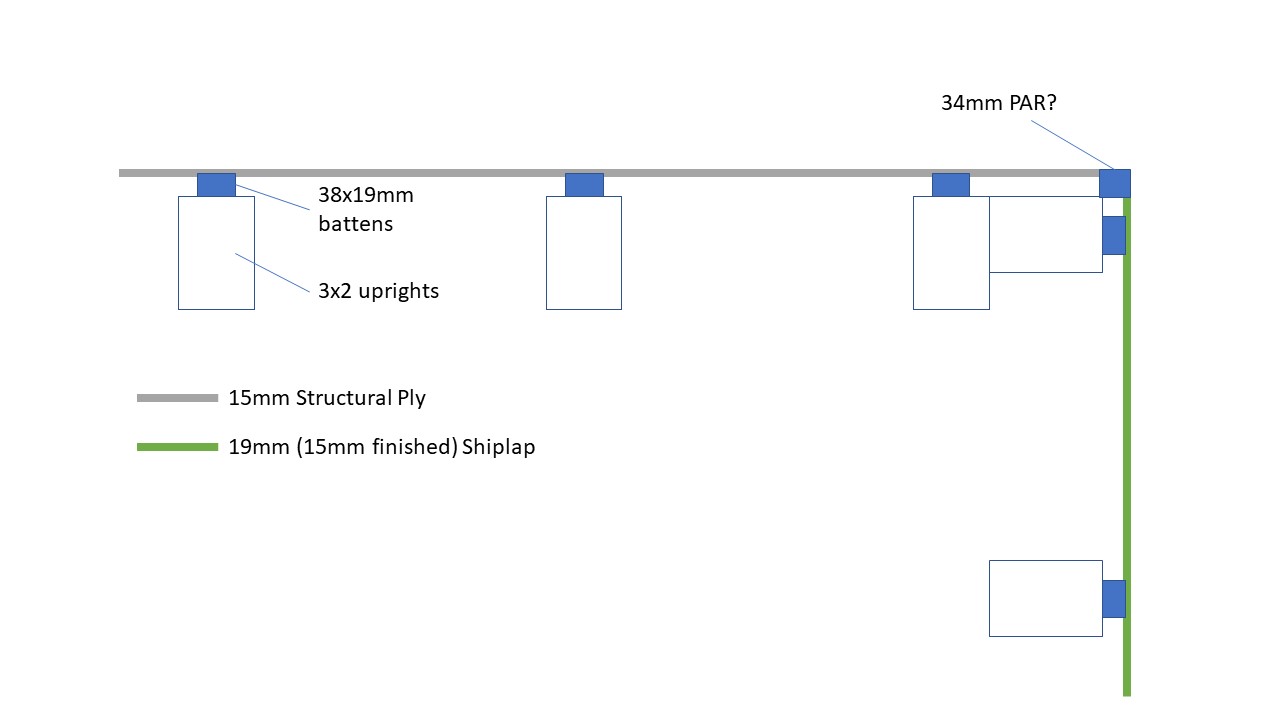

Proposed shed plan:

A couple of questions:

Corners: I’d always anticipated putting in 15mm finishing strips to each side, to protect the ends of the shiplap and ply. Given that the shed length will be 2.44m which fits my sheet ply exactly, do I continue with this length, even once I add battens? Then, when the walls come further out of the frame, I would just add thicker wood as a finishing strip?

Door frame: at present, I had expected to double up on the 3x2 stud nearest where I plan to put the door. If the cladding starts to move further away from the studs, I expect that I’ll also need to move the second stud nearer to the exterior, so that I have something solid to screw into?

Bottom of shed: at the moment, the walls sit flush with the shed base. When I put vertical battens in to provide the air gap between the membrane and the cladding, what happens to the base (i.e. I’d have a 19mm gap where I can see the ground now?)

Many thanks in advance, if there are any questions, please shout and I’ll do my best to clarify!!

I'm currently in the middle of building a shed, that essentially will be a compromise of trying to fit all of my bulky tools and other items that we currently have in the house, and a gap of c. 2.7mx2m between fence panels on 2 sides and a tree on another.

As such, I've settled on a 2.44x1.84m framed shed, with a planned 10cm overhang on the eaves.

The frames for the floor and the walls have been constructed. For the sides that are nearest the fence panels, I plan to clad in 15mm structural ply, whilst the visible faces will be clad in shiplap.

I’m aware that it's rather late to be making changes in the build stage, but I’ve just been considering whether the stuff we’re storing might end up being subject to some rust in the shed’s current form.

Big-all has been extremely helpful already in suggesting that I put a breathable membrane in along with some battens, which is a plan I’m currently considering (whilst being mindful that any further expansion of the shed footprint is going to be tight!).

So, current shed plan:

Proposed shed plan:

A couple of questions:

Corners: I’d always anticipated putting in 15mm finishing strips to each side, to protect the ends of the shiplap and ply. Given that the shed length will be 2.44m which fits my sheet ply exactly, do I continue with this length, even once I add battens? Then, when the walls come further out of the frame, I would just add thicker wood as a finishing strip?

Door frame: at present, I had expected to double up on the 3x2 stud nearest where I plan to put the door. If the cladding starts to move further away from the studs, I expect that I’ll also need to move the second stud nearer to the exterior, so that I have something solid to screw into?

Bottom of shed: at the moment, the walls sit flush with the shed base. When I put vertical battens in to provide the air gap between the membrane and the cladding, what happens to the base (i.e. I’d have a 19mm gap where I can see the ground now?)

Many thanks in advance, if there are any questions, please shout and I’ll do my best to clarify!!